Floating lighthouse type natural-vibration-frequency-adjustable wave-energy directly-driven power generation device

A technology of natural vibration frequency and power generation device, which is applied to ocean energy power generation, engine components, machines/engines, etc., to achieve the effects of simple structure, high practicability, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

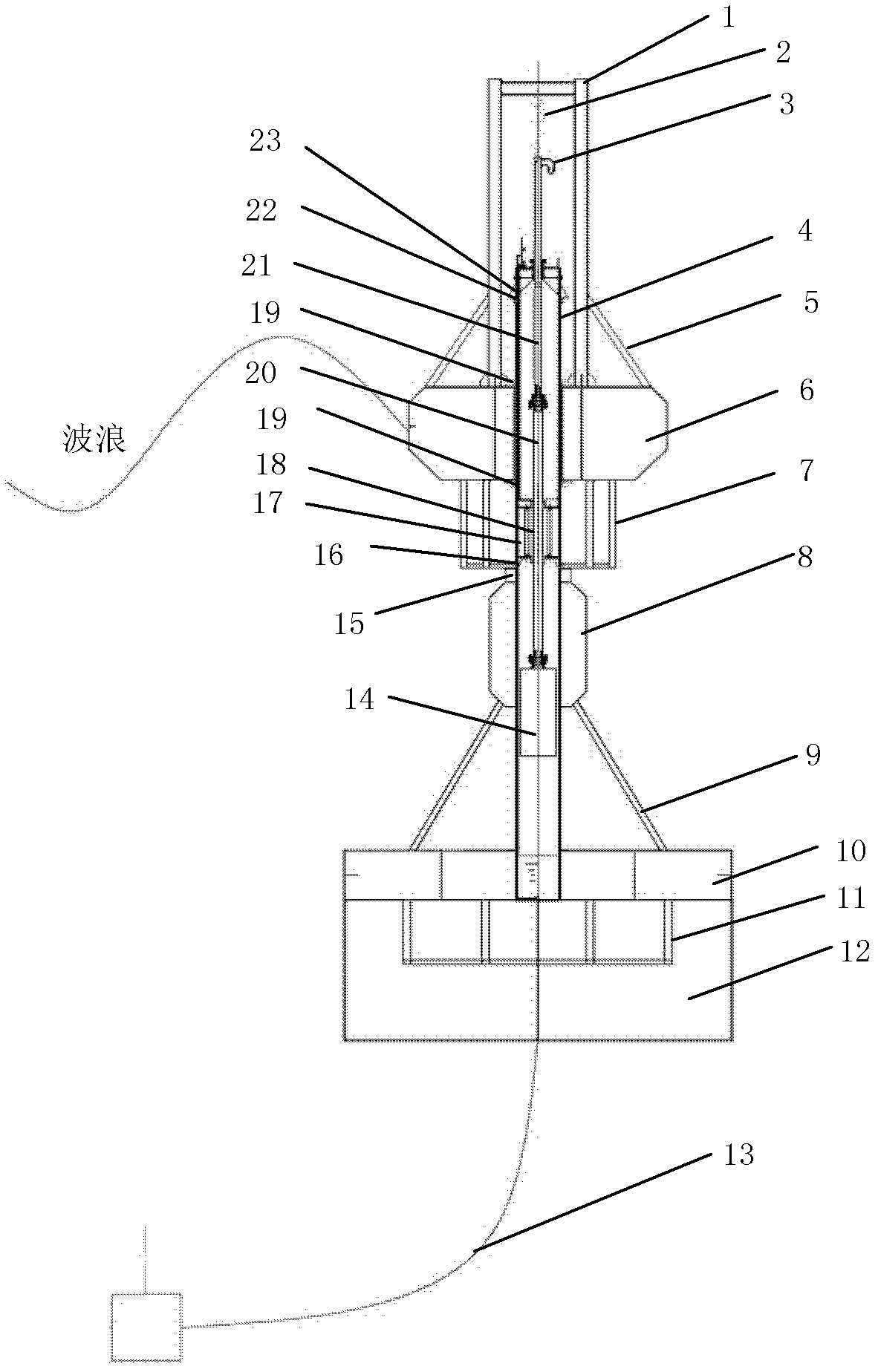

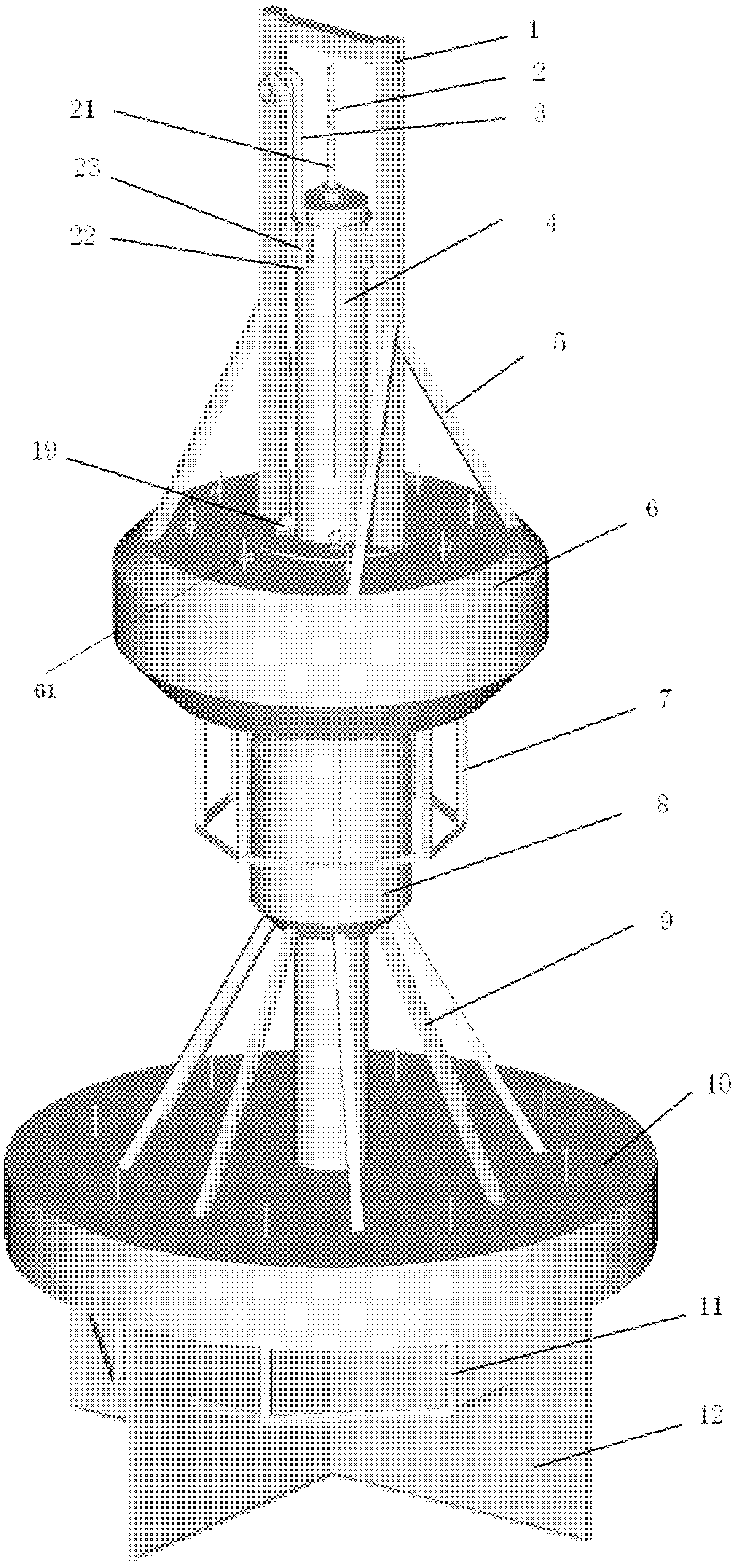

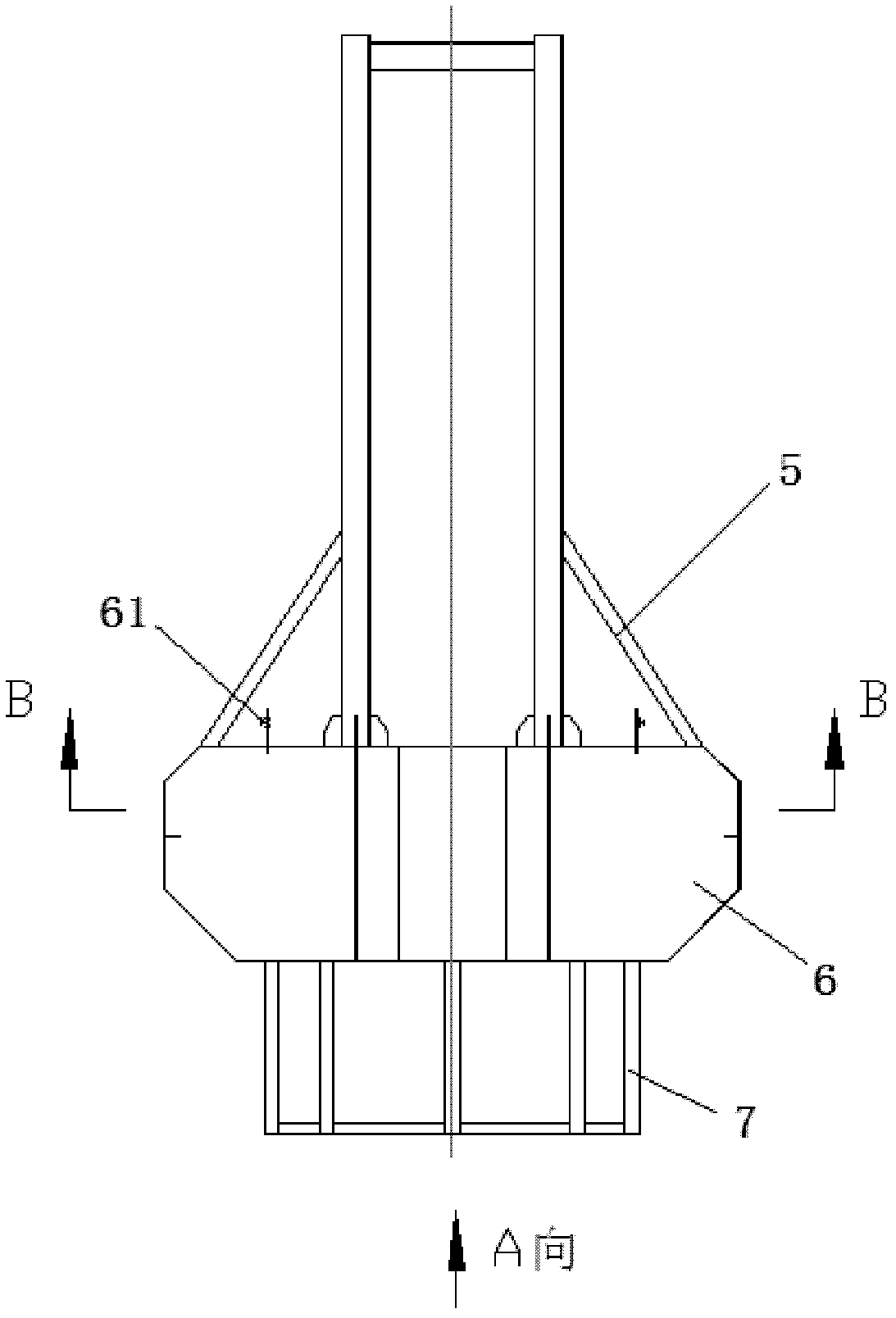

[0033] see Figure 1 to Figure 7 As shown, a floating lighthouse-type wave energy direct drive power generation device with adjustable natural frequency, including: gantry 1, oscillating float 6, flexible connector 2, straight tube 4, two support points at the lower end of gantry 1 are connected On the oscillating float 6, its gantry is connected to the upper end of the flexible connector 2, the lower end of the flexible connector 2 is connected to the upper end of the connecting shaft 21, and the lower end of the connecting shaft 21 is connected to the upper end of the generator rotor 20; the oscillating float 6 is movably sleeved on the straight tube 4 peripheral, a horizontal damping tube 10 is rigidly connected to the lower end of the straight tube 4, and a horizontal damping tube water pipe 11 is connected below the horizontal damping tube 10; the straight tube 4 is equipped with a generator stator 18 and a gravity recovery hammer 14, and the gravity recovery hammer 14 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com