Integrated viscous clutch

A clutch and viscous technology, applied in clutches, fluid clutches, fluid-driven clutches, etc., can solve problems such as wire failures and shortened bearing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

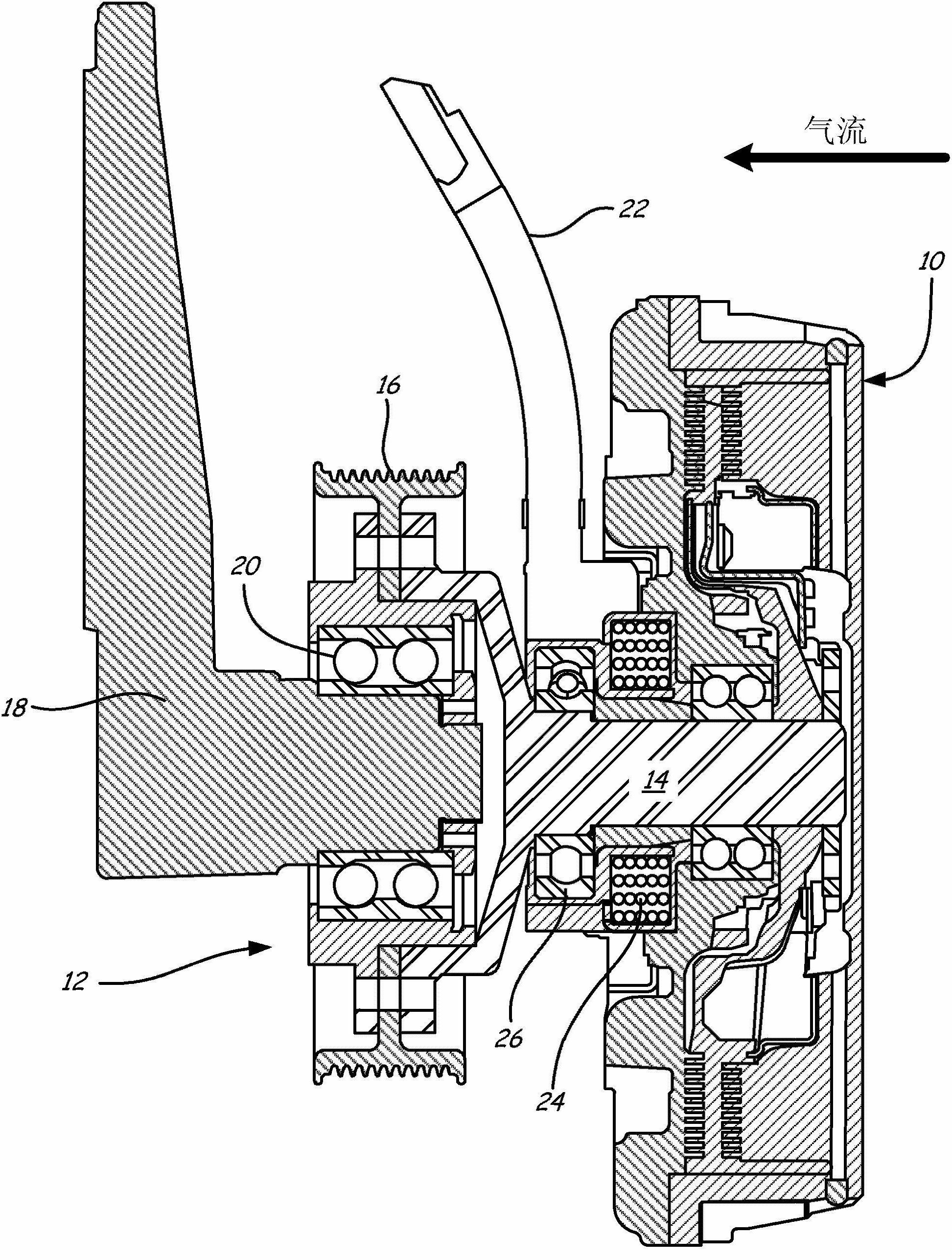

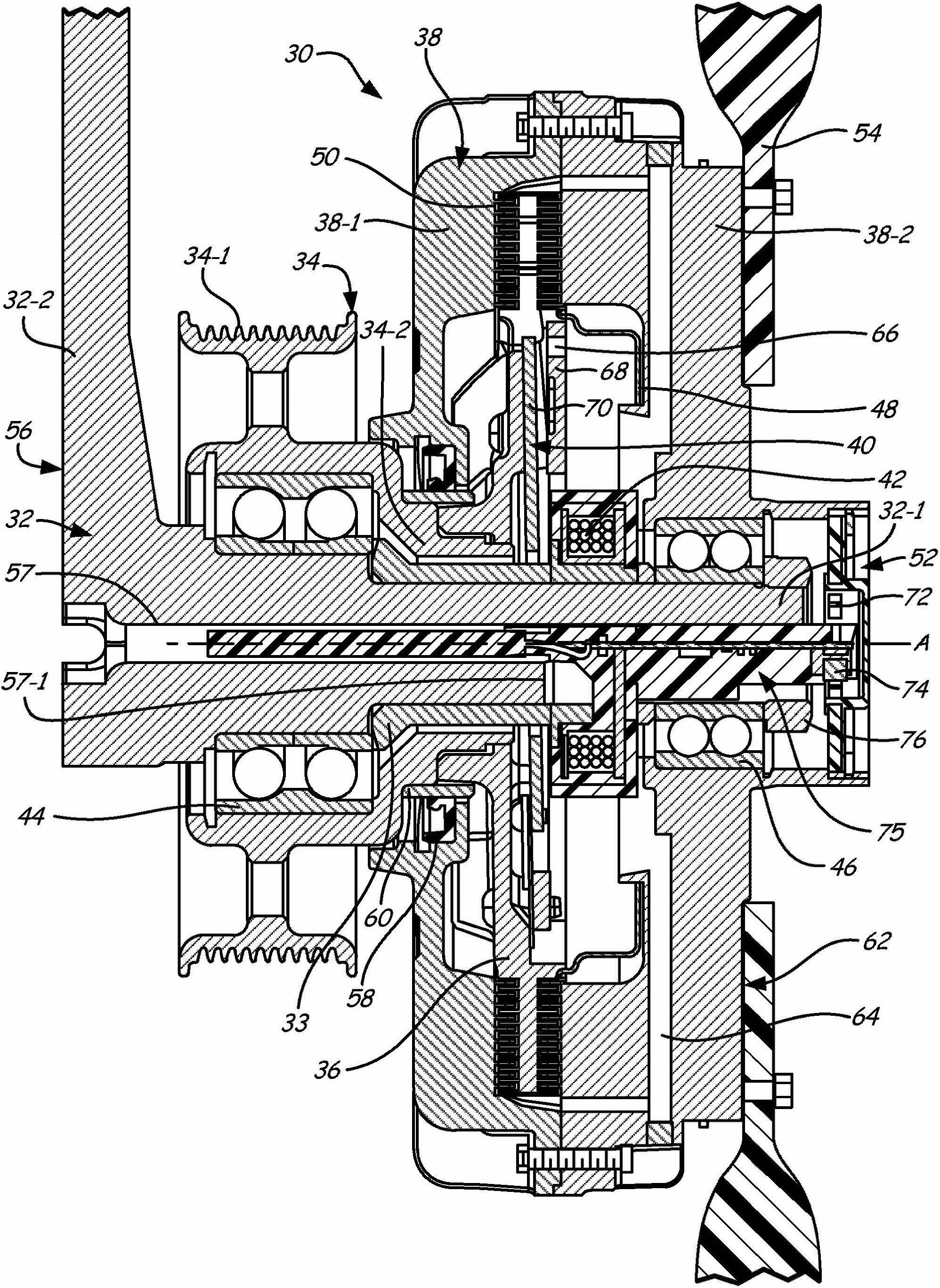

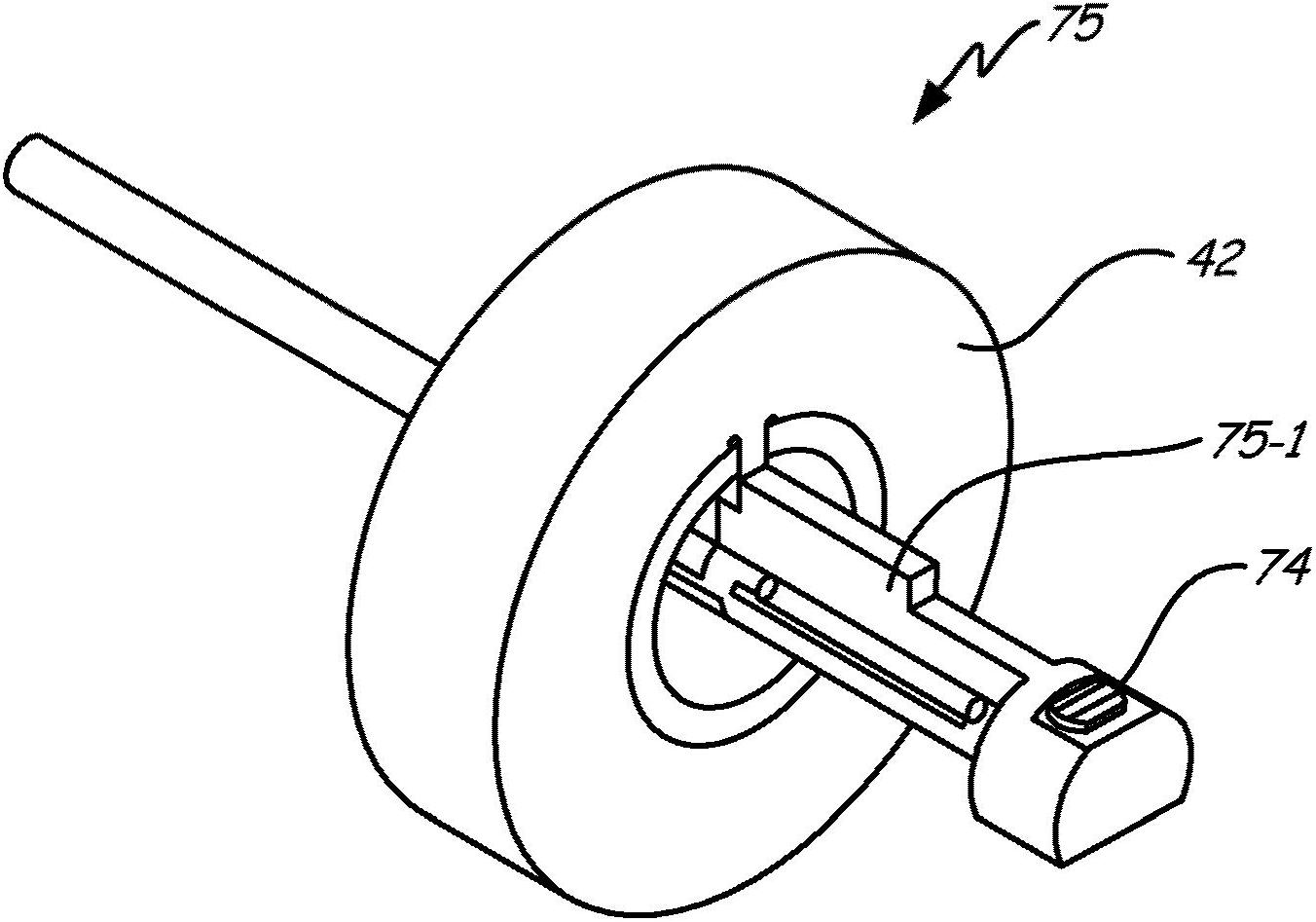

[0014] The present invention is a viscous clutch assembly that allows good packaging, power dissipation and system support and is suitable as a fan clutch in automotive applications. In general, a clutch (or driver) includes a mounting shaft (synonymously called a journal bracket) that may extend between the front and rear faces along the axial length of the clutch. Mounting shafts are designed to serve a variety of purposes, including providing support for fans, housings, rotors, pulleys (synonymously called sheaves) and solenoid coils, providing a conduit path for electrical control wires, and optionally A portion of the magnetic flux circuit for actuation of the valve is provided. All these functions are combined in the mounted shaft, allowing a very compact design and eliminating a considerable number of components compared to conventional viscous clutch and hub arrangements. In addition, the clutch of the present invention allows the electromagnetic coil to be positioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com