Multi-inner tube combination tyre

A technology of combining tires and multiple inner tubes, which is applied in directions with multiple inflatable chambers, can solve problems such as loss of control and danger, and achieve the effect of facilitating installation and maintaining tire elasticity and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

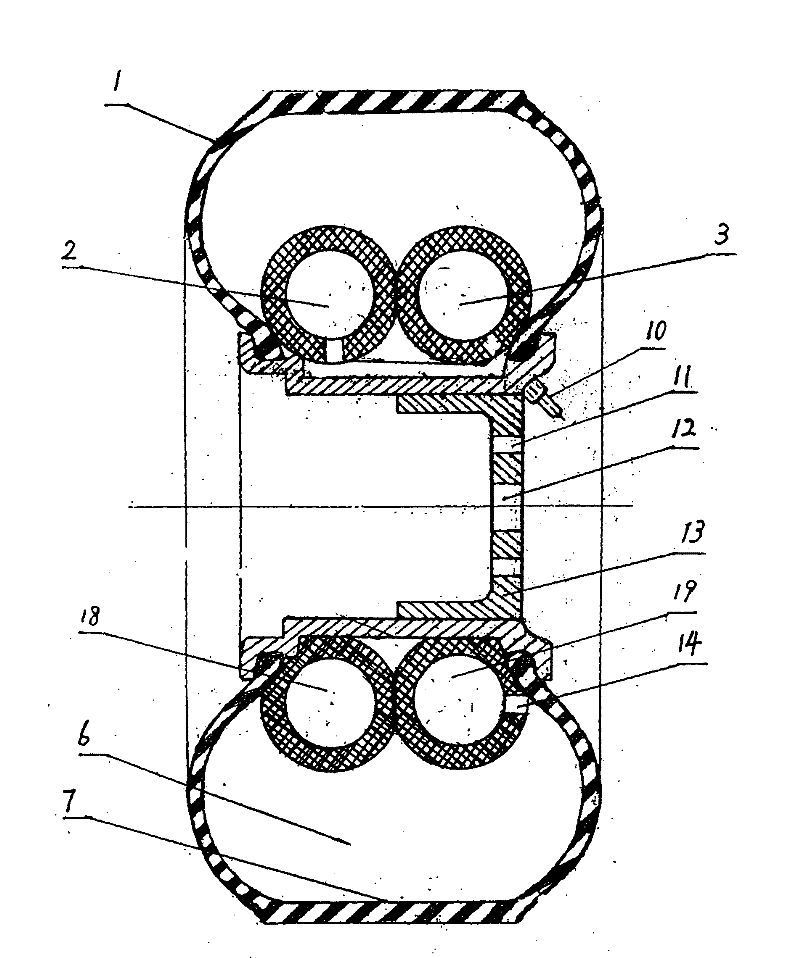

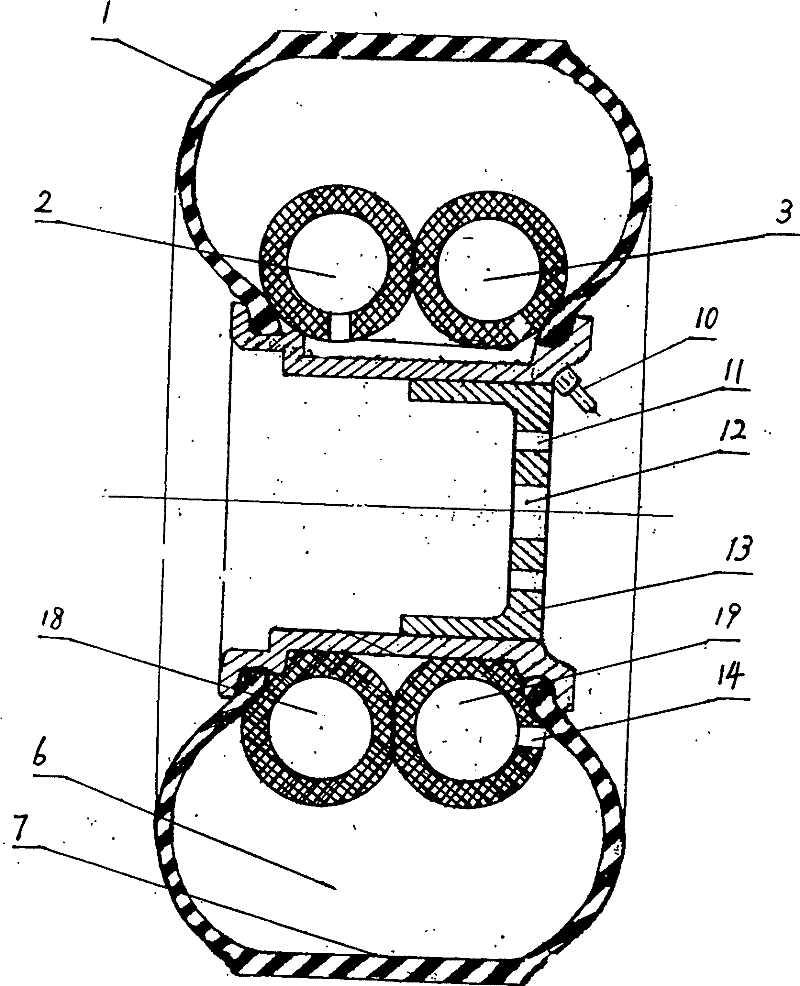

[0009] Example 1: from figure 1 , figure 2 , it can be seen that the present invention is composed of cover tire 1 and many inner tubes combined tires 2,3, wheels 13, valve 10, and a plurality of inner tubes 2,3 are set on the wheels 13, and a plurality of inner tubes 2,3 are provided with valve holes 8,9, valves 10. One side of the inner tube 3 is provided with a single valve 14, and the inner tube 3 is inflated by the valve 10 and enters the inner tube 2, 3 inner tube cavities 18, 19 through the air intake pipe 17, the air intake hole 8, and the inner tube cavity 19. Air pressure can enter cover tire cavity 6 by valve 14, and inner tube of a tube 2,3 diameters are greater than wheel and less than cover tire diameter, cover tire 1 is sleeved on the wheel 13, forms an inflation cavity 6 between cover tire inner surface 7 and inner tube of a tube 2,3.

Embodiment 2

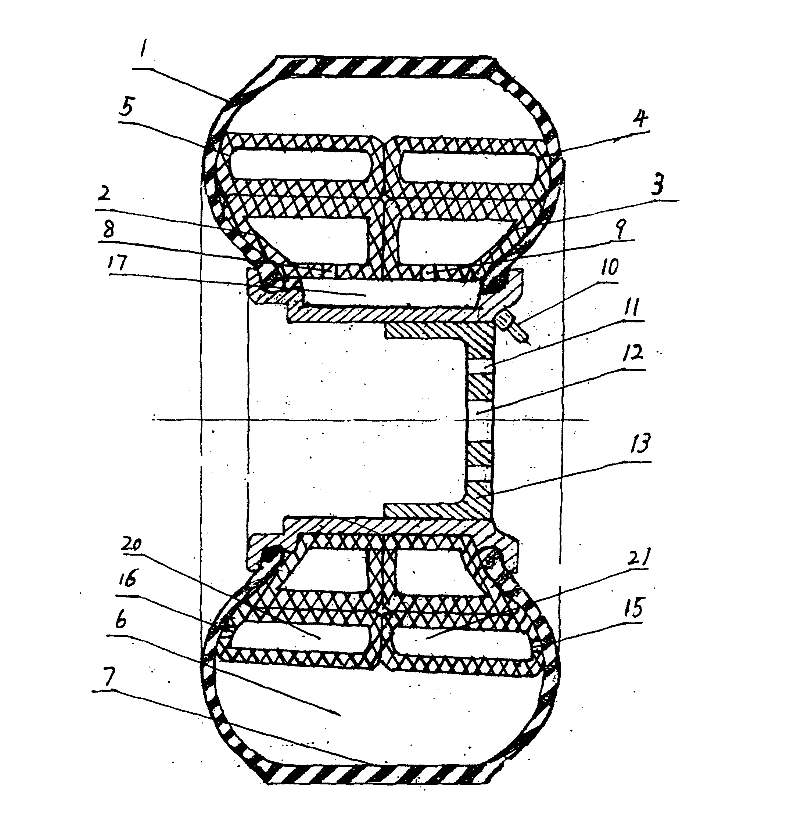

[0010] Example 2: From figure 2 . Visible multi-inner tube combination tire 2,3 top also is suitably equipped with inner tube 4,5, inner tube 3 one side is provided with single valve 14, is inflated by valve 10 and enters inner tube 2, air intake 8, air intake 9 holes 3 inner tube cavity 18,19, inner tube cavity 19 air pressure can enter cover tire cavity 6 by valve 14, and the air pressure in cover tire cavity 6 enters inner tube of a tube 4,5 inner tube cavity 20,21 by valve inlet valve 15,16. Inner tire 2,3,4,5 diameter is greater than wheel and is less than cover tire diameter, and cover tire 1 is sleeved on the wheel 13, forms an inflation cavity 6 between cover tire inner surface 7 and many inner tube combination tires 2.

Embodiment 3

[0011] Example 3: from figure 1 , figure 2 , the visible multi-inner tube combination tire can have a plurality of inner tuber combinations, can suit a plurality of inner tubers at wheel 13, and multiple inner tuber diameters are greater than wheel and less than cover tire diameter.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap