Laser distance measurement-source device for pipeline radiographic inspection

A technology of ray flaw detection and laser ranging, which is applied to measuring devices, material analysis using wave/particle radiation, instruments, etc., to achieve accurate and reliable distances, stable erection, and accurate and effective ranging readings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

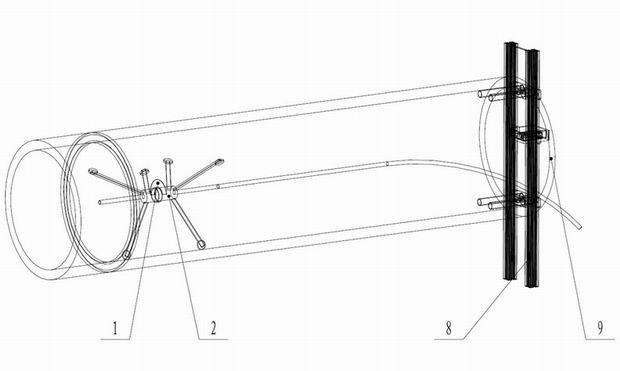

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

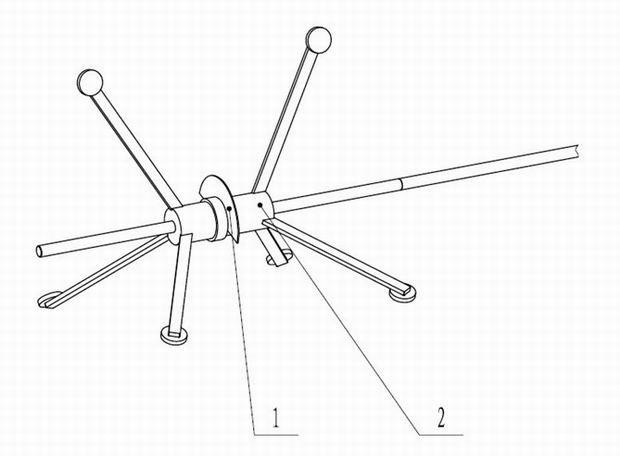

[0023] The present invention cooperates crawler 2 to use, as figure 1 As shown, a reflector 1 is installed on the crawler 2. The reflector 1 is fastened on the crawler 2 by means of a clamp, and its reflective surface is perpendicular to the axis of the crawler 2, and is used to record the distance from the reflective surface of the reflector 1 to the probe.

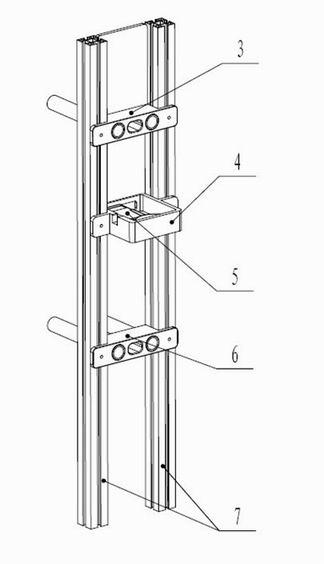

[0024] The present invention includes an auxiliary aiming bracket 8, which is used in conjunction with a laser range finder, such as figure 2 shown. Auxiliary aiming bracket 8 is mainly made of rail frame 7, upper clip 3, lower clip 6, rangefinder bracket 4. The upper clamp 3, the lower clamp 6 and the rangefinder bracket 4 can be adjusted up and down on the rail frame 7. The size of the auxiliary aiming frame 8 is specially designed to ensure that when the laser rangefinder 5 is installed in the rangefinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com