Self-extension graphene and preparation method thereof

A graphene and sulfonated graphene technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems that have not been reported, easy to wrinkle, easy to form stacked structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

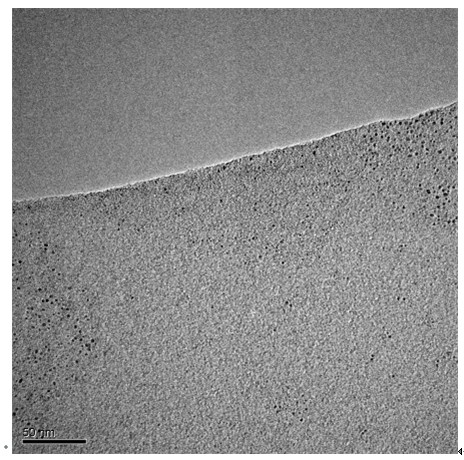

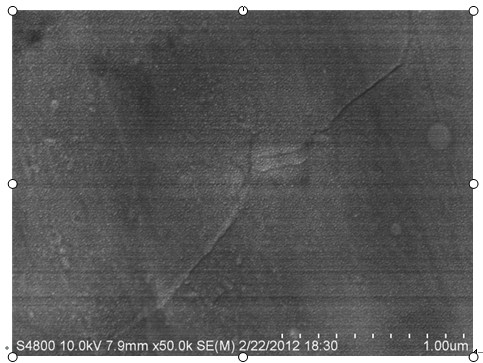

[0021] Example 1: In parts by mass, add 2 parts of flake graphite and 1 part of sodium nitrate into a reactor filled with 50 parts of concentrated sulfuric acid (98%), place the mixed system under an ice-water bath, stir rapidly to make the mixture uniform, and distribute Add 10 parts of potassium permanganate at a time to control the temperature of the system below 20 °C, then raise the temperature of the system to 30 °C, keep stirring at a constant speed for 3 hours, dilute with 150 parts of deionized water, and then add 10 parts of concentration 30wt% hydrogen peroxide solution, and then filtered through a nylon filter membrane with a pore size of 220 nm, and repeatedly washed 3 times with 1 mol / liter hydrochloric acid, and redispersed the filter cake in 150 parts of deionized water, at 4000 rpm Centrifuge at a rotating speed of 20 minutes, and finally dry the obtained liquid part for 24 hours to obtain graphene oxide; in parts by mass, 1 part of graphene oxide is added to...

Embodiment 2

[0022] Example 2: In parts by mass, add 5 parts of flake graphite and 3 parts of sodium nitrate into a reactor containing 150 parts of concentrated sulfuric acid (98%), place the mixed system under an ice-water bath, stir rapidly to make the mixture uniform, and divide Add 30 parts of potassium permanganate to control the temperature of the system below 20 °C, then raise the temperature of the system to 35 °C, keep stirring at a constant speed for 4 hours and dilute with 300 parts of deionized water, then add 30 parts of concentration 30wt % hydrogen peroxide solution, and then filtered through a nylon filter membrane with a pore size of 220 nm, and washed 3 times with 1 mol / L hydrochloric acid, and redispersed the filter cake in 400 parts of deionized water at a speed of 4000 rpm Centrifuge for 25 minutes, and finally dry the obtained liquid part for 40 hours to obtain graphene oxide; in parts by mass, add 1 part of graphene oxide to a reactor containing 1000 parts of deioni...

Embodiment 3

[0023] Example 3: In parts by mass, add 9 parts of flake graphite and 6 parts of sodium nitrate into a reactor filled with 300 parts of concentrated sulfuric acid (98%), place the mixed system under an ice-water bath, stir quickly to make the mixture uniform, and divide Add 60 parts of potassium permanganate to control the temperature of the system below 20°C, then raise the temperature of the system to 40°C, keep stirring at a constant speed for 5 hours and dilute with 500 parts of deionized water, then add 60 parts of 30wt % hydrogen peroxide solution, and then filtered through a nylon filter membrane with a pore size of 220 nm, and washed 3 times with 1 mol / L hydrochloric acid, and redispersed the filter cake in 700 parts of deionized water at a speed of 4000 rpm Centrifuge for 30 minutes, and finally dry the obtained liquid part for 48 hours to obtain graphene oxide; in parts by mass, 1 part of graphene oxide is added to a reactor containing 1600 parts of deionized water,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap