Built-in dimming motor device of automobile headlamp

A technology for automobile headlights and dimming motors, which is applied to signal devices, optical signals, vehicle components, etc., can solve problems such as increased use costs, motor damage, and overweight, etc., and achieves good self-locking performance, large driving torque, and reduced cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

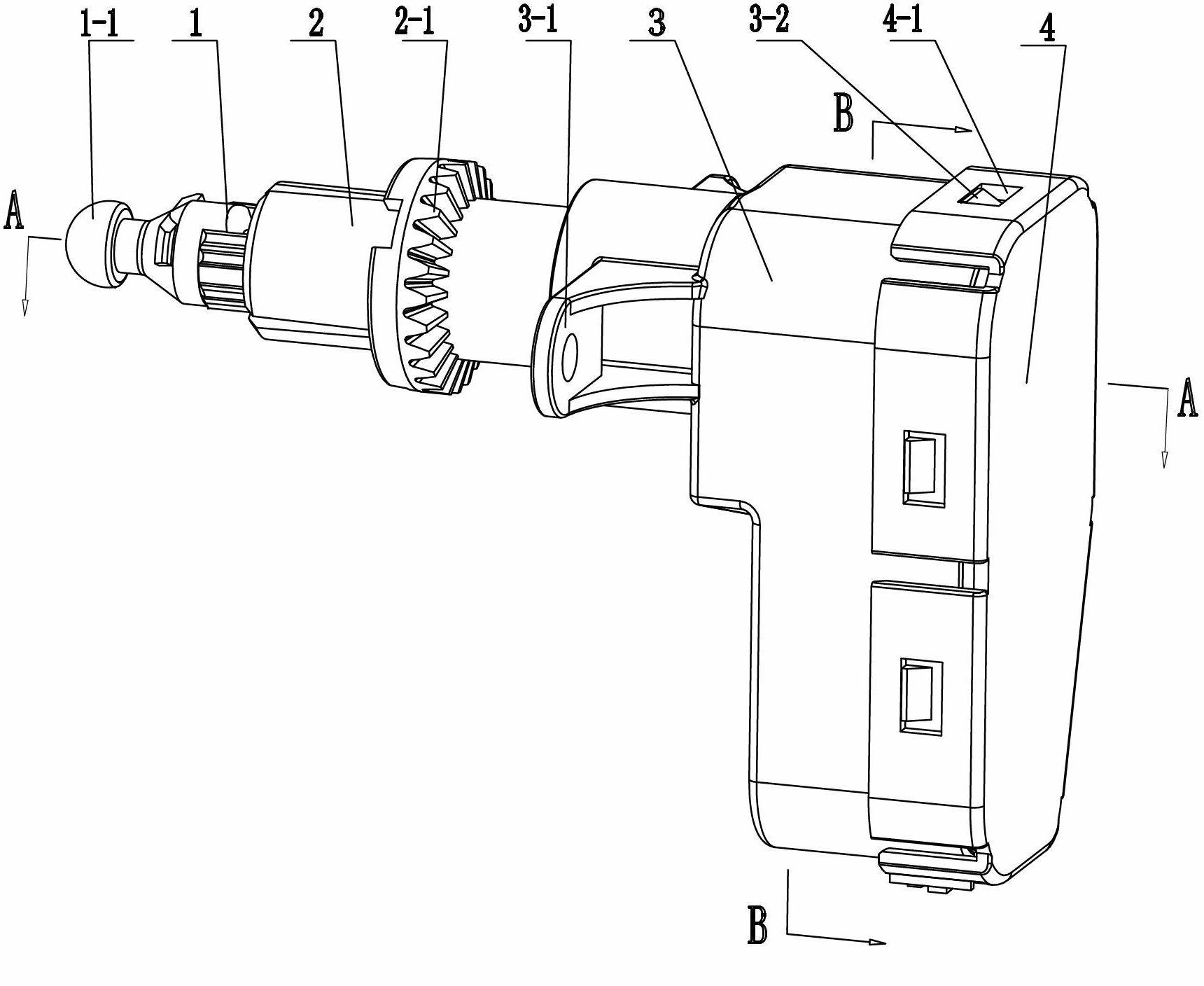

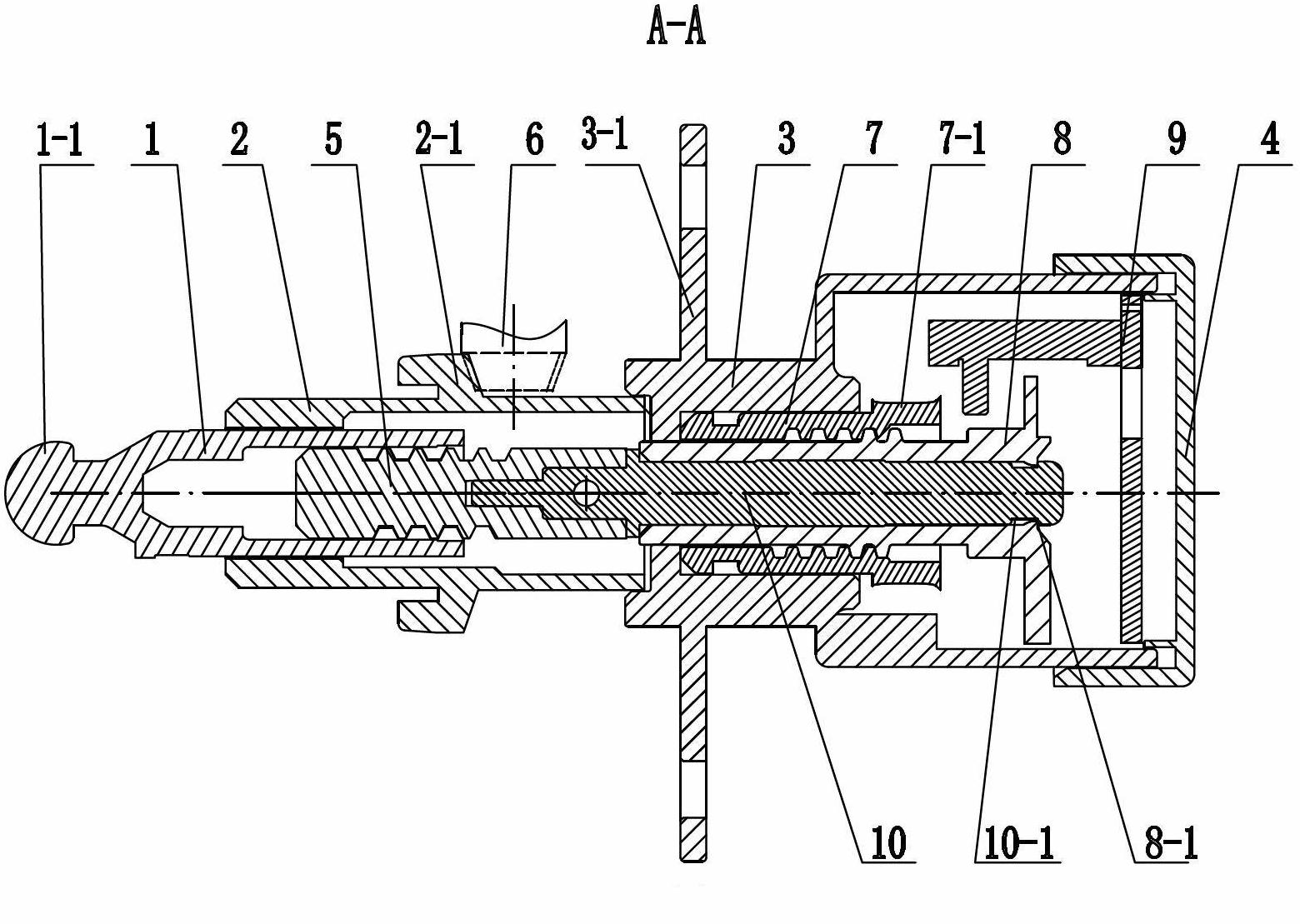

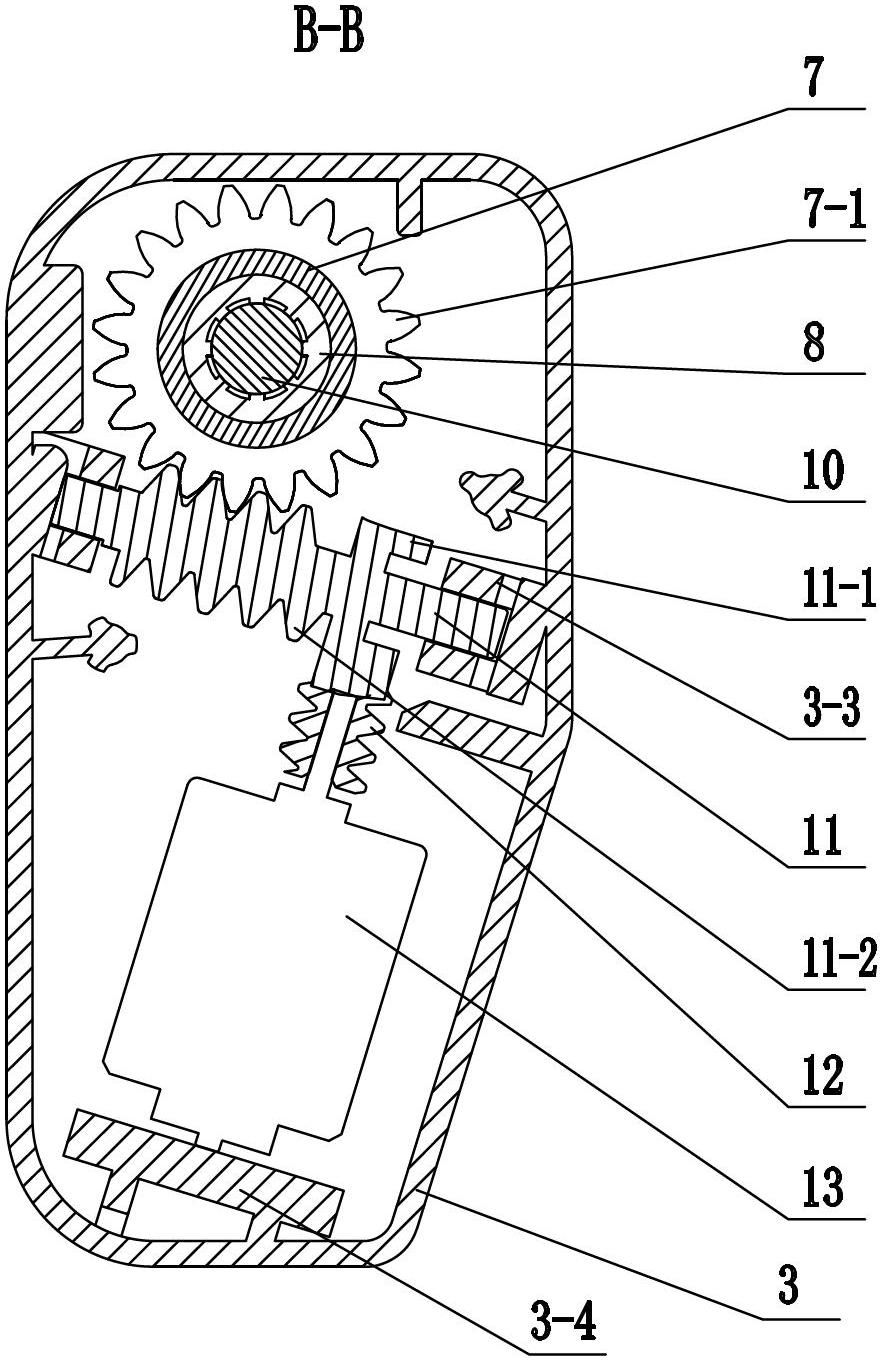

[0014] See Figure 1-4 As shown, the automotive headlamp built-in dimming motor device of the present invention includes a housing 3, a rear cover 4, an adjustment mechanism, a motor drive mechanism, a manual adjustment sleeve 2 and a circuit board 9.

[0015] See Figure 1-4 As shown, the adjustment mechanism of the present invention includes a ball stud 1, a threaded shaft 5, a connecting shaft 10 and an axle sleeve 8, and the inner hole of the ball stud 1 having a ball head 1-1 on the outside is connected to the threaded shaft 5 through a thread, and the thread The shaft 5 is connected to the connecting shaft 10. The ball head 1-1 of the ball head rod 1 is placed on the inner side of the reflector of the lamp. Through the axial movement of the ball head rod 1, the reflective surface of the headlight is driven to move, and the height of the focal length of the reflected light is adjusted. , so as to achieve the effect of adjusting the headlights. See Figure 1-4 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com