Seedling collection facility for rapana venosa factory seed culture

A factory-like, veined red snail technology, applied in the direction of climate change adaptation, fish farming, application, etc., can solve the problems of seedling failure, water quality deterioration, larvae death, etc., and achieve increased survival rate, increased survival rate, and larval survival rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The method for picking seedlings of red snail industrialized seedling cultivation of the present invention, concrete process is as follows:

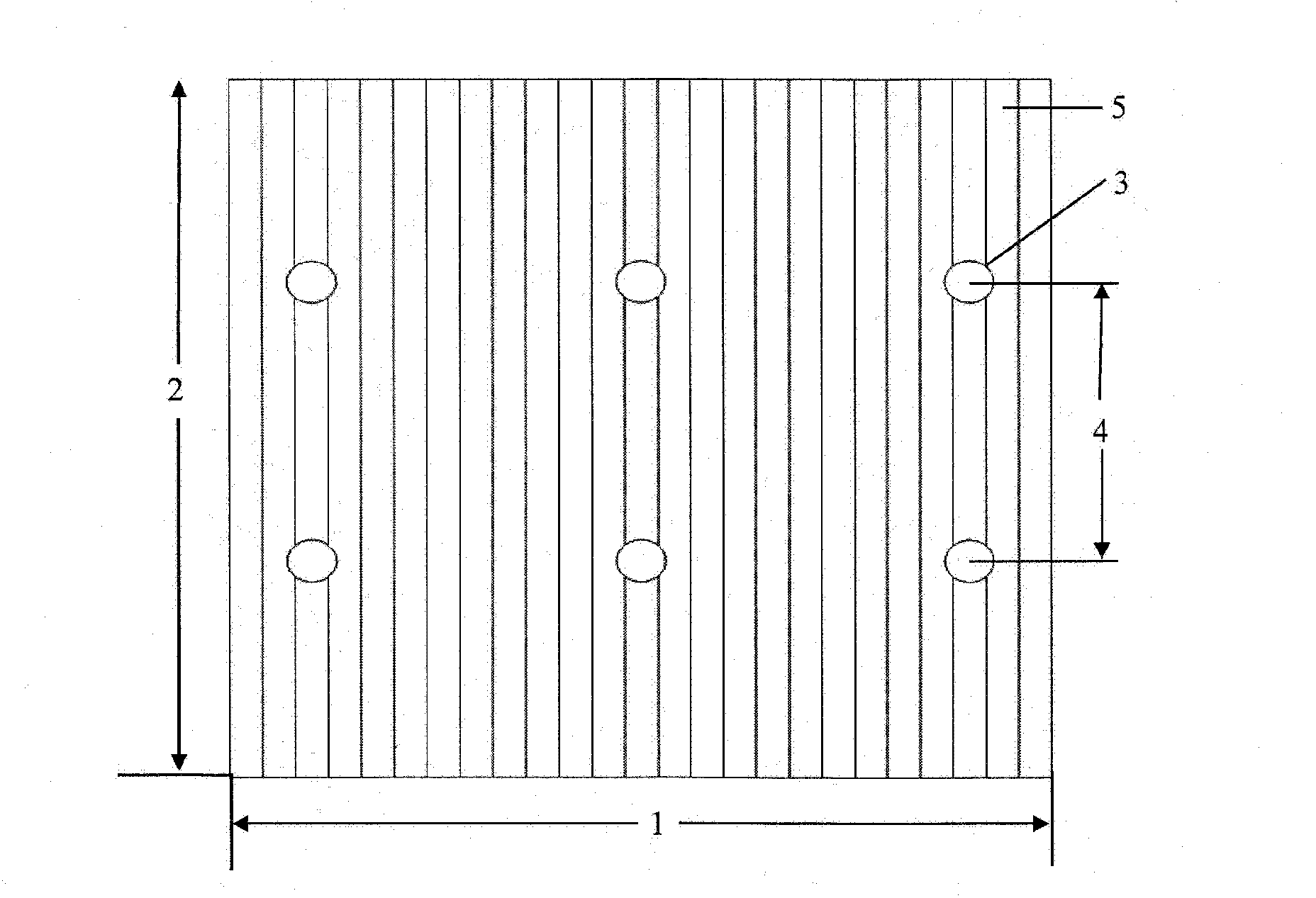

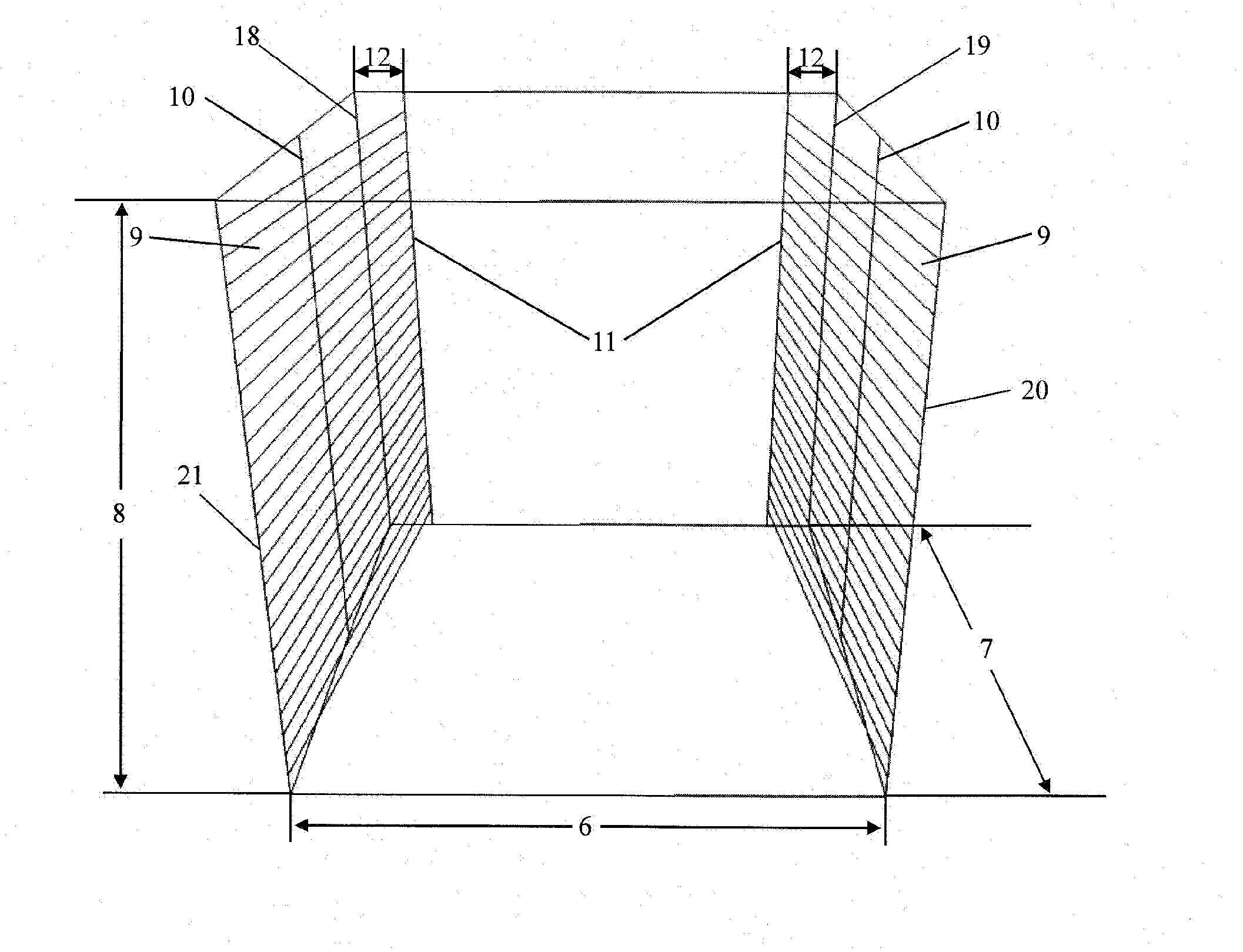

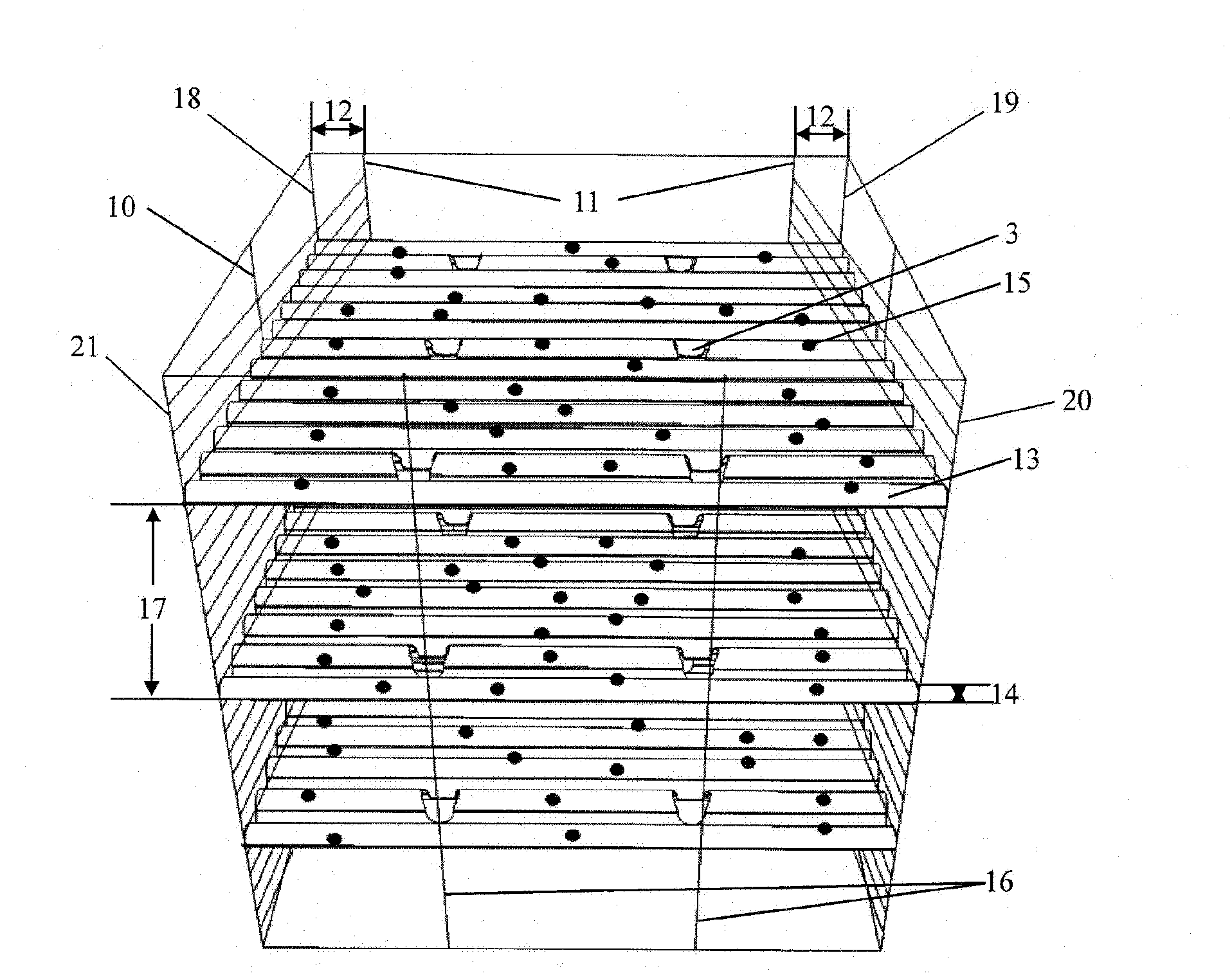

[0029] The seedling picking facilities are made of rough plastic corrugated boards and brackets that fix the corrugated boards. Before the seedling picking facilities are released, oyster spat are attached to the plastic corrugated boards as animal bait during the feeding habits conversion and metamorphosis of the snail larvae. , the density of oyster spat on the plastic corrugated board is 5-20 / cm 2 , The size of oyster spat is 0.5-2.0mm in shell length. When more than 50% of the red snail larvae develop to the late stage of the third helix to the early stage of the fourth helix, put the seedling collection facilities in a multi-plane and three-dimensional layered manner with plastic corrugated plates in the seedling pond, so as to make full use of the water body and make the red snail The larvae attach to the plastic corrugated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com