Assembled blade guniting stirring drill bit and using method thereof

An assembled and bladed technology, which is applied in the direction of drilling tools, drill pipes, drill pipes, etc., can solve the problems of uneven mixing, complicated process, and high technical personnel requirements, so as to improve the quality of piles, reduce maintenance time, and improve construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

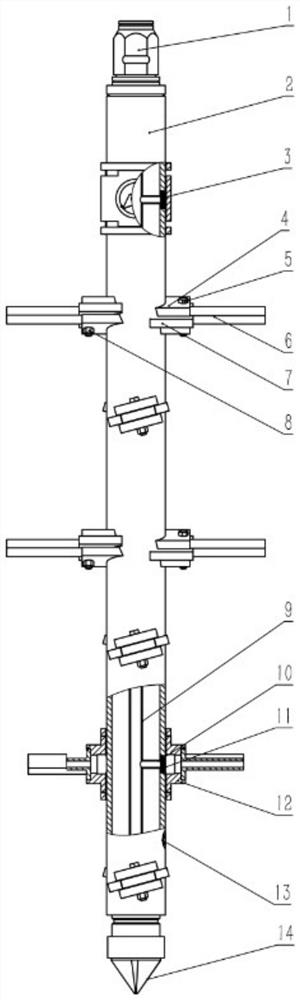

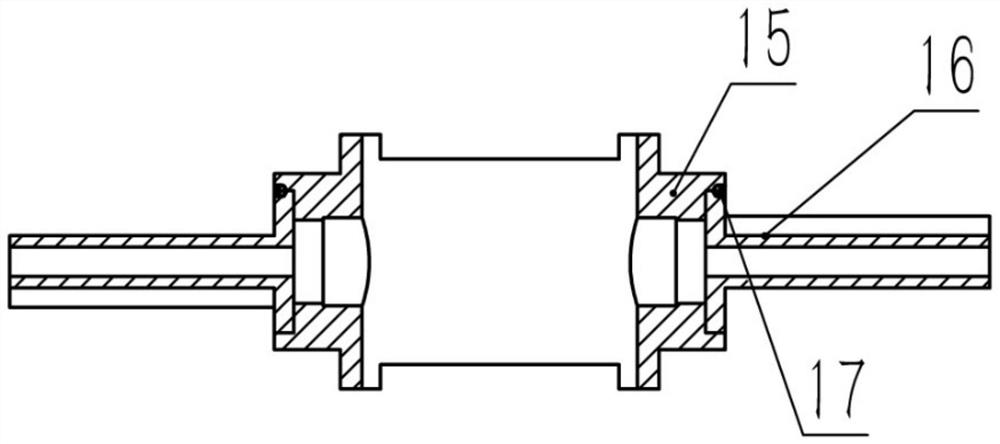

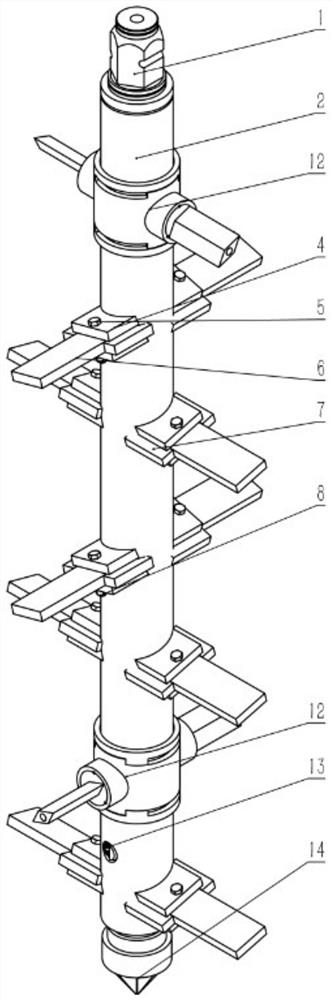

[0020] Such as figure 1 As shown, an assembled blade spraying mixing drill bit and its use method, the drill bit is composed of a hexagonal male joint 1, a drill pipe body 2, an upper spraying port 3, a splint 4, a bolt 5, an assembled blade 6, and an auxiliary splint 7 , a nut 8, a core tube 9, a lower spray nozzle 10, a sealing gasket 11, a spray blade assembly 12, an air injection port 13, and a drill tip 14. The hexagonal male joint 4 is welded on the top of the drill pipe body 2, and the The spraying blade assembly 12 is arranged at the upper and lower ends of the drill pipe body 2, during which a plurality of assembled blades 6 are arranged alternately.

[0021] The invention relates to a method for using an assembled blade spraying and mixing drill bit, which includes:

[0022] When the assembled blade spraying mixing drill bit is used for cement-soil mixing pile construction, the whole drill bit rotates and drills downward, and the spraying blade assembly 12 arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com