Columnar combustion arm guardrail

A guardrail and column type technology, which is applied to drilling equipment, earthwork drilling, support devices, etc., can solve the problems of insecurity, time-consuming and laborious, insertion, etc., and achieve the effect of reducing labor intensity, simple retracting and unloading operations, and protecting the guardrail.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

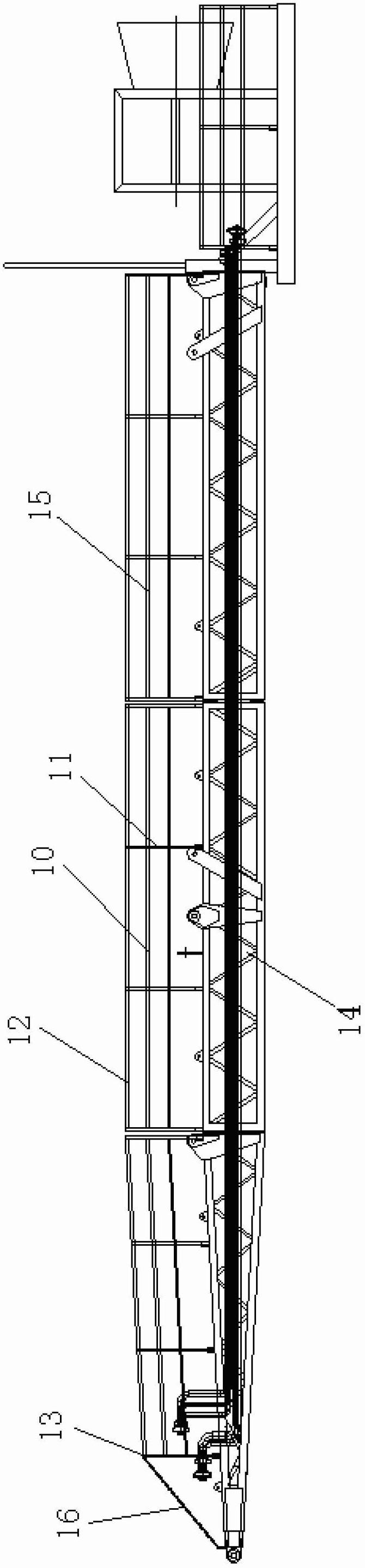

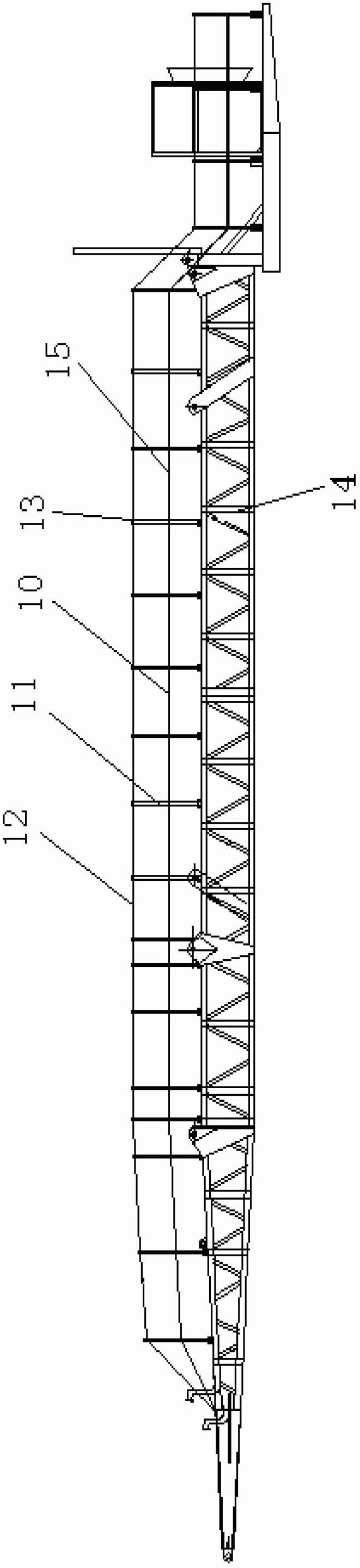

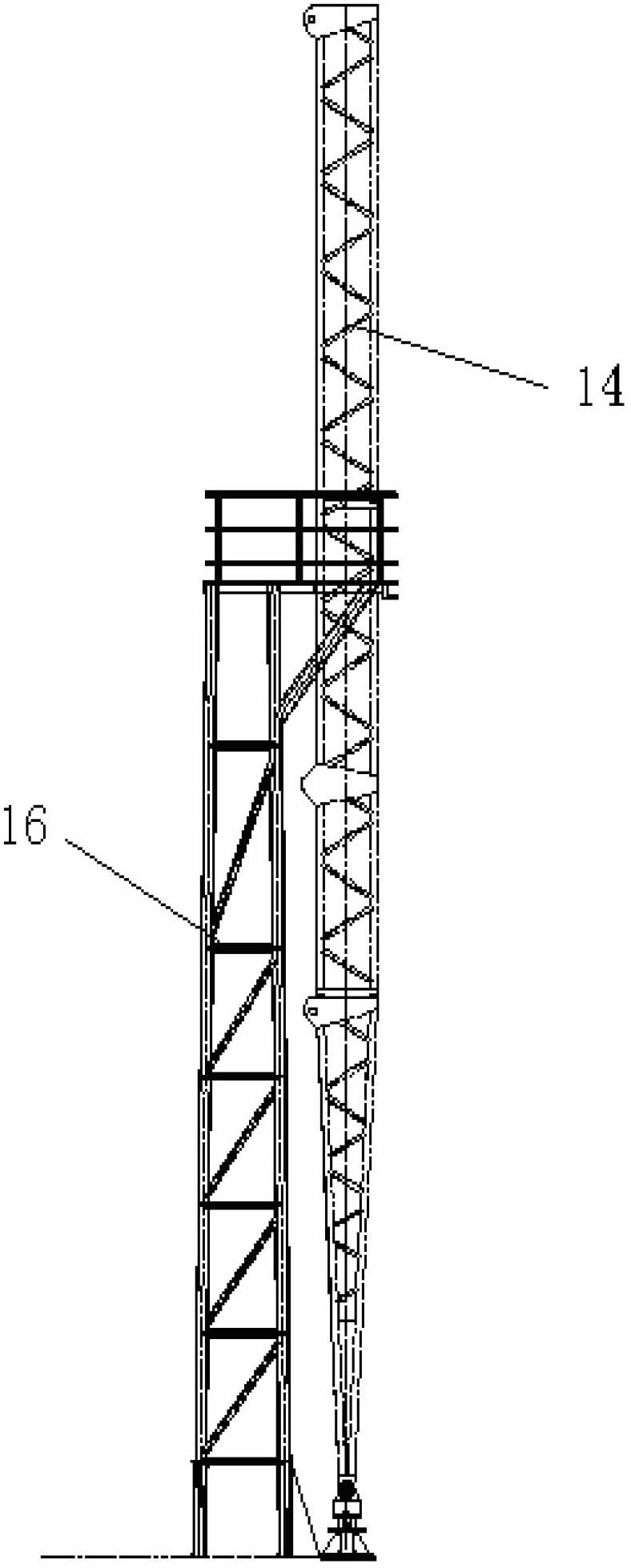

[0022] Such as Figure 5 , Figure 6 As shown, the present invention includes a plurality of cross bars 21 arranged on both sides of the combustion arm 20, and a connection block 22 is respectively arranged at both ends of each cross bar 21, and the connection blocks 22 on two adjacent cross bars 21 pass through a pin 23, and then form an integral beam 24;

[0023] A plurality of connecting plates 25 are arranged at intervals at the bottom of the beam 24, each connecting plate 25 is connected to a vertical rod 26 through a pin shaft 23, and the bottom of each vertical rod 26 is connected to a connecting plate provided on the combustion arm 20 through a pin shaft 23 27. An upper through hole 28 and a lower through hole 29 are provided at intervals in the middle of each vertical pole 26;

[0024] A fixed plate 30 is arranged horizontally at the root ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com