Tobacco sheet selecting system and technique of tobacco processing line

A technology for making tobacco and silk thread, which is applied in the directions of tobacco, tobacco preparation, conveyor objects, etc., can solve the problems of high-grade cigarette quality, impurity cannot be removed, cannot be removed completely and effectively, etc., so as to improve the quality of cigarettes and avoid tobacco leaves. The effect of breaking and avoiding missed selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The system of the present invention will be further described in the following embodiments in conjunction with the accompanying drawings.

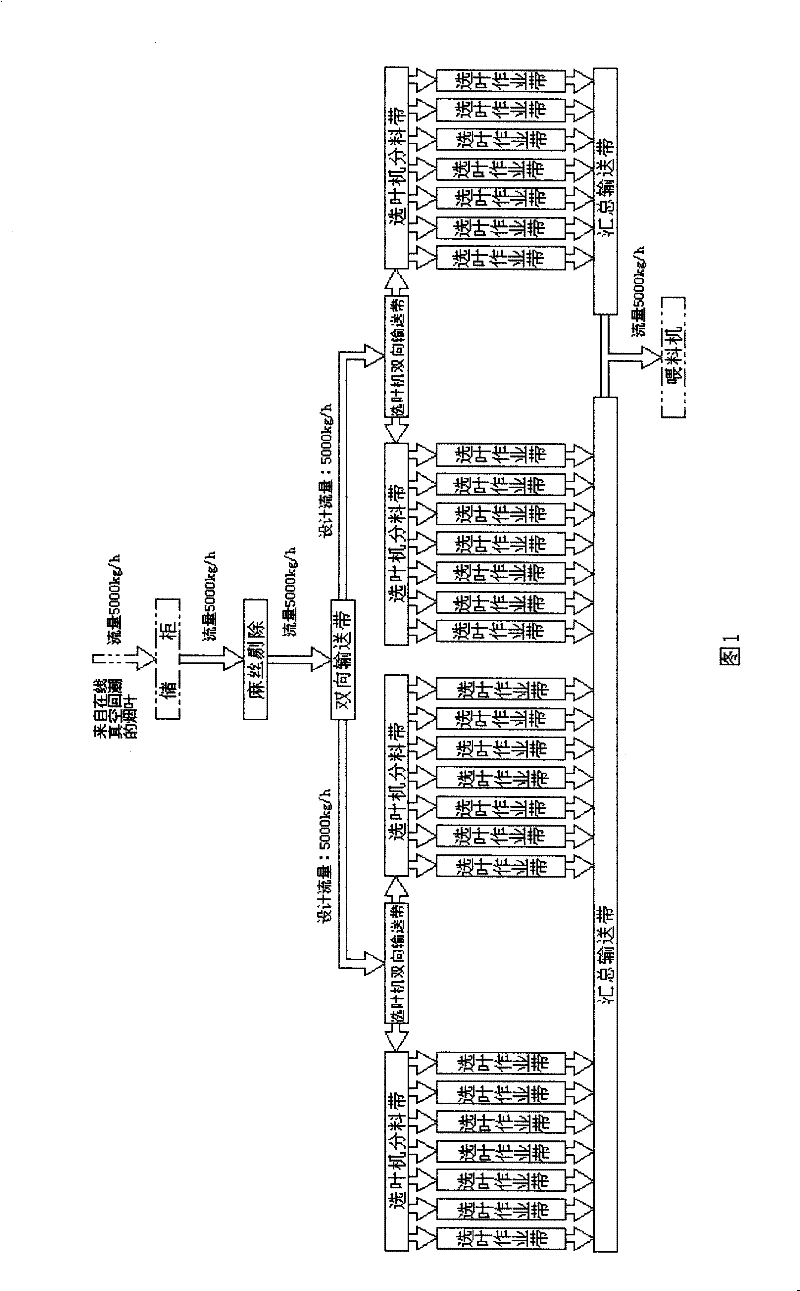

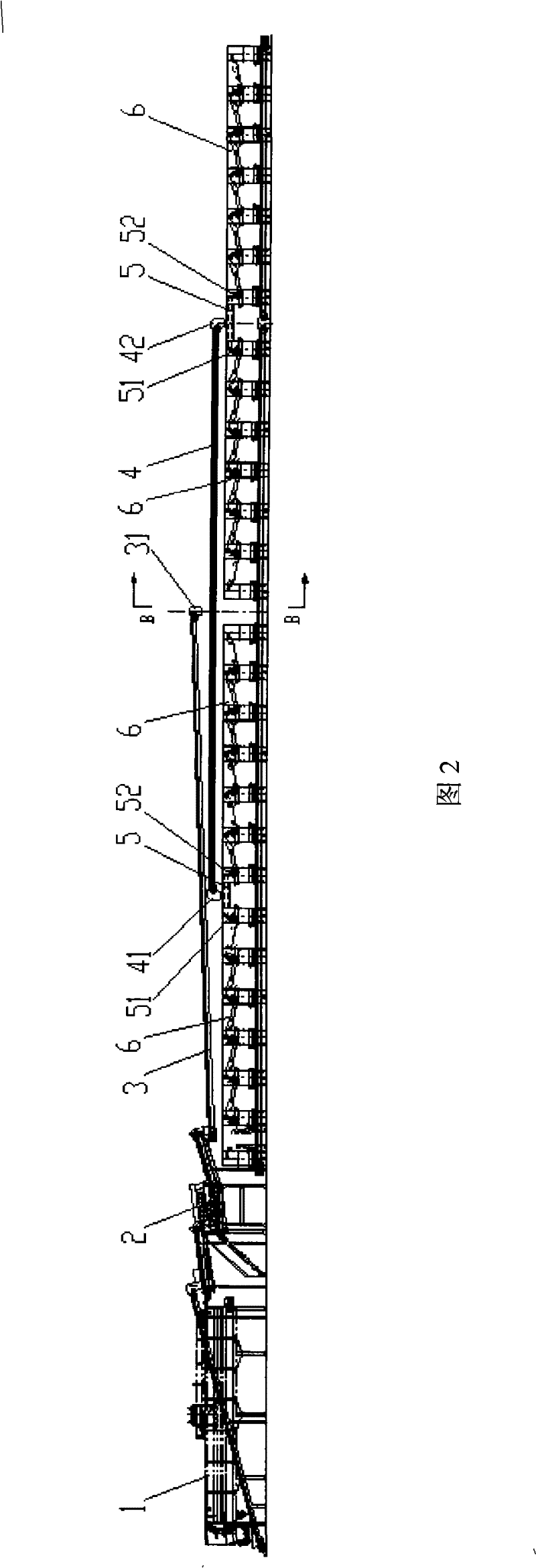

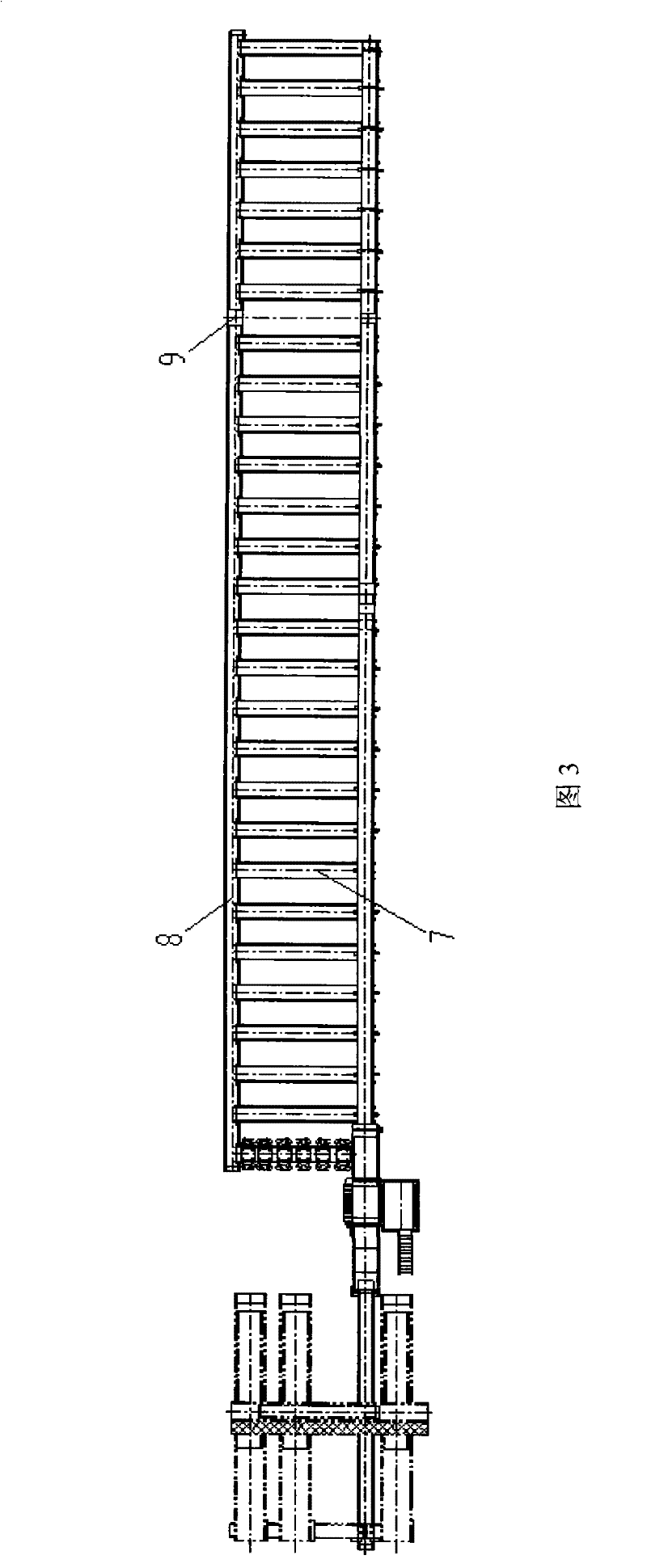

[0028] The system for selecting tobacco shreds and sheets provided by the present invention includes a belt feeding conveyor 3 connected with the smoke storage cabinet 1, a belt receiving conveyor 8 connected with the feeder 9, and a belt feeding conveyor 8 between the smoke storage cabinet 1 and the belt feeding conveyor. The hemp silk rejecting machine 2 is set between the machines 3, such as figure 2 , image 3 , also includes: a belt feeding two-way conveyor 4, the conveyor is located below the belt feeding conveyor 3, and is connected with the feeding conveyor 3 discharge port 31, and its two ends are respectively discharge ports 41, 42 , forming the first level of material distribution, so that the material from the feed conveyor 3 is sent out in turn through the discharge ports 41 and 42 at both ends; two belt material dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com