A kind of washing process of papermaking pulp modified into viscose fiber pulp

A viscose fiber and pulp making technology, applied in the direction of washing/replacing pulp treatment liquid, etc., can solve the problem that the hemicellulose and ash content of the washed pulp are not considered, and it is not applicable and cannot effectively remove the hemicellulose and ash. and other problems, to achieve the effect of excellent penetration performance, high cleaning degree and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

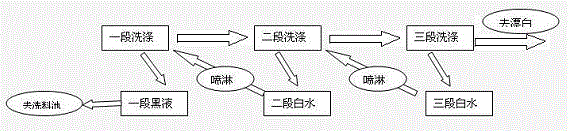

[0048] A washing process for denaturation of papermaking pulp into viscose pulp, using a multi-stage countercurrent washing process, and adding a washing aid Busperse2858 during the washing process, the process is as follows:

[0049] A. Add black liquor to the coarse pulp from cooking to reduce the concentration of high-concentration pulp to 2.0%, then add detergent additive Busperse2858, the dosage is 0.5 kg / ton pulp, mix for 20 minutes, and pump out by pulp pump , into the stage I pulp washer;

[0050] B. Spray and wash the black liquor provided by the black liquor tank in the second section, and the washed black liquor enters the black liquor tank in the first section, and the black liquor temperature in the black liquor tank in the first section is 75°C;

[0051] C Then the pulp enters the pulp washing machine in the second stage, and the washing of the black liquor tank in the third stage is sprayed and washed with white water, and the washing liquid after washing enters...

Embodiment 2

[0081] A washing process for denaturation of papermaking pulp into viscose pulp, using a multi-stage countercurrent washing process, and adding a washing aid Busperse2858 during the washing process, the process is as follows:

[0082] A. Add black liquor to the coarse pulp from cooking to reduce the concentration of high-concentration pulp to 2.4%, then add detergent additive Busperse2858, the dosage is 1.2 kg / ton pulp, mix for 10 minutes, and pump out by pulp pump , into the stage I pulp washer;

[0083] B. Spray and wash the black liquor provided by the black liquor tank in the second section, and the washed black liquor enters the black liquor tank in the first section, and the black liquor temperature in the black liquor tank in the first section is 75°C;

[0084] C Then the pulp enters the pulp washing machine in the second stage, and the washing of the black liquor tank in the third stage is sprayed and washed with white water, and the washing liquid after washing enters...

Embodiment 3

[0114] A washing process for denaturation of papermaking pulp into viscose pulp, using a multi-stage countercurrent washing process, and adding a washing aid Busperse2858 during the washing process, the process is as follows:

[0115] A. Add black liquor to the coarse pulp from cooking to reduce the concentration of high-concentration pulp to 2.5%, then add detergent additive Busperse2858, the dosage is 1 kg / ton pulp, mix for 30 minutes, and pump out by pulp pump , into the stage I pulp washer;

[0116] B. Spray and wash the black liquor provided by the black liquor tank in the second section, and the washed black liquor enters the black liquor tank in the first section, and the black liquor temperature in the black liquor tank in the first section is 72°C;

[0117] C Then the pulp enters the pulp washing machine in the second stage, and the washing of the black liquor tank in the third stage is sprayed and washed with white water, and the washing liquid after washing enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com