Oil supply device for horizontal type rotary compressor

A technology of rotary compressors and supply devices, which is applied to components of pumping devices for elastic fluids, rotary piston type/oscillating piston type pump components, mechanical equipment, etc., and can solve left and right swings, up and down vibrations, and lack of oil , It is impossible to completely prevent the problems of lubricating oil in horizontal rotary compressors, and achieve the effects of long service life, low production cost, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

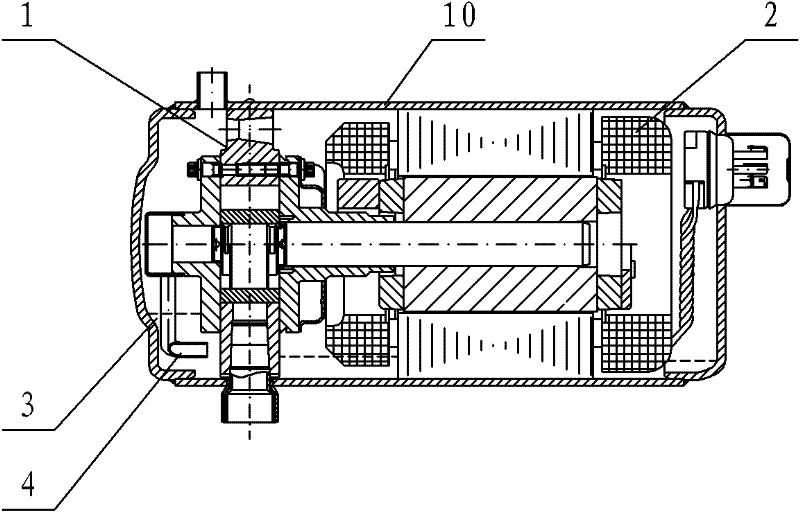

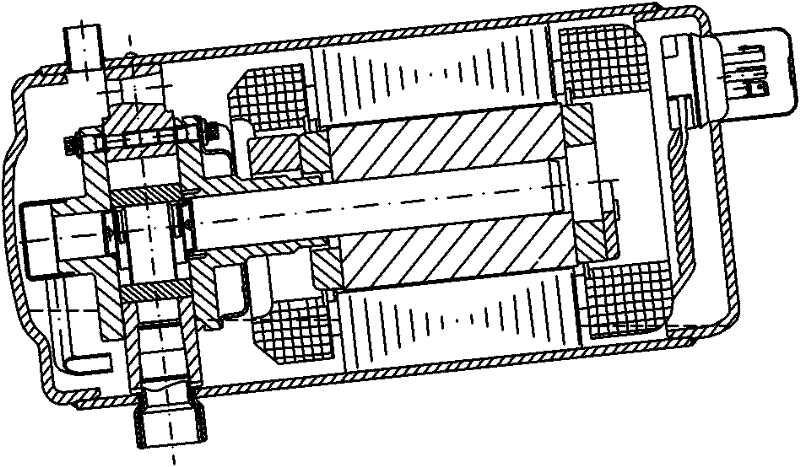

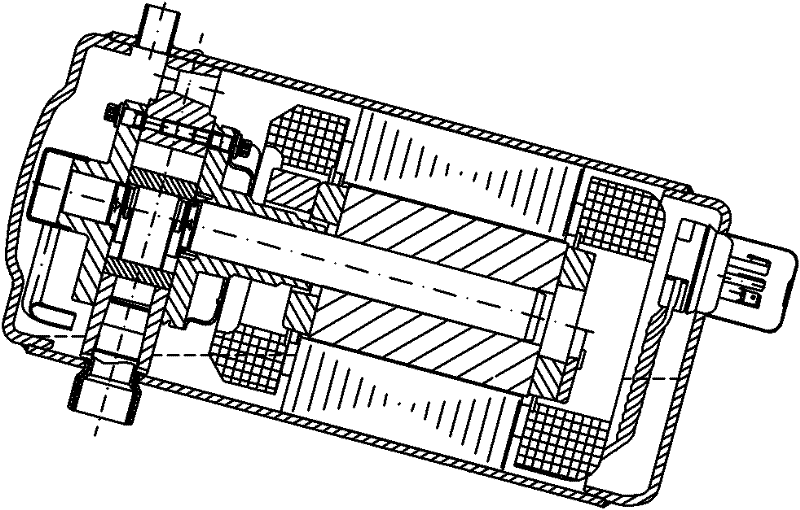

[0023] see Figure 4-Figure 6 , the oil supply device of the horizontal rotary compressor, including the compression part 1, the motor part 2, the oil storage part 3 and the lubricating oil arranged in the housing 10, the compression part 1 and the oil storage part 3 are located in the low pressure area, and the compression part 1. It communicates with the oil storage part 3 through the oil suction channel or the oil suction pipe 4. The motor part 2 is located in the high pressure area, and the low pressure area is connected with the high pressure area. Part 2 of the non-return mechanism. The check mechanism includes a valve block 5 slidably arranged in the valve seat 6. The valve seat 6 is provided with an oil passage hole 6.1 blocked by the valve block 5. The valve block 5 is close to the side of the oil storage part 3, and the oil passage hole 6.1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com