Method for improving write margin of static random access memory (SRAM)

A static random, write redundant technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as reducing hole mobility, increase equivalent resistance, and improve write redundancy , the effect of reducing the potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

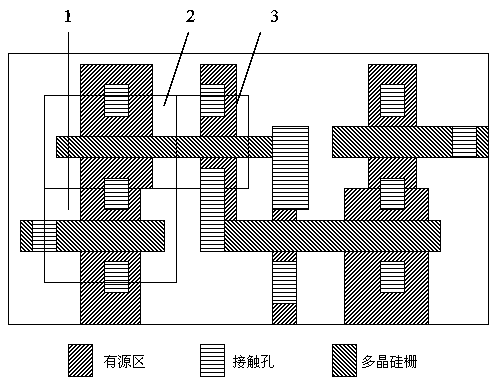

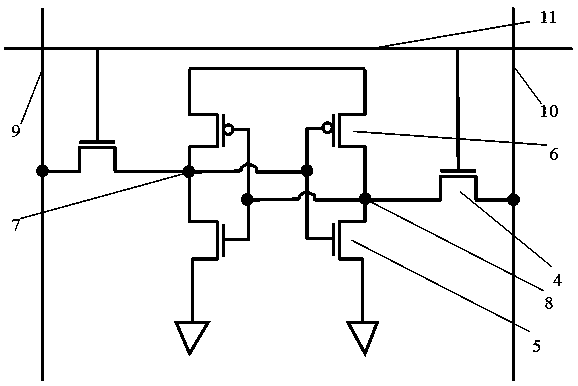

Image

Examples

Embodiment Construction

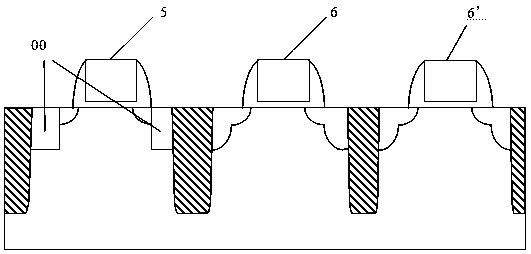

[0024] The present invention will be further described below in combination with principle diagrams and specific operation examples.

[0025] Such as Figure 4 Shown, the present invention improves the method for SRAM writing redundancy, and it comprises the following steps:

[0026] A SRAM substrate 0 is provided, and the substrate 0 includes sequentially adjacent NMOS regions 5, a first PMOS region 6 and a second PMOS region 6', and the first NMOS region 5 is used to prepare common NMOS devices, control transistors and pull-down tube, the first PMOS area is used to prepare a common PMOS device, and the second PMOS area is used to prepare a pull-up tube;

[0027] A shallow trench isolation region (STI) is respectively formed between the NMOS region 5, the first PMOS region 6 and the second PMOS region 6';

[0028] Simultaneously, a silicon carbide epitaxial formation process that generates tensile stress is adopted for the NMOS region 5 and the second PMOS region 6', and si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com