Poly urethane (PU) or thermal receiver unit (TPU) film with anti-drag micro-groove structure for airship skin

A micro-groove and skin technology, applied in the field of airship skin materials, can solve the problems of poor weather resistance, poor heat insulation, large resistance, etc., and achieve the effects of prolonging the airtime, good shape retention, and small elastic recovery changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

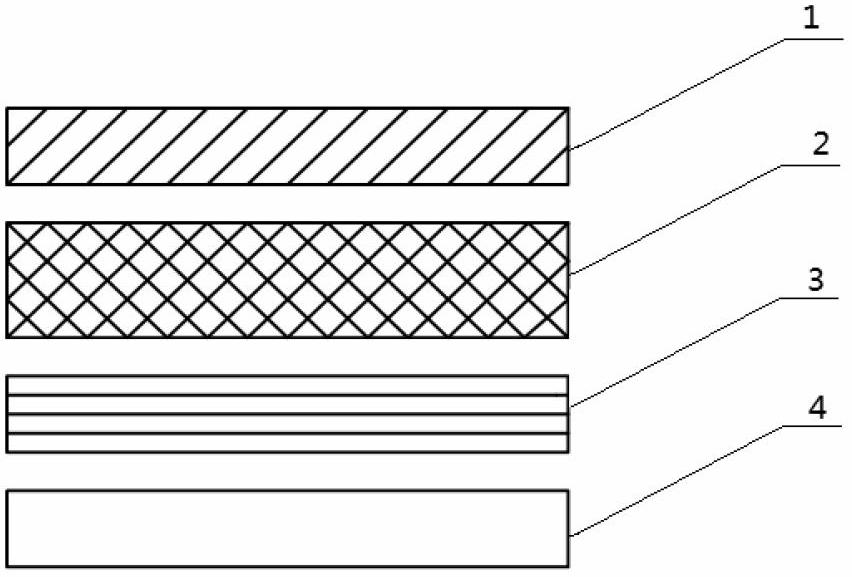

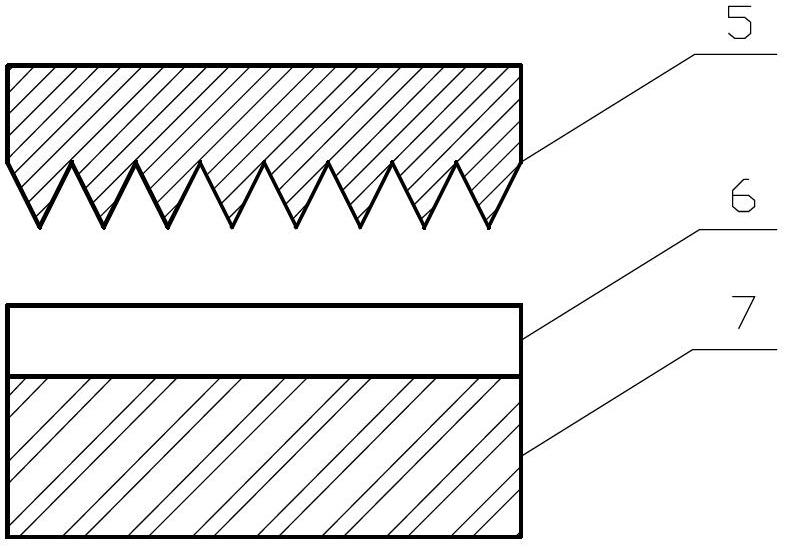

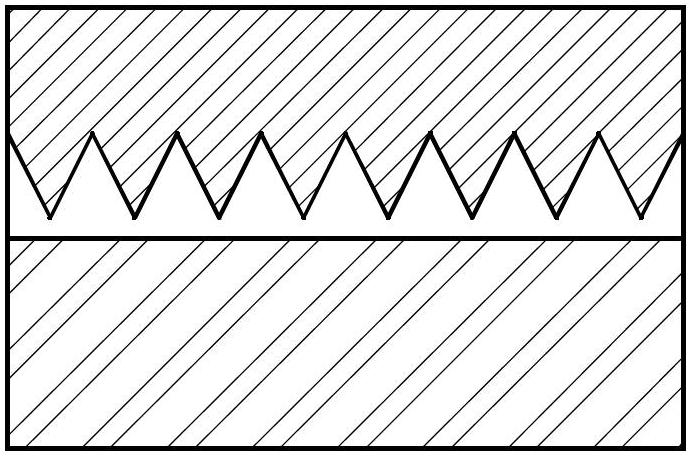

[0075] Specific Embodiment 1: In this embodiment, the PU or TPU film with a drag-reducing micro-groove structure for the airship skin includes a "V"-shaped groove arranged on the surface, and the "V"-shaped groove is formed on the PU or TPU film. Alternate and transparent grooves are formed on the surface, the width s of each groove is 20-200 μm, and the depth h is 20-200 μm.

[0076] This embodiment provides a PU or TPU film with a drag-reducing micro-groove structure for airship skins. The micro-grooves are prepared by a hot embossing method. The hot embossing mechanism analysis of the film material in this embodiment is as follows:

[0077] Thermal embossing of film materials is based on thermal flow molding of polymers to achieve graphic replication. When the size of the template pattern is small and the periodicity is strong, the polymer is easy to transfer completely, and the template pattern can be well replicated on the polymer substrate; when the size of the template ...

specific Embodiment approach 2

[0083] Embodiment 2: This embodiment is different from Embodiment 1 today in that: the thickness of the PU or TPU film is 25-250 μm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0084] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the width s of each groove is 90-110 μm, and the depth h is 90-110 μm. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com