excimer lamp

A technology of excimer lamp and external electrode, which is applied in the direction of discharge lamp, discharge tube/lamp manufacturing, gas discharge lamp parts, etc., can solve the problems of affecting, affecting the normal discharge of external electrode 12, unacceptable and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

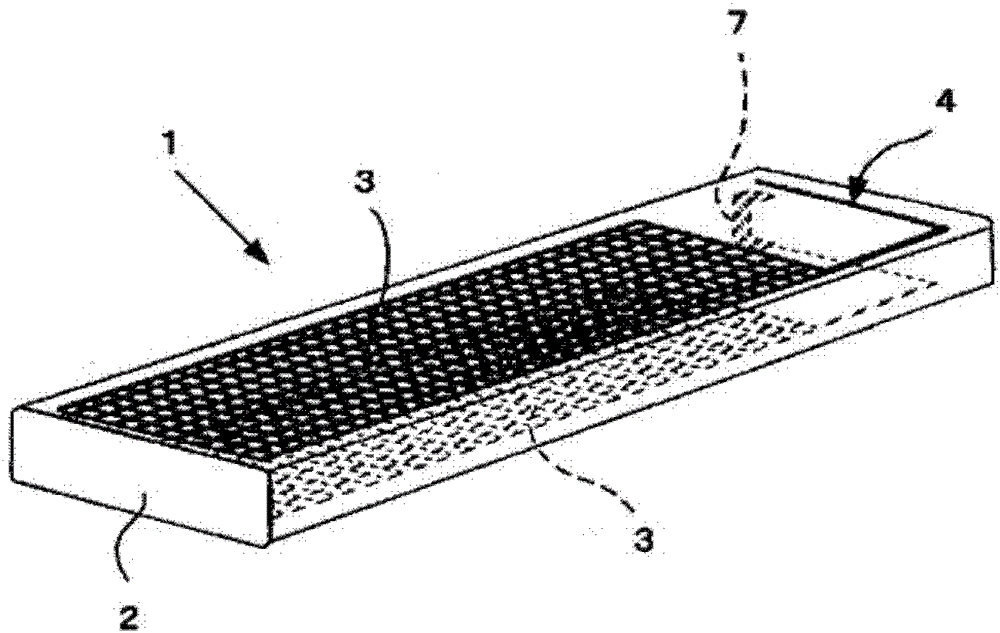

[0051] Such as figure 1 As shown, on the discharge vessel 2 of the excimer lamp 1 of the present invention, a pair of light-transmitting external electrodes 3 and 3 are disposed on opposite sides thereof.

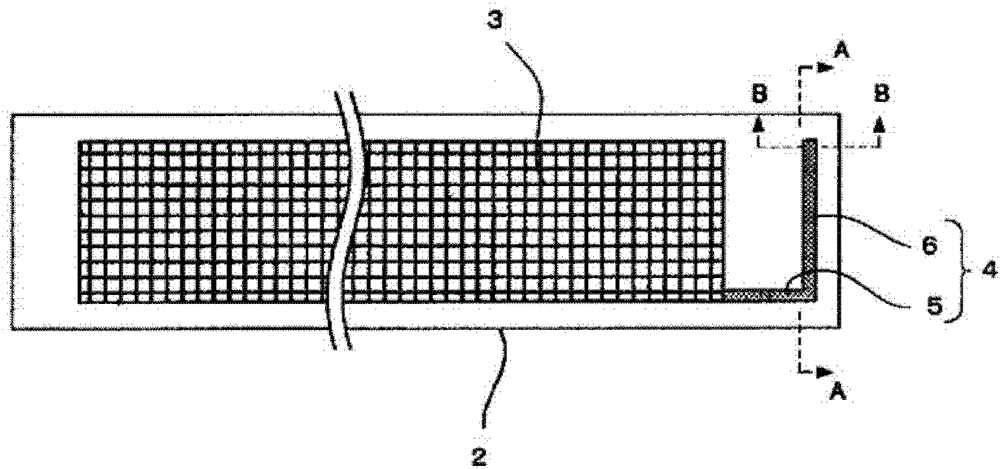

[0052] Such as figure 2 As shown in detail in the subsequent figures, substantially L-shaped dendritic electrodes 4 are provided at the ends of the external electrodes 3 . The dendritic electrode 4 includes a root portion 5 and a branch portion 6, the root portion 5 extending from one end of the external electrode 3 in the width direction of the discharge vessel 2 in the direction of the tube axis, and the branch portion 6 extending from the front end of the root portion 5 toward the end of the discharge vessel 2. The other end side in the width direction extends.

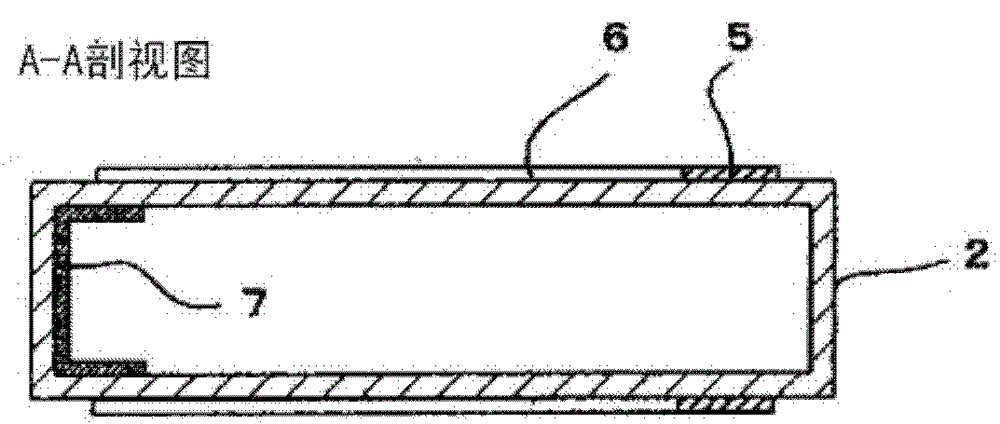

[0053] In particular, as figure 2 A-A cutaway view of image 3 , or as a perspective view of only the dendritic electrode and the starting auxiliary electrode Figure 5As shown, a starting auxiliary elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com