Liquid eyeliner discharge structure

A technology of eyeliner and bottle cap, which is applied in the field of liquid eyeliner discharge structure, can solve the problems of inconvenient use, too much or too little material body, and achieve the effect of convenient and reliable use and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

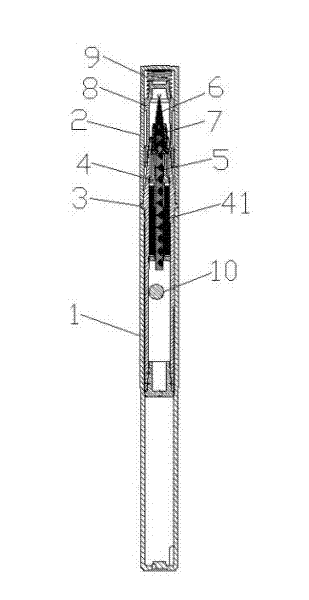

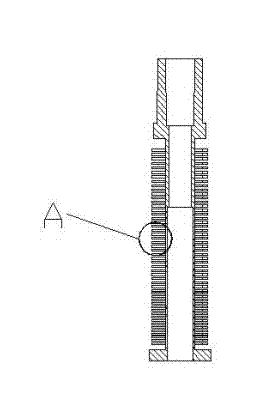

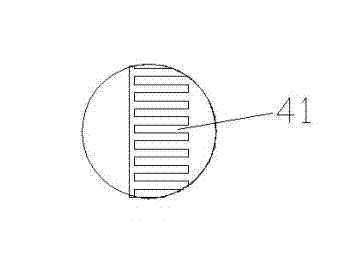

[0024] An eyeliner liquid discharge structure, which includes a bottle body 1, a bottle cap 2, a brush cover seat 3, a diverter seat 4, a water diversion core 5 and bristles 6, the bristles are arranged at one end of the water diversion core; On the outer periphery of the water diversion core, and the bristles expose one end of the diverter seat (the exposed part includes the bristle tip and the foam tip); the diverter seat is provided with several material storage holes 41; the brush cover seat is fixed On the periphery of the diverter seat; the bottle cap is detachably arranged outside one end of the brush holder, and the bottle body is detachably arranged outside the other end of the brush holder. When in use, the material body (liquid eyeliner) is contained in the brush cover seat, and then the bottle cap is removed, and the material body (liquid eyeliner) flows from the bottle body through the diverter seat to the bristles or foaming pen along the water diversion core. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com