Center alignment method of large-sized equipment

A technology of large-scale equipment and equipment, which is applied to measuring devices, instruments, and mechanical devices, etc., can solve the problems of complex centering and centering work processes, troubled construction units, and large labor hours, so as to improve the efficiency of alignment work. , The effect of simplifying the equipment alignment process and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

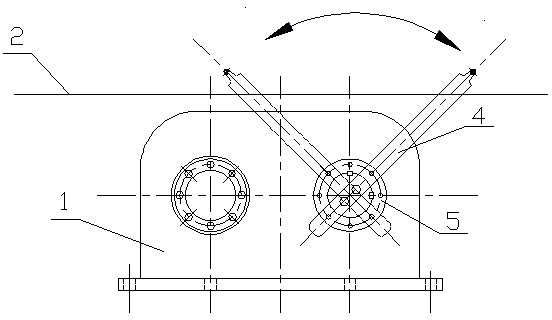

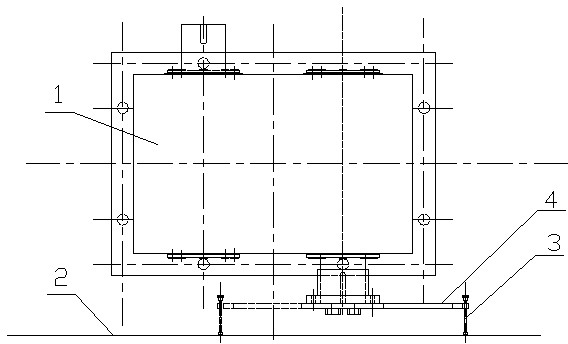

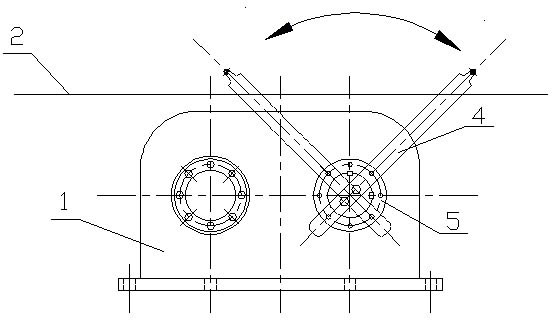

[0009] The invention is easy to operate and simple in process. In large-scale equipment installation and alignment operations, after adjusting the level and elevation of the equipment main body 1, according to the size of the drawing, recheck the size from the coupling 5 to the center of the equipment main body 1, and place the rolled Copy the center line to the top of the coupling 5, and make room for the size of the detection tool, pull the steel wire 2, fix a solid support 4 on the equipment coupling 5, and rotate the coupling 5 so that the swing of the support 4 is the same as The distance between the two points where the steel wire 2 intersects is greater than 1 meter. If necessary, the level of the equipment and the center deviation are detected by hanging a wire drop in the middle of the two points; For the steel wire 2, adjust the reading of the micrometer rod 3, and adjust the horizontal displacement of the equipment 1, so that the readings on both sides of the microme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com