Backlight module and LCD (liquid crystal display)

A technology of liquid crystal display and backlight module, applied in the direction of instruments, optics, light guide, etc., can solve the problems affecting the coupling efficiency, the minimum coupling distance between the light source and the light guide plate cannot be guaranteed, etc., and achieve the effect of ensuring the coupling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be practiced.

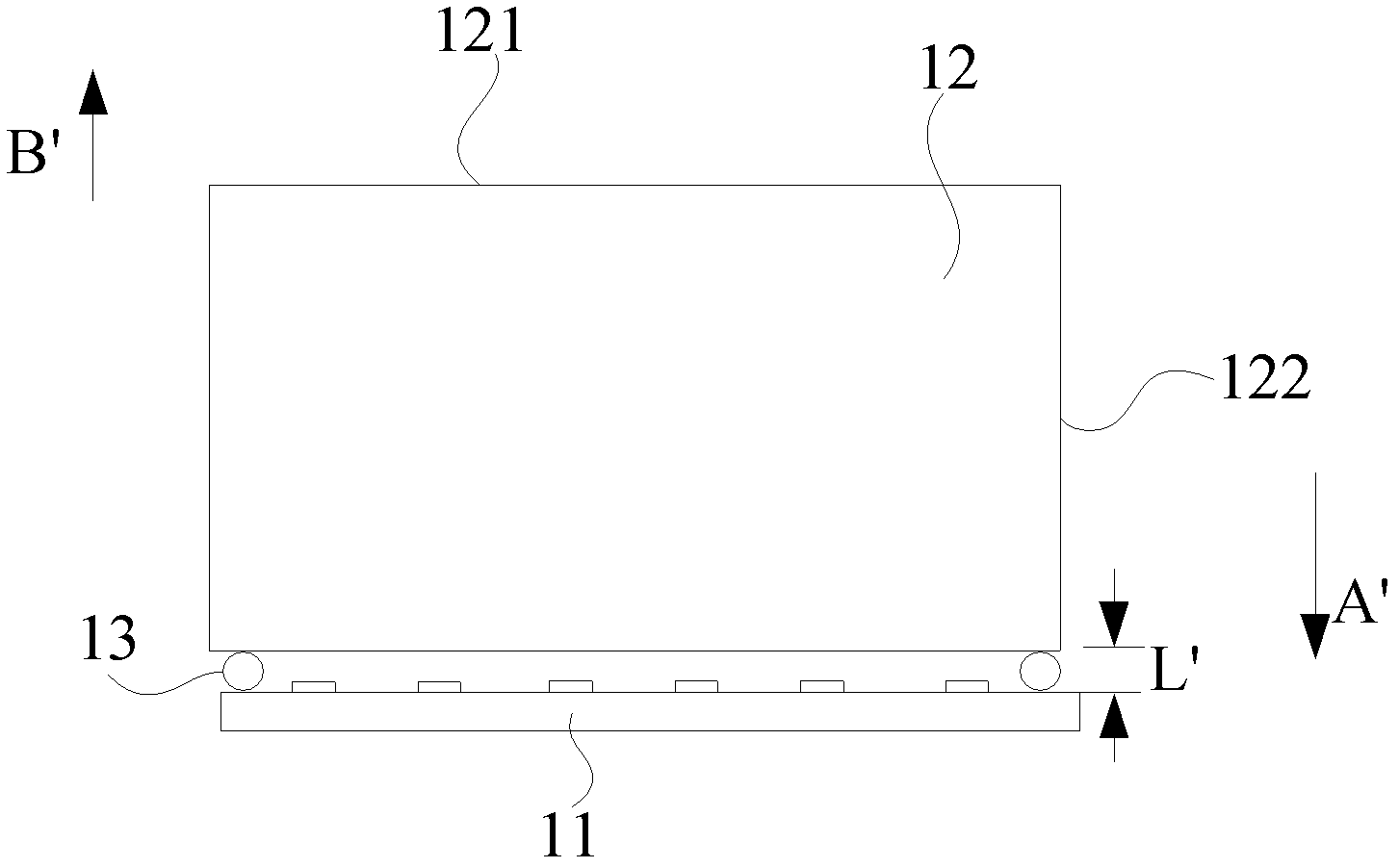

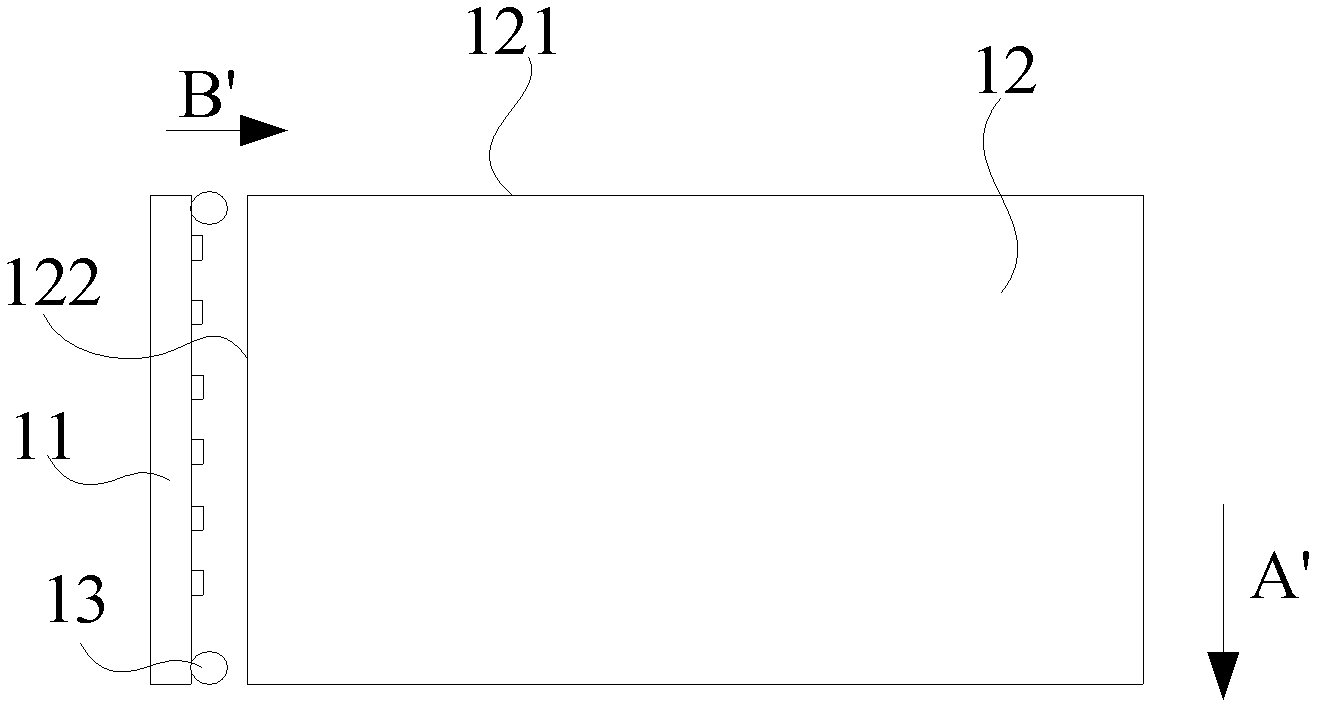

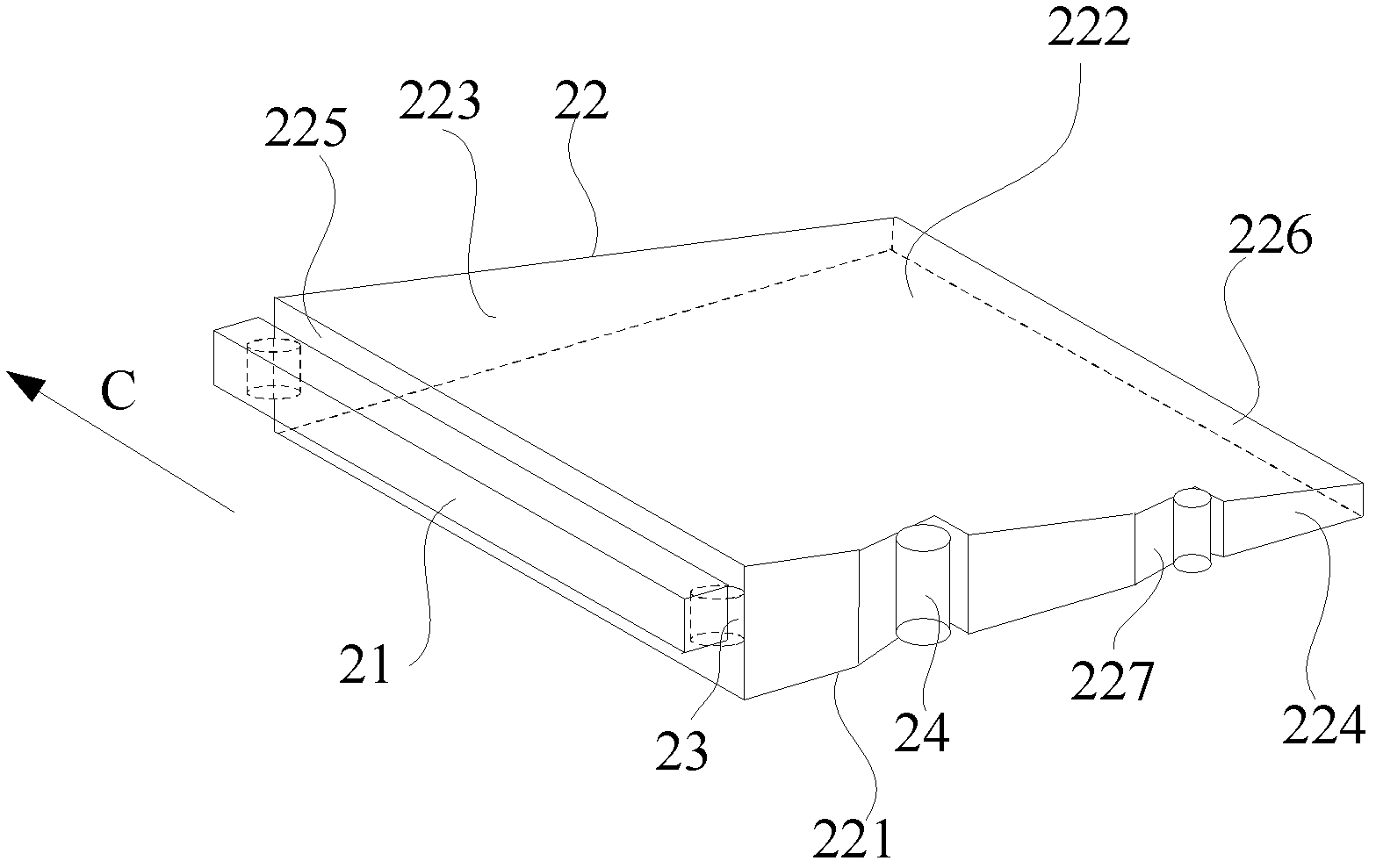

[0038] see image 3 , image 3 It is a structural schematic diagram of the first preferred embodiment of the backlight module in the present invention, Figure 4 for image 3 top view. The backlight module includes a light source 21 , a light guide plate 22 , a positioning column 23 and a supporting column 24 .

[0039] The light guide plate 22 includes a reflective surface 221 and a light-emitting surface 222, between which the reflective surface 221 and the light-emitting surface 222 include an upper bottom surface 223 and a supporting bottom surface 224, and also includes a left side 225 and a right side 226, wherein, The length of the upper bottom surface 223 or the supporting bottom surface 224 is greater than the length of the left side 225 or the right side 226 .

[0040] The support bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com