Novel oil leakage preventing sealing structure for automobile hydraulic power steering gear shaft end

A technology of hydraulic power and steering gear, which is applied to the sealing of the engine, fluid steering mechanism, engine components, etc., can solve the leakage of high pressure oil in the power steering gear assembly, affecting the service life and reliability of the car, and the appearance is not clean, etc. problems, to achieve the effect of eliminating oil leakage, improving quality and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

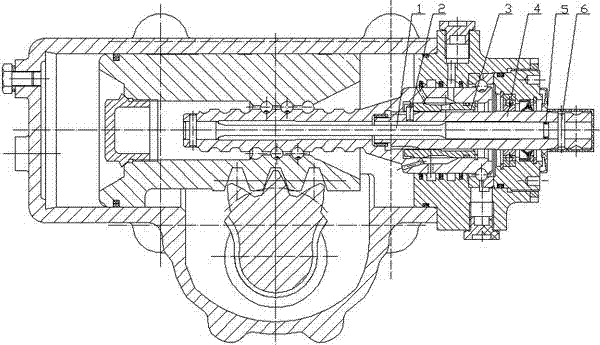

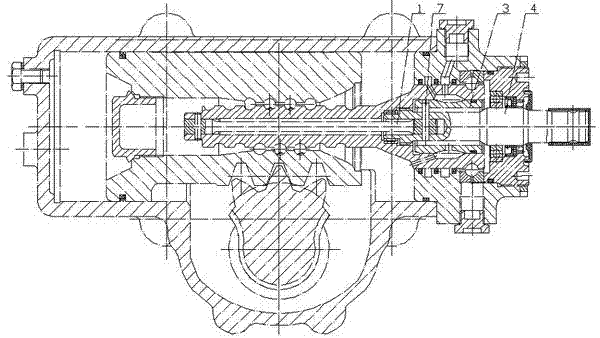

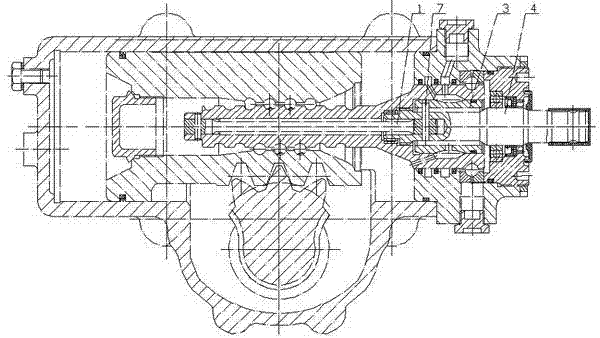

[0009] Figure 3 shows the new structure of the anti-leakage oil seal at the shaft end of the automobile hydraulic power steering gear. The positioning pin 6 for fixing the torsion bar 1 and the input shaft is designed inside the power steering gear, and a positioning pin 7 fixes the valve sleeve 3 and the torque The relative positions of the three parts of rod 1 and input shaft 4 reduce the difficulty brought by multiple positioning between workpieces, reduce the difficulty factor of the process, and cancel the figure 1 The input shaft and the positioning pin 2 of the valve sleeve, the positioning pin 6 and the O-ring 5 of the torsion bar and the input shaft of the original automobile hydraulic power steering gear shaft end anti-leakage sealing structure are truly "one-star pipe" The function of "three" fundamentally solves the phenomenon of slow leakage of high-pressure oil in power steering gears.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com