One-to-many control system of industrial frequency converter for textile machine and realization method

An implementation method and frequency converter technology, applied in the direction of controlling multiple AC motors, etc., can solve the problem that the frequency converter cannot be completed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

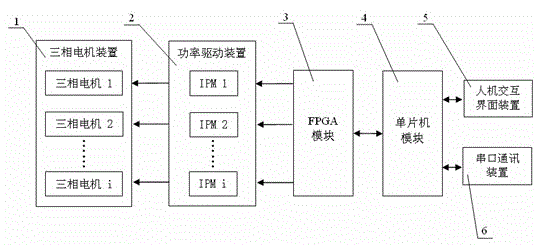

[0015] Such as figure 1 As shown, the one-to-multiple control system for the industrial inverter for textile machinery of the present invention includes a single-chip microcomputer module 4, an FPGA module 3, a human-computer interaction interface device 5, a serial communication device module 6, a power drive device 2 and a three-phase motor device 1.

[0016] The man-machine interaction interface device 5 is connected through the input and output interface of the single-chip microcomputer module 4; the serial port communication device module 6 is connected through the CAN communication interface of the single-chip microcomputer module 4; the single-chip microcomputer module 4 is connected with the FPGA module 3 through the SPI interface, and the FPGA module 3 is connected through the input-output interface It is connected with the power drive device 2; the power drive device 2 is connected with the corresponding three-phase motor in the three-phase motor device 1 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com