Automatic slag scraping and oil collecting slag, oil, sludge and sewage four-phase separation equipment

A phase separation and automatic technology, applied in filtration separation, liquid separation, separation methods, etc., can solve the problems of many intermediate links, long residence time, and increased sewage treatment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

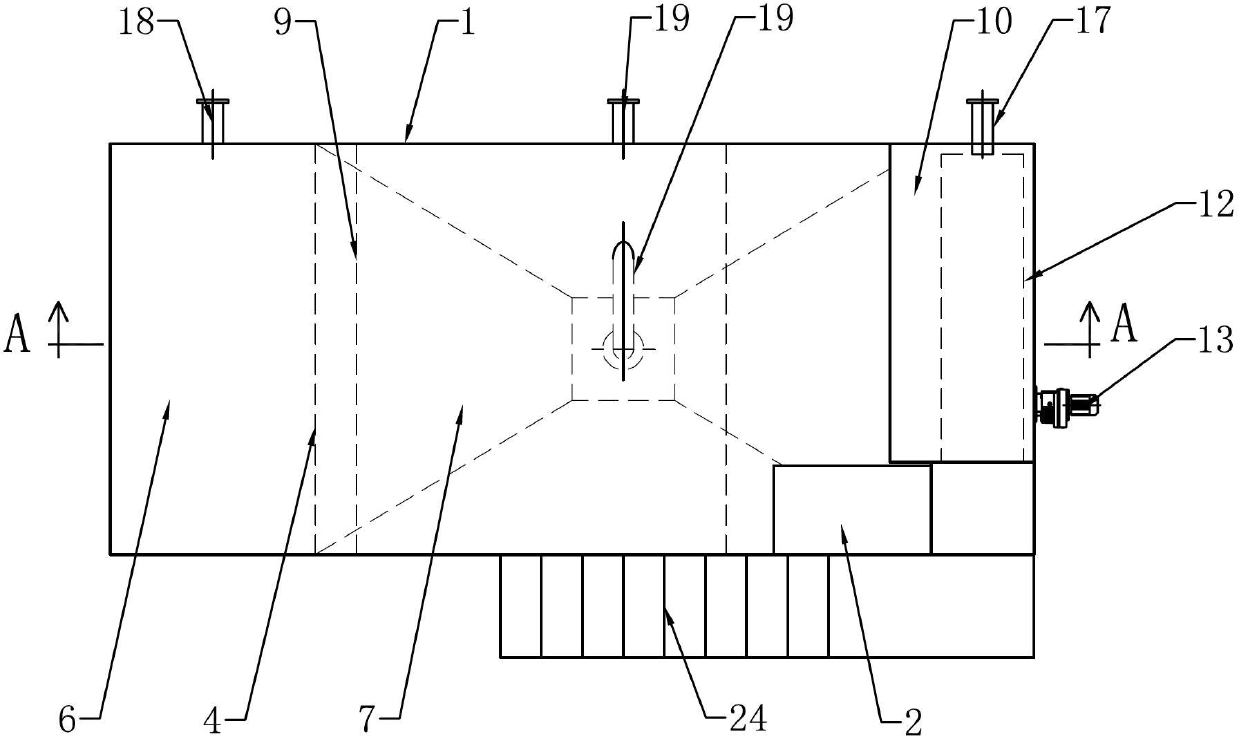

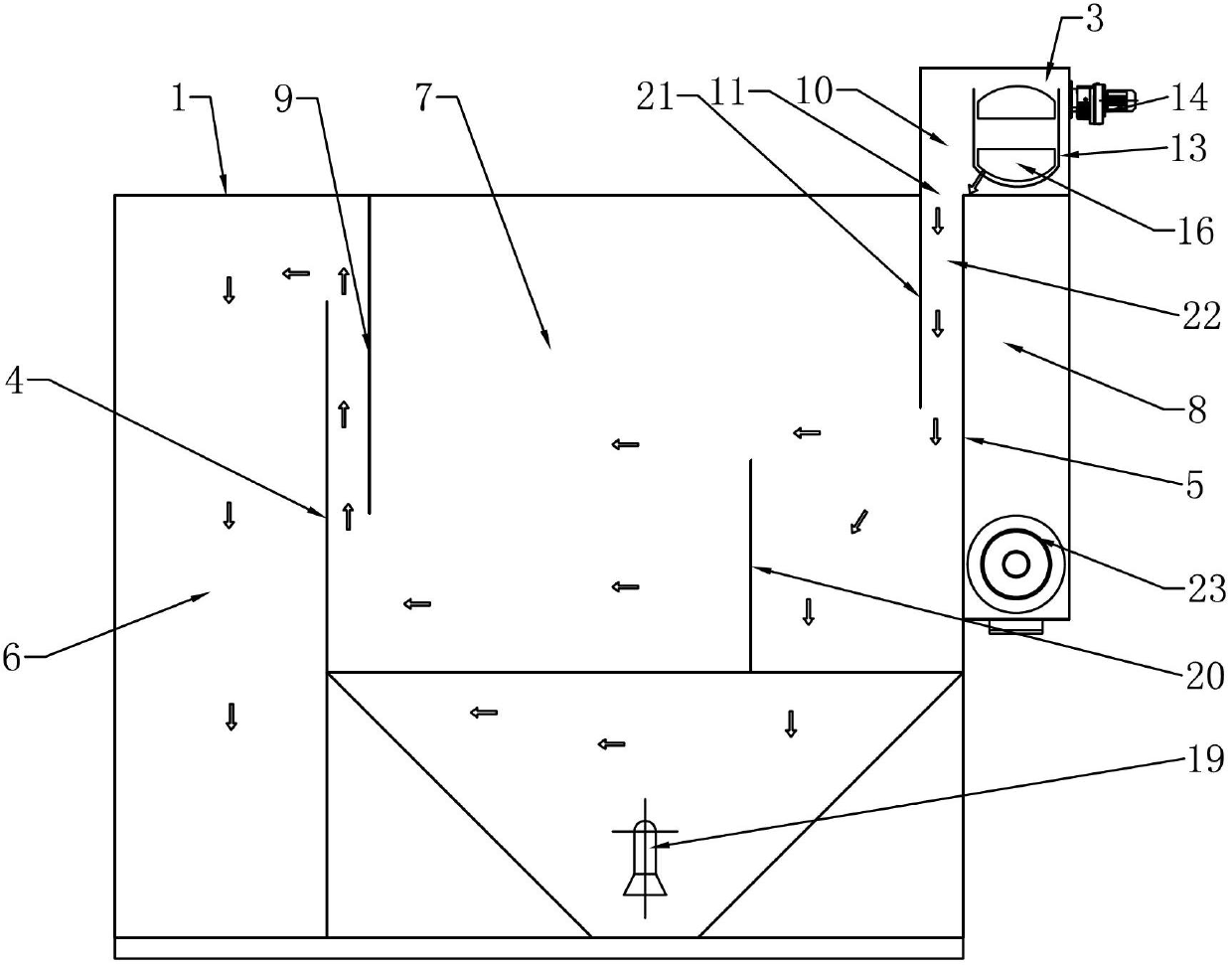

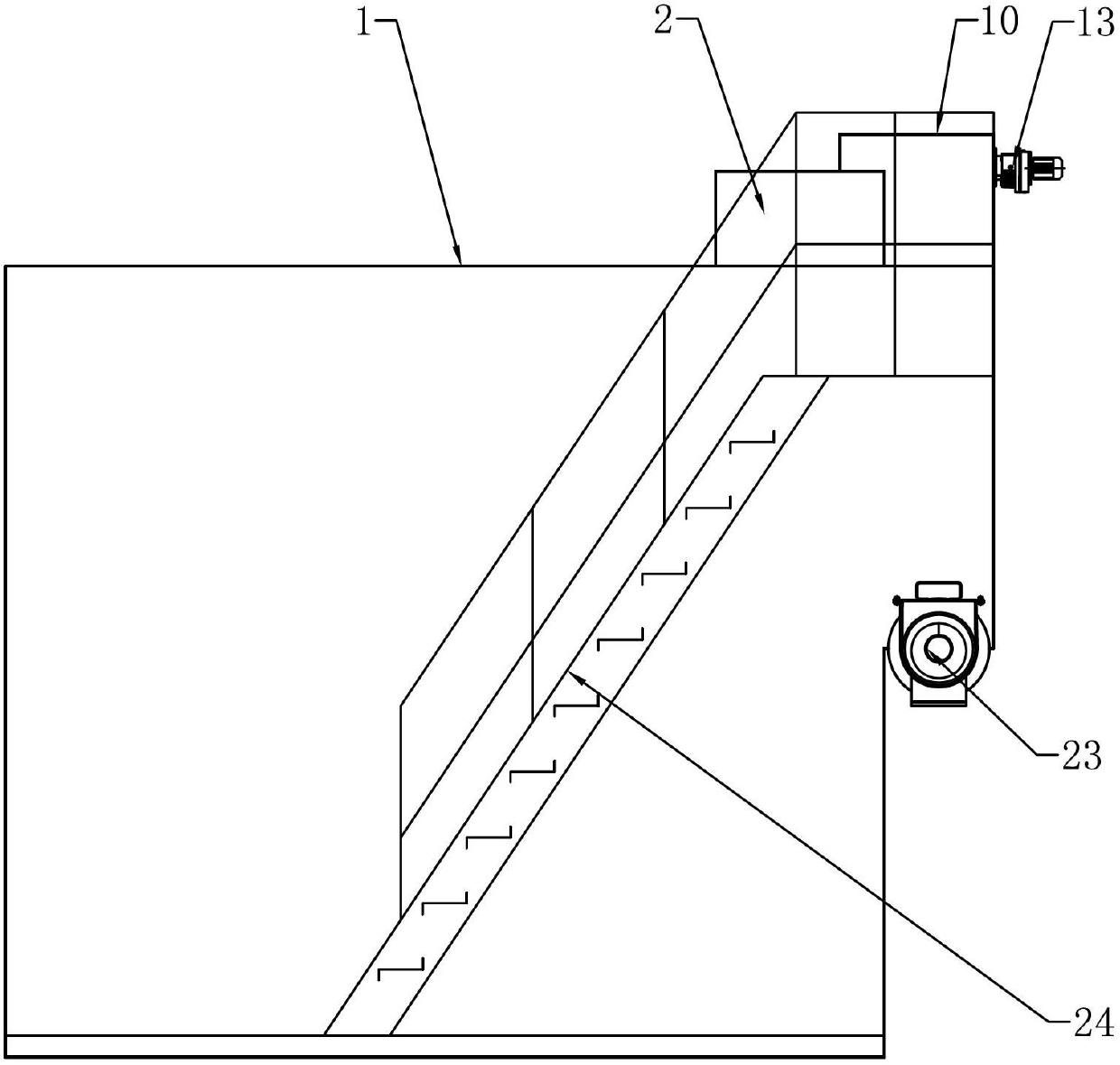

[0017] like figure 1 , figure 2 As shown, the automatic residue scraping and oil collection type residue oil sludge water four-phase separation equipment of the present invention includes a casing 1, an oil skimmer 2 and an automatic scraping device 3, and the casing 1 is sequentially provided with first and second Partition plates 4 and 5, the first and second partition plates 4 and 5 divide the shell 1 into an intermediate tank 6, an oil separation sedimentation tank 7 and a slag storage tank 8, an intermediate tank 6, an oil separation sedimentation tank 7 and a slag storage tank 8 are arranged sequentially from left to right, and the lower part of the oil separation sedimentation tank 7 adopts an inverted trapezoidal structure with a large upper end and a smaller lower end. The front, rear and lower end surfaces of the first partition plate 4 are all welded on the housing 1, and there is a gap between the upper end of the first partition plate 4 and the housing 1, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com