Groove-pipe combined exhaust technology for joint grouting for normal concrete arch dam

A technology of concrete arches and grouting grooves, applied in new technical fields, can solve problems such as blocked irrigation areas, blockage of exhaust systems, and affecting the quality of joint grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The structures not described in detail in the embodiments are the same as the existing known structures.

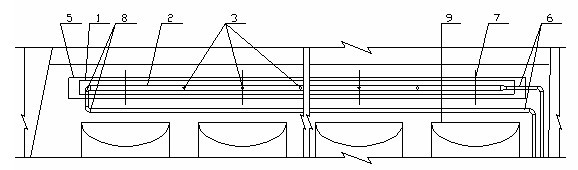

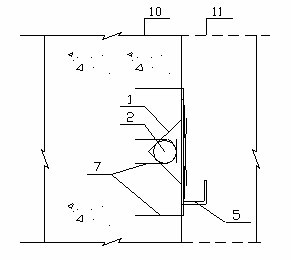

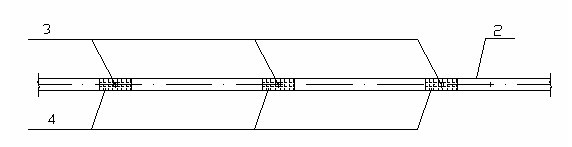

[0021] Such as figure 1 , figure 2 Shown: The joint grouting of the normal concrete arch dam and the combination of groove and pipe exhaust technology The groove and pipe combined exhaust system consists of exhaust groove 1, exhaust main pipe 2, exhaust hole 3, hole sealing kraft paper 4, and exhaust pipe 6 , Sealing tank composed of 5 galvanized iron sheets. The grooved pipe combined with the exhaust system is to form a triangular exhaust groove 1 on the top of the irrigation area on the side of the first poured block 10 when the concrete is poured first, and the exhaust main pipe 2 is made with vent holes 3 and sealed with kraft paper 4. After the hole is installed in the exhaust groove 1, the two ends of the exhaust main pipe 2 are connected to the exhaust pipe 6 through the elbow 8, and the groove-sealing galvanized iron sheet 5 is installed to seal the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com