Tube-framework plastic composite tube and producing process thereof

A composite pipe and plastic technology, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of limited pressure, low production efficiency and high product cost, and achieve improved pressure bearing capacity and high production efficiency. , The effect of strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

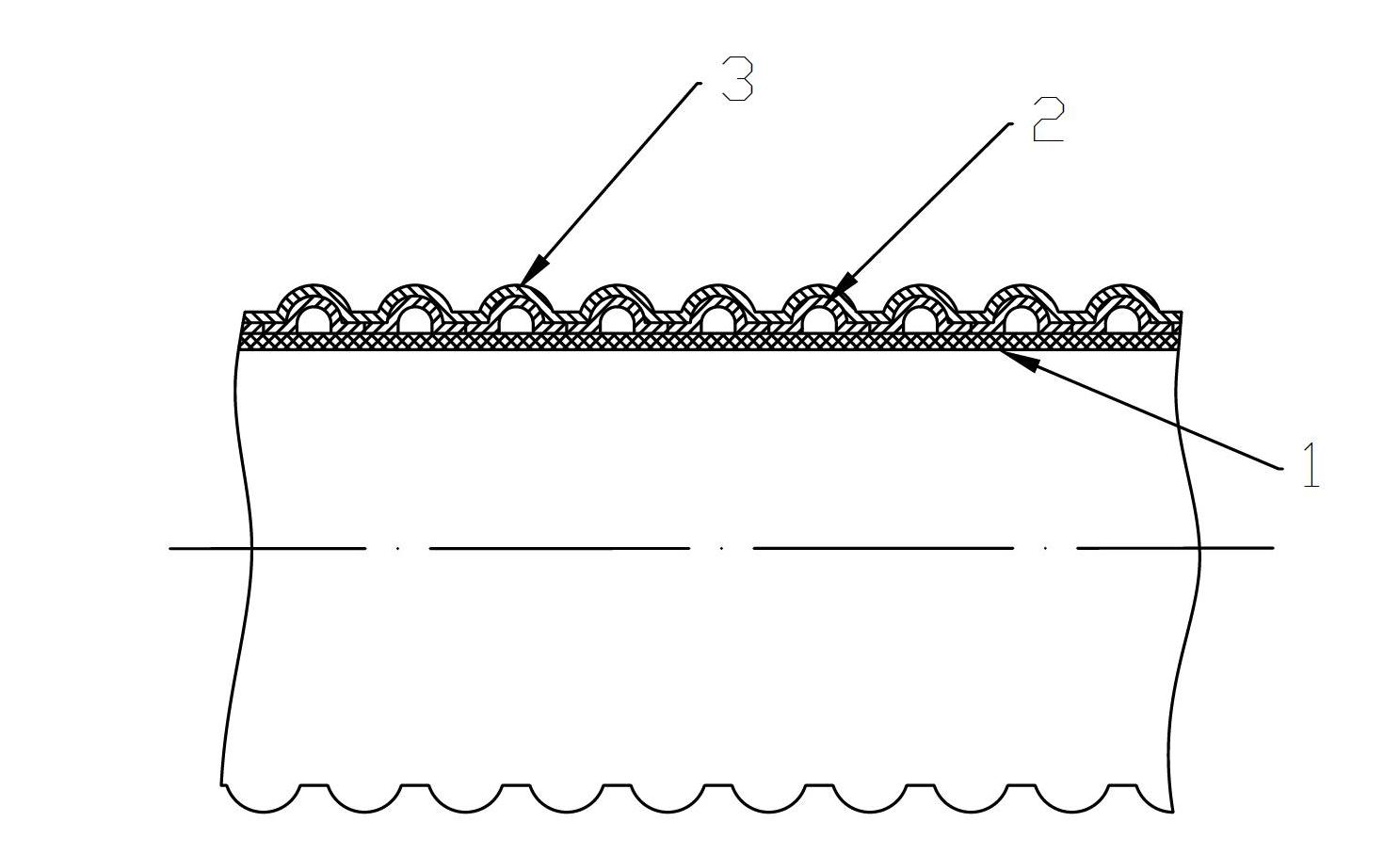

[0027] Such as figure 1 As shown, the winding structure wall 2 is a strip-shaped profile.

Embodiment 2

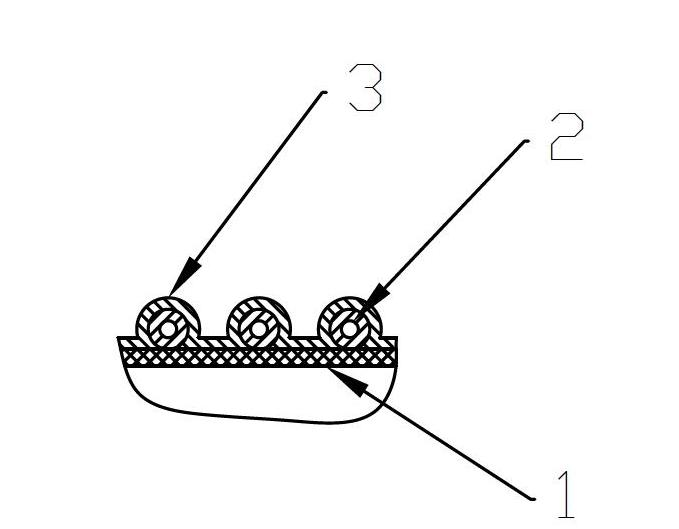

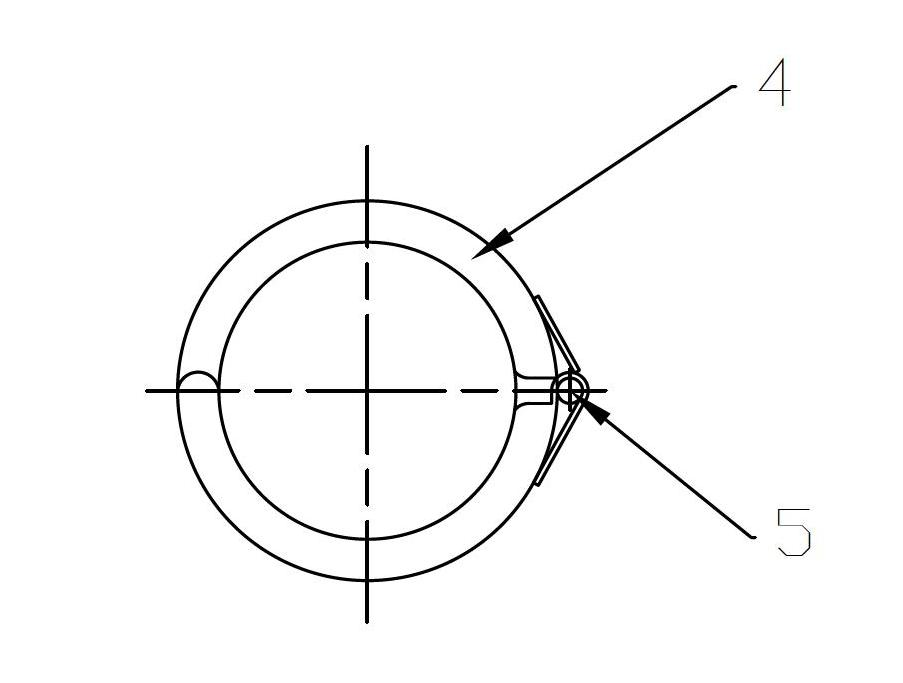

[0029] Such as figure 2 As shown, the winding structure wall 2 is a hollow tubular profile made of metal or non-metal.

[0030] Such as Figure 4 Shown, the production technology of pipe skeleton plastic composite pipe of the present invention is characterized in that, comprises the following steps:

[0031] ①The extruder extrudes the integrally formed thin-walled tube, which is vacuum shaped and cooled to form the internal pressure tube 1;

[0032] ② Use a mold to round the tube body of the internal pressure tube 1, and control its out-of-roundness within 1.5%, and wrap the winding structure wall 2 in a spiral shape on the outer surface of the internal pressure tube 1 according to a certain pitch to complete the winding structure wall 2 combined with the internal pressure tube 1;

[0033] ③ Extruding the plastic material in the molten state by the extruder, after the plastic material is extruded, it is evenly wrapped around the outside of the internal pressure pipe 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com