Magnetic particle flow power generation system having no rotary movement

A power generation system and rotary motion technology, applied in electrical components, electromechanical devices, etc., can solve problems such as movement form restrictions, and achieve the effect of reducing manufacturing difficulty, simple structure, flexible structure and layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

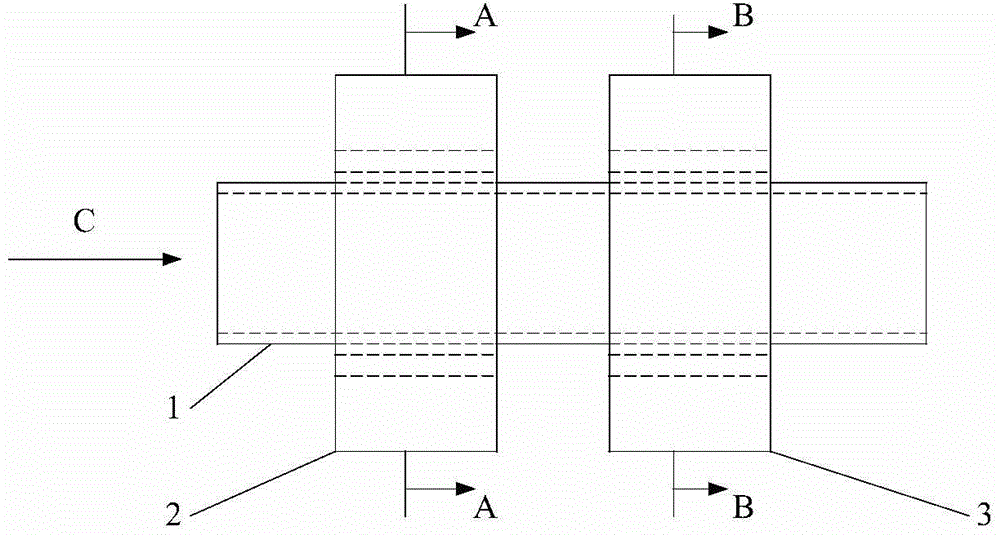

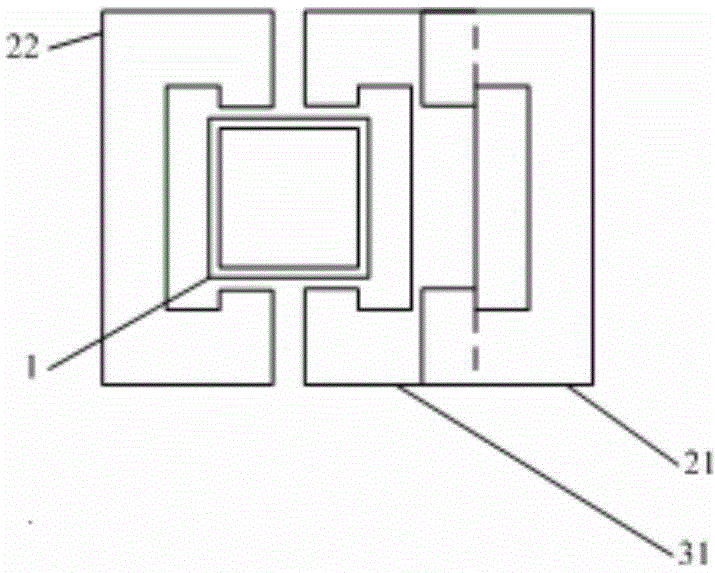

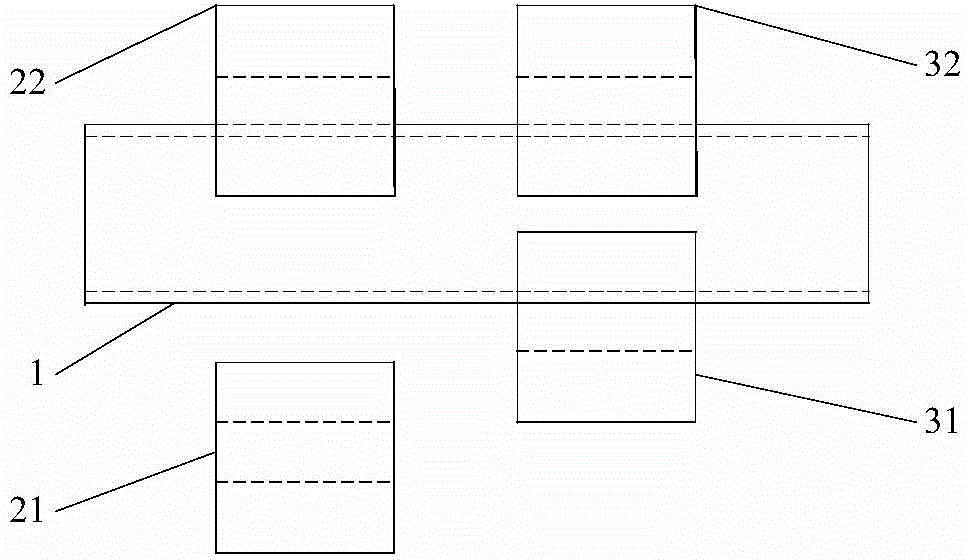

[0027] The invention relates to a magnetic particle flow power generation system without rotating motion. The system adopts a direct coupling method of a prime mover and a magnetic particle flow power generation system to generate electricity, eliminating the need for rotating parts such as turbines. The prime mover can be a gas engine, a steam engine or a diesel engine. Take a gas engine as an example. The structure of the gas engine is similar to the previous gas engine. The air is compressed by the compressor and enters the combustion chamber of the gas engine to mix and burn with the fuel. The gas expands rapidly when heated. . At this time, the magnetic particles of the present invention are sprayed into the combustion chamber, and the magnetic particles are mixed with the gas, driven by the gas to move at a high speed, and carry kinetic energy. A large number of magnetic particles form a flow of magnetic particles and move at a high speed in the conduit. The attraction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com