Multifunctional concealed wire box of electric vehicle

A multi-functional, electric vehicle technology, applied in electrical components and other directions, can solve the problems of reducing the service life of the wiring harness, aging of the wiring harness, etc., and achieve the effect of saving costs and reducing manufacturing hours.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

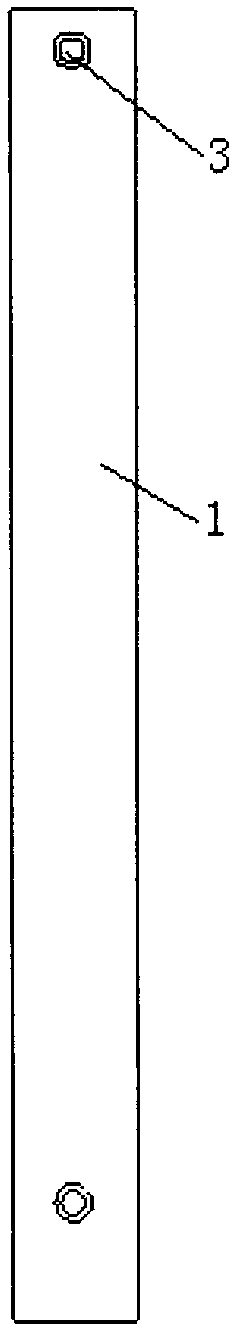

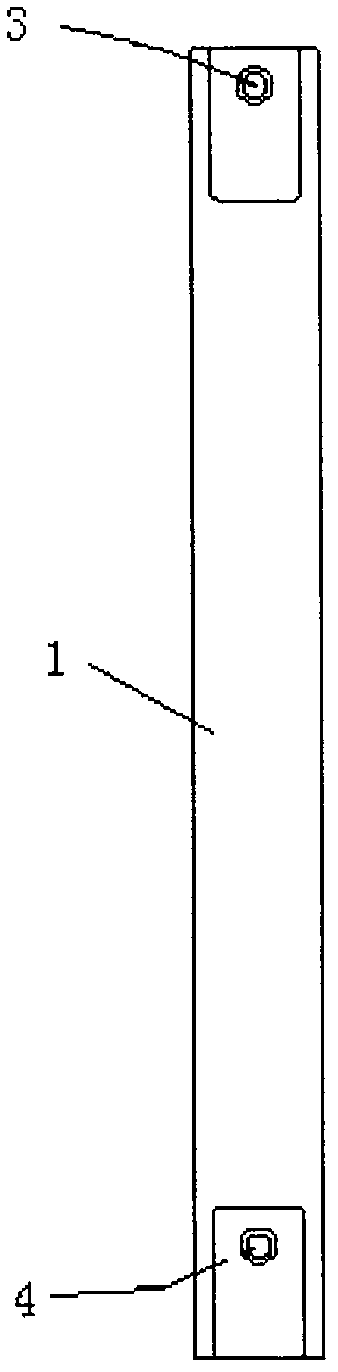

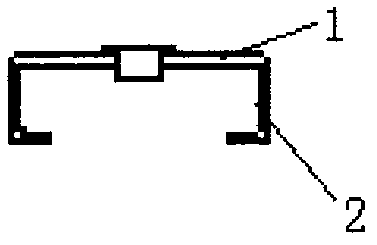

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as Figure 1-3 As shown, the wire harness box 1 is integrated with the battery box slideway 2, the upper surface of the wire harness box is used as the bottom surface of the battery box slideway, and the upper and lower surfaces of the wire harness box are respectively provided with internal threads 3 for fastening screws. Both ends of the lower surface of the wire harness box are respectively provided with threading holes 4 for passing in and out of the wire harness.

[0014] By hiding the wire box, it not only reduces the man-hours, prevents the aging of the wire harness, and integrates the multi-functional slideways, but also improves the refinement of the overall manufacturing process and the beautiful appearance of the electric vehicle. It really hides all the wire harnesses and gets a lot of benefits. good protection.

[0015] The above-mentioned em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com