Simple mechanism for detecting and centering arm frame workpiece and detecting and centering method

A technology for centering mechanisms and workpieces, which is applied in the direction of angle/taper measurement, etc., can solve the problems of difficult installation and positioning of crane truss booms, inability to detect workpiece machining allowances, and restrict production progress, so as to facilitate loading and unloading and reduce detection Time, the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

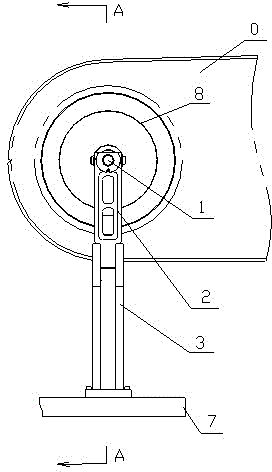

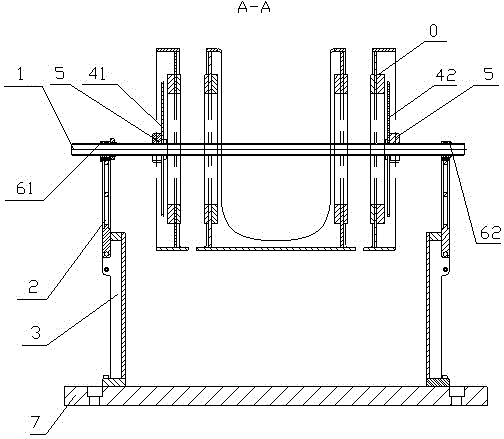

[0024] The present invention will be further described below with reference to the schematic diagram and specific operation examples.

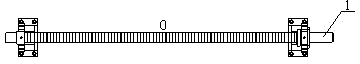

[0025] like figure 1 and figure 2 As shown, the simple detection and alignment mechanism of the boom type workpiece of the present invention includes a main crossbar 1, a bracket 2, a base 3 and a detection plate. The main crossbar 1 is placed horizontally, and is fixed on the bracket 2 through pins and nuts. have a uniform scale, such as image 3 As shown in the figure, the middle is zero scale, and the reading increases to both sides in turn. The specific size of the reference scale depends on the actual size of the workpiece to be measured. The main crossbar 1 is fixed on the base 3 through a bracket 2, and the bracket 2 is connected with the base 3 through pins. The detection board is divided into a left detection board 41 and a right detection board 42, which are respectively fixed on a sliding seat 5. The left detection board 41 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com