Intelligent tobacco stalk detecting and removing device and working method thereof

A rejecting device and intelligent technology, applied in conveyor control devices, tobacco, tobacco preparation, etc., can solve the problems of inability to realize the screening and rejecting of small-shaped, small-stem diameter, and stalked tobacco leaves, multi-manpower, low operation efficiency, etc., and achieve savings. The effect of manpower, improving cigarette quality and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

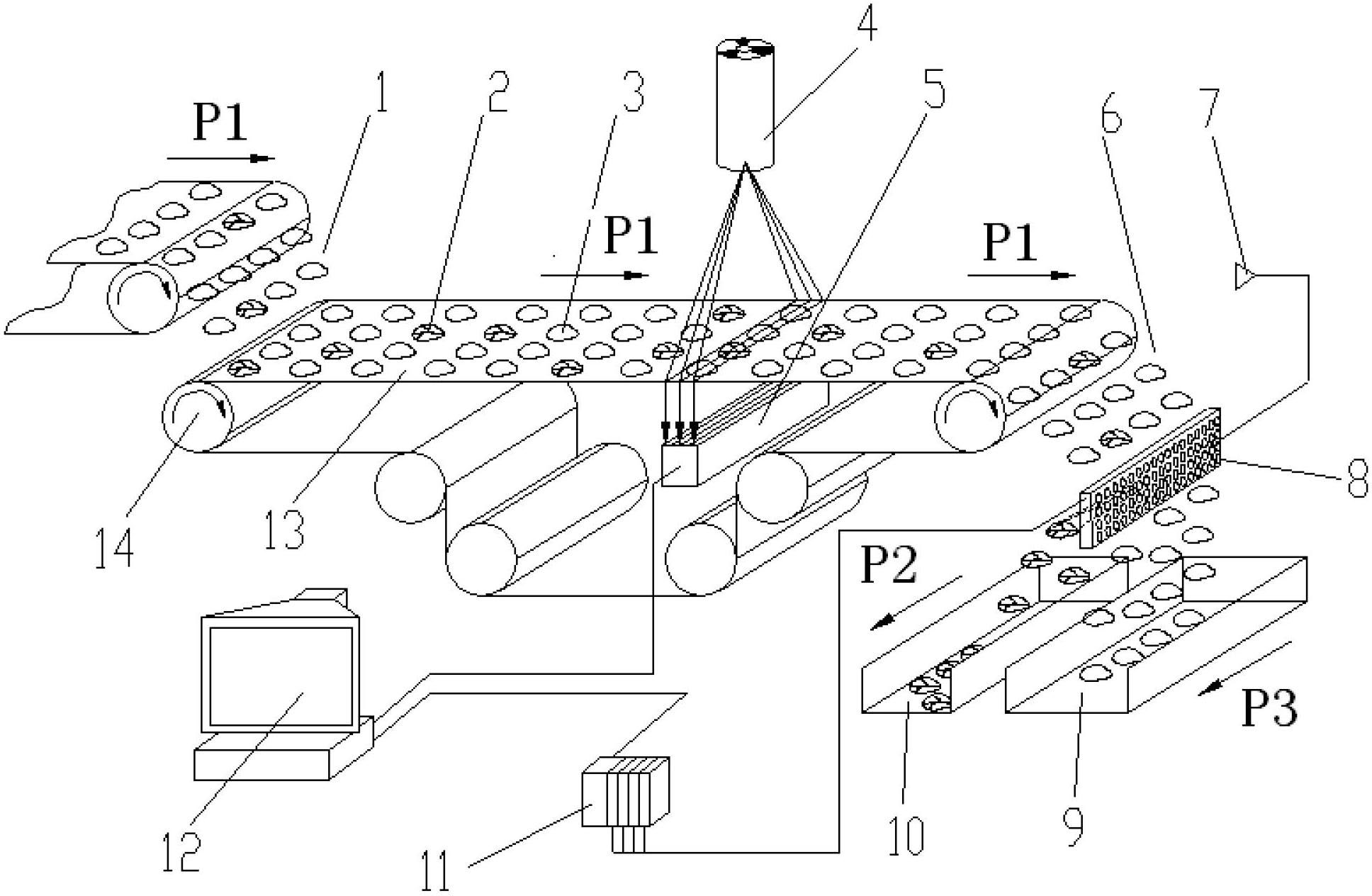

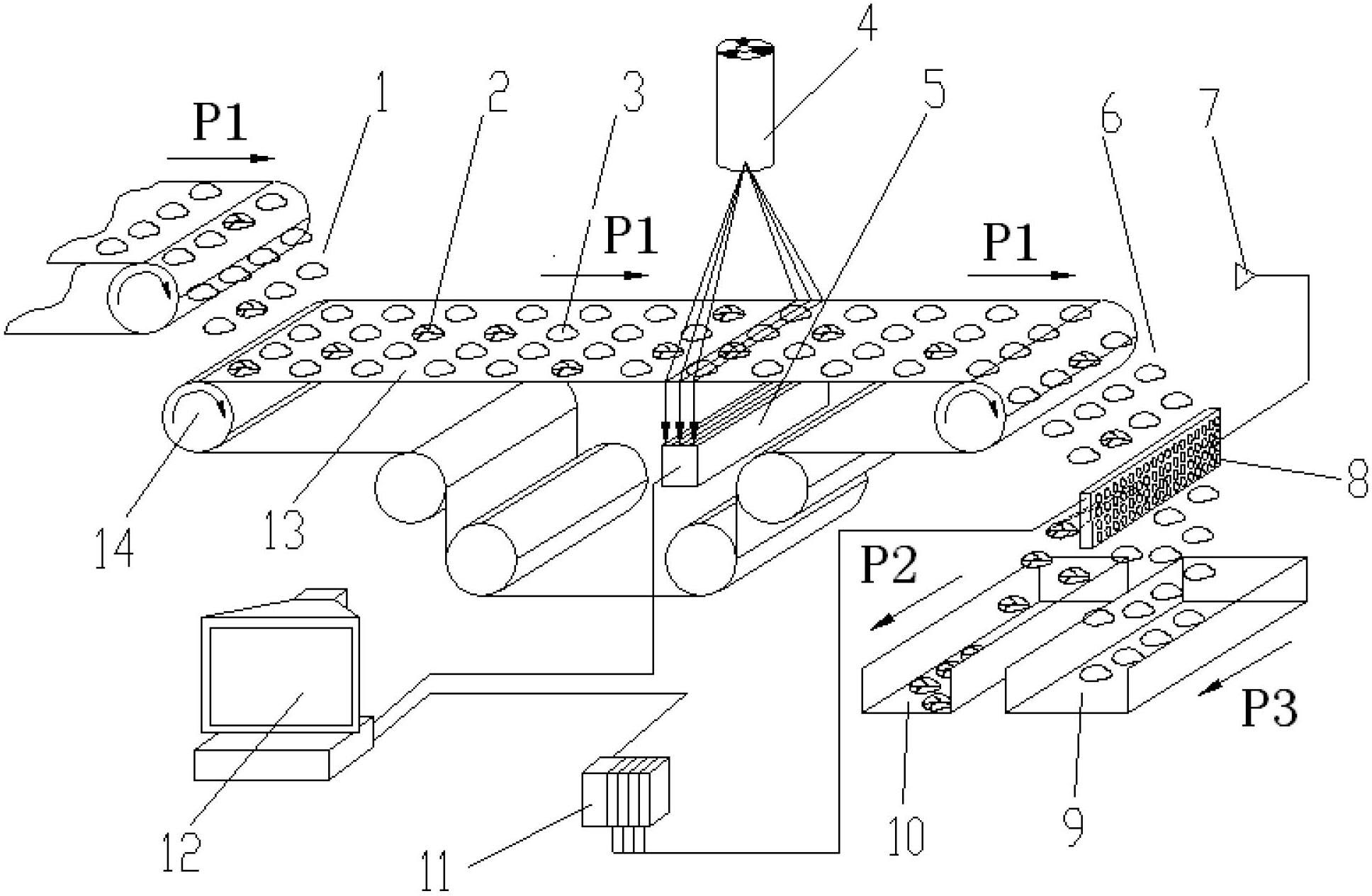

[0015] figure 1 A schematic structural diagram of the intelligent tobacco stem detection and removal device according to the present invention is shown, as figure 1 As shown, the intelligent tobacco stem detection and removal device includes a housing, and the intelligent tobacco stem detection and removal device also includes a conveyor belt 14, an intelligent detection and identification module and an automatic removal module all arranged in the housing .

[0016] Specifically, the intelligent detection and identification module set at the transmission end 6 of the conveyor belt 14 includes a soft X-ray generating tube 4 and a line scanning soft X-ray receiving sensor 5, and the soft X-ray emitted by the soft X-ray generating tube 4 covers the conveying area. The end cross-section of the belt 13 of the belt 14, the soft X-ray runs through the conveyor belt 14 and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com