Solar cell module

A technology of solar cells and components, applied in the direction of electrical components, electrical solid-state devices, circuits, etc., can solve the problems of power conversion efficiency and poor lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

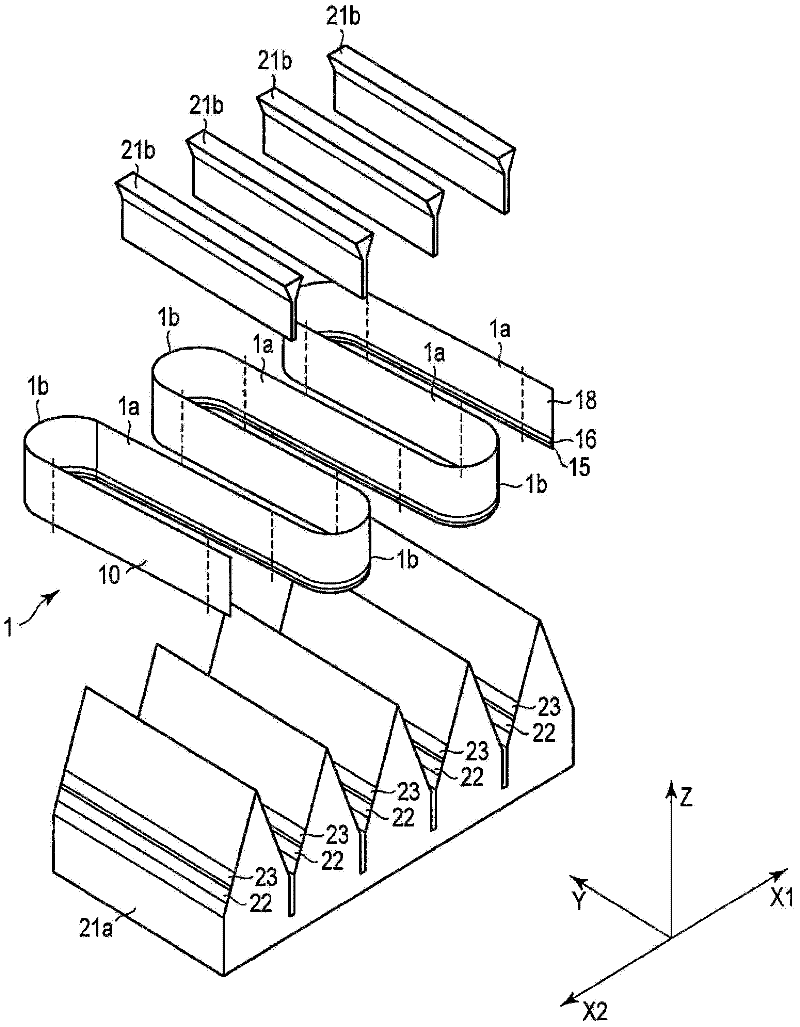

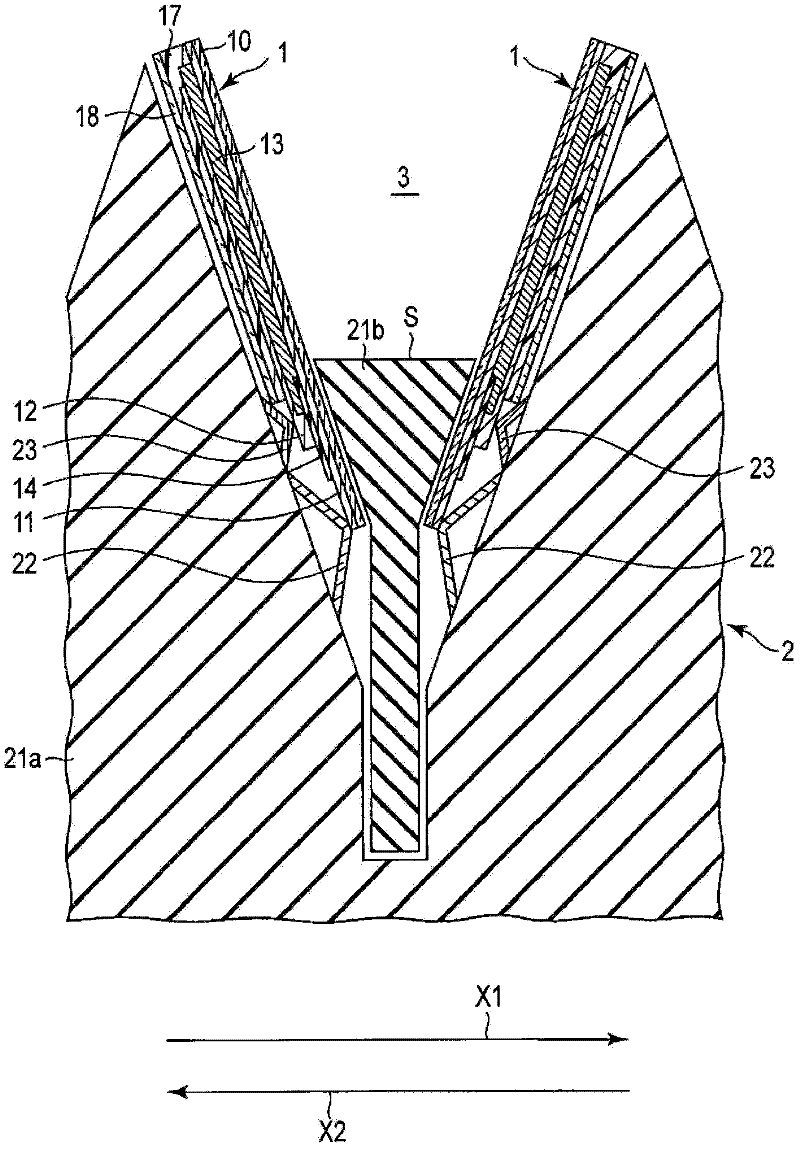

[0194] by and reference Figures 6 to 10 The same method as described is used to fabricate organic thin film solar cell modules in which solar cell devices are formed into multi-slope structures.

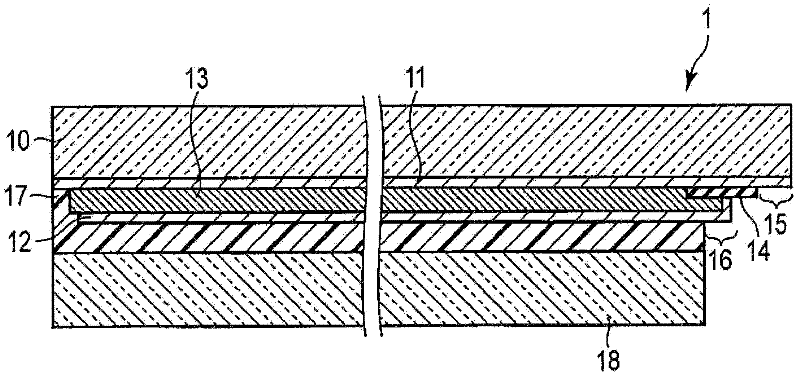

[0195] More specifically, a 150 nm thick ITO layer was first deposited on a 150 μm thick PEN substrate by sputtering. The substrate has a width of 28 mm and a length of 420 mm. Then, by using DL 1000 manufactured by TORAY, a polyimide film having a width of 6 mm was formed as the insulating layer 14 on the ITO layer by photolithography.

[0196] Subsequently, while the strip-shaped substrates are continuously supplied to the coating unit, a hole transport / injection layer, an active layer, and an electron transport / injection layer are sequentially deposited, and a cathode is deposited by vaporization. Immediately before depositing the hole transport / injection layer by coating, the surface is UV cleaned by using a UV cleaner, thereby removing foreign substances from the surface and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com