Parallel connection starting device for starting internal combustion engine

A technology of starting internal combustion engine and starting device, which is used in the direction of engine motor starting, engine components, engine starting, etc., which can solve problems such as milling and broken teeth, to reduce the effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

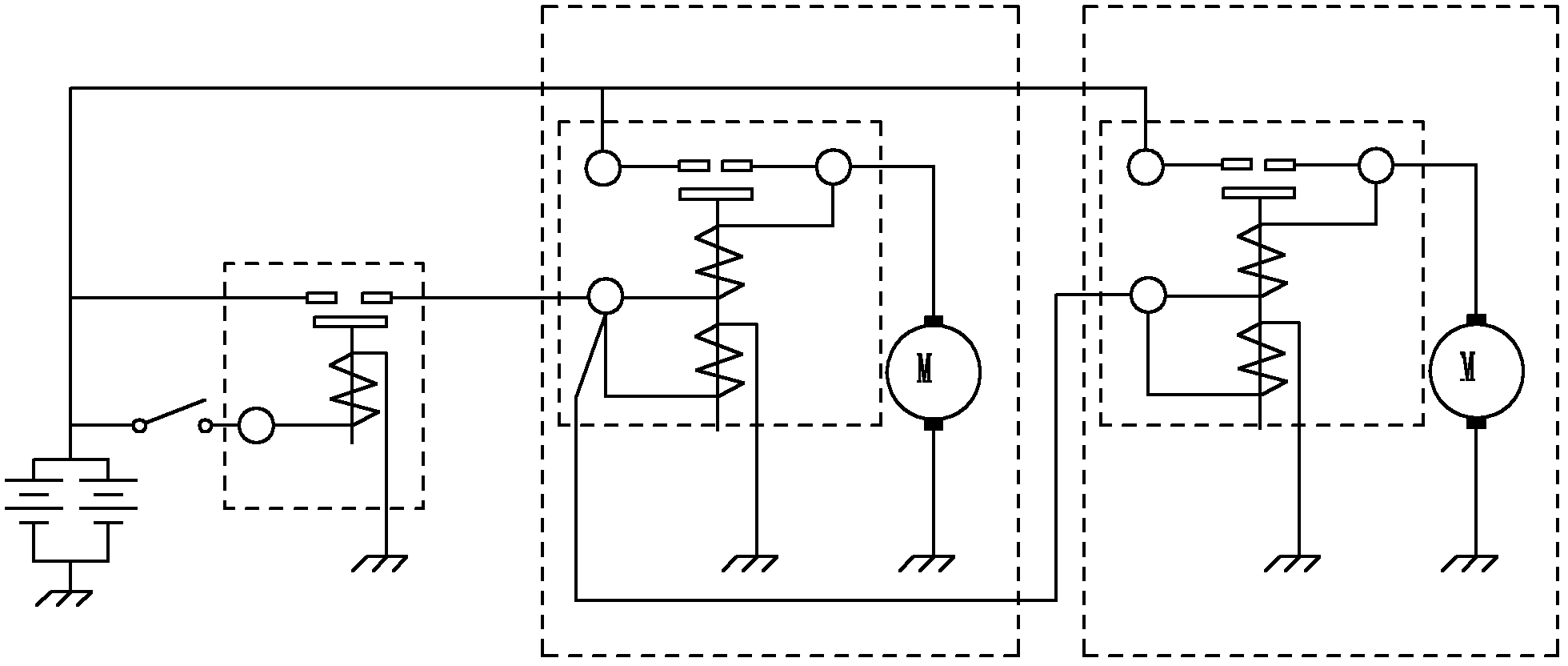

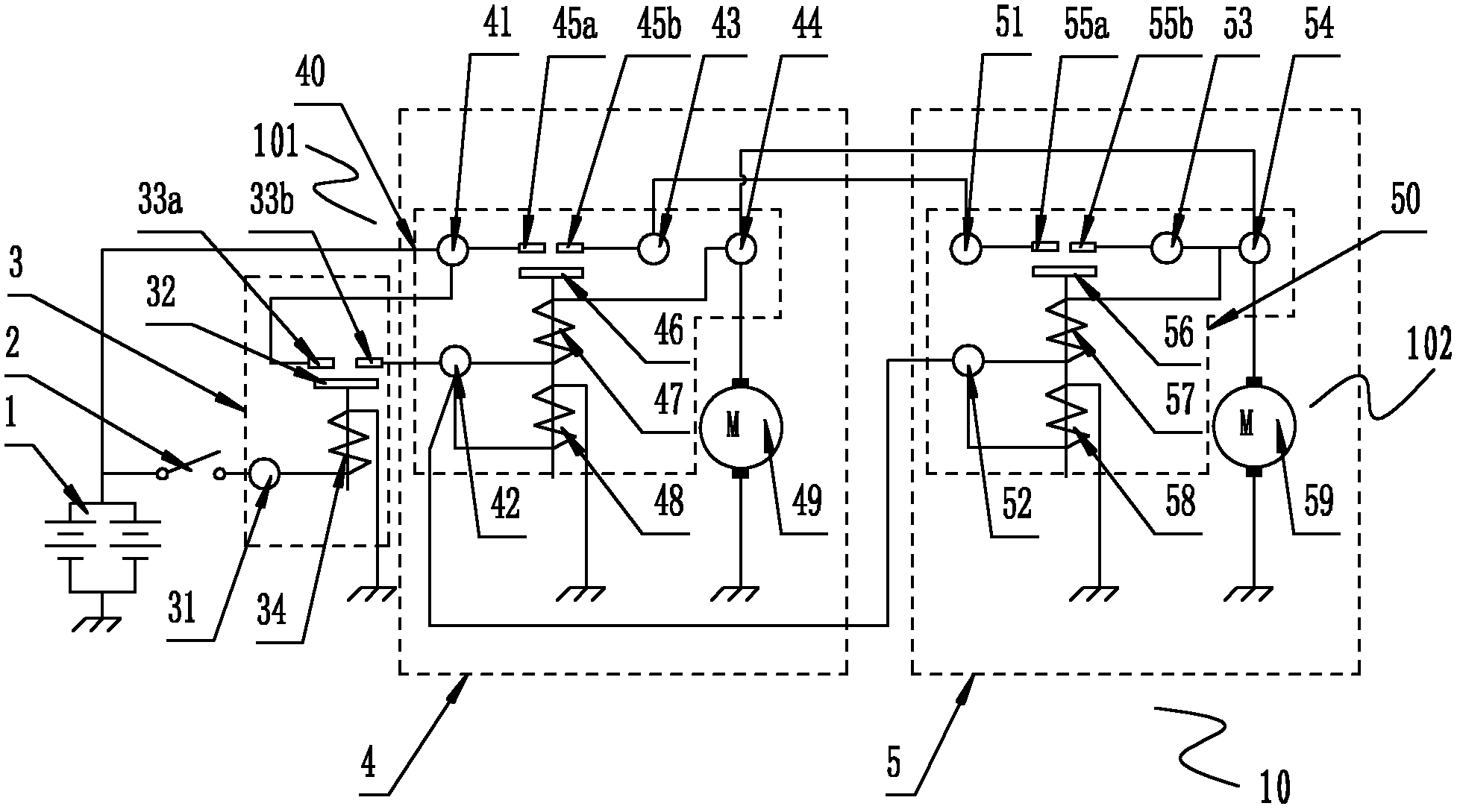

[0066] image 3 A circuit diagram of a first embodiment of the present invention is shown in . Parallel starting device among the figure has accumulator battery group 1 that is connected in parallel again after accumulator two in series, control switch 2 (is the key door switch in the present embodiment), two parallel starters 4 and 5 and a starter relay 3. The starter 4 includes a suction coil 47, a holding coil 48, a battery terminal 41, a switch terminal 42, a motor terminal 43, a machine terminal 44, a movable contact 46 and an electromagnetic switch 40 of two static contacts 45a, 45b, and a motor 49. The starter 5 includes a magnetic switch 50 with a suction coil 57, a holding coil 58, a battery terminal 51, a switch terminal 52, a motor terminal 53, a motor terminal 54, a movable contact 56 and two static contacts 55a, 55b, and a motor 59. The starter relay 3 includes a relay terminal 31, a coil 34, a movable contact 32 and two stationary contacts 33a and 33b.

[006...

no. 2 example

[0072] see Figure 5 , Figure 5 Shown is a second embodiment of the patent of the invention. In this embodiment, the electromagnetic switch 50 of one of the parallel starters 5 only has switch terminals 52, battery terminals 51 and motor terminals 53, and no motor terminals 54 are provided. Other parts and circuits are the same as in the first embodiment.

[0073] The working process of the parallel starting device in this embodiment is the same as that in the first embodiment, and will not be repeated here.

[0074] The advantage of the second embodiment is that the parts used can be reduced and the stability of the whole system can be improved without affecting the system function.

no. 3 example

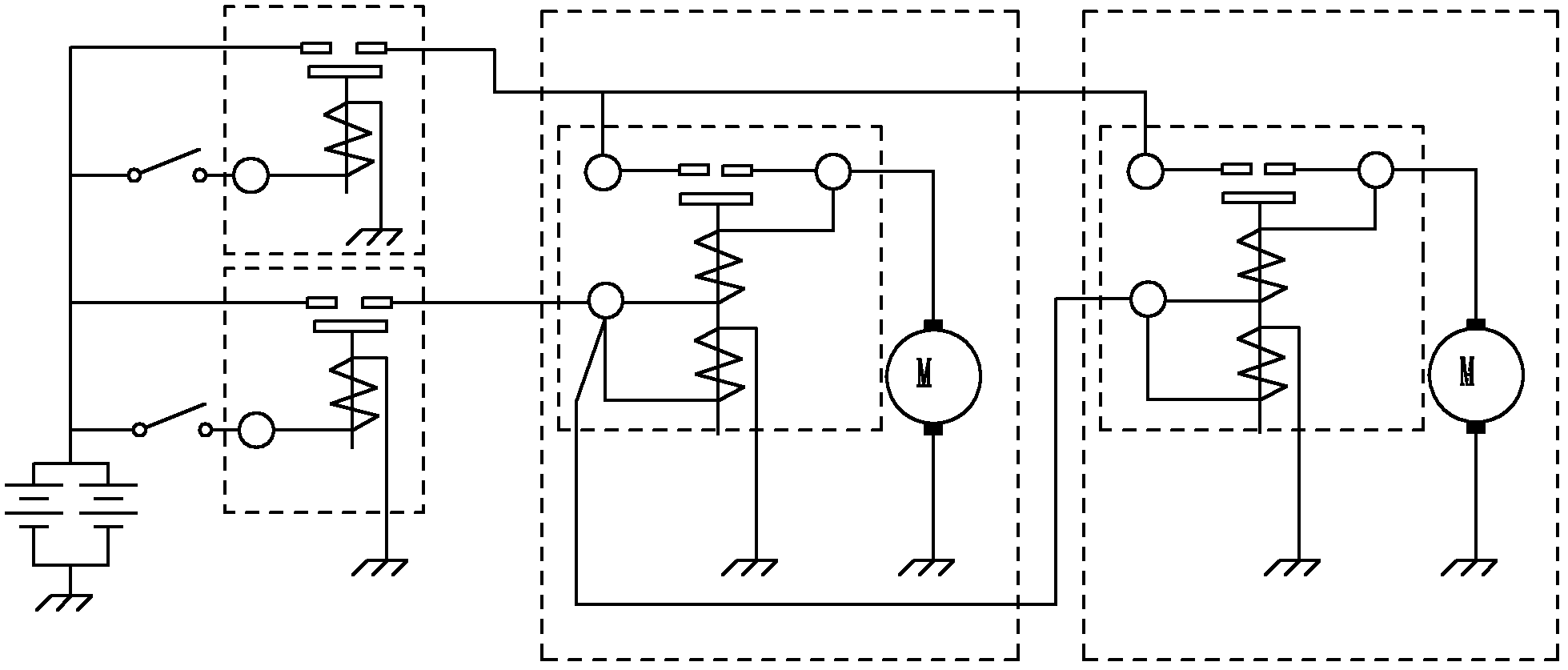

[0076] see Image 6 , Image 6 Shown is the third embodiment of the patent of the present invention. In this embodiment, each starter in the parallel starting device is equipped with a starter relay, for example, the first starter relay 30a in the figure controls the starter 4, the second starter relay 30b controls the starter 5, and the first starter relay 30a The relay terminal 31 of the first starting relay 30b is connected in parallel with the relay terminal 31 of the second starting relay 30b, and the static contact 33a of the first starting relay 30a is also connected in parallel with the static contact 33a of the second starting relay 30b. During the starting process, each starting relay controls the electromagnetic switch corresponding to the starter. Other than that, the working process is the same as that of the first embodiment.

[0077] The advantage of the third embodiment is that it is not necessary to redesign the high-current relay, and it is beneficial to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com