Improved desulfurizer

A technology for desulfurizers and air intake pipes, applied in the field of desulfurizers, can solve the problems of not meeting the standard requirements, dust removal efficiency, and easy formation of acid rain, etc., and achieve the effect of simple structure, low water content and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

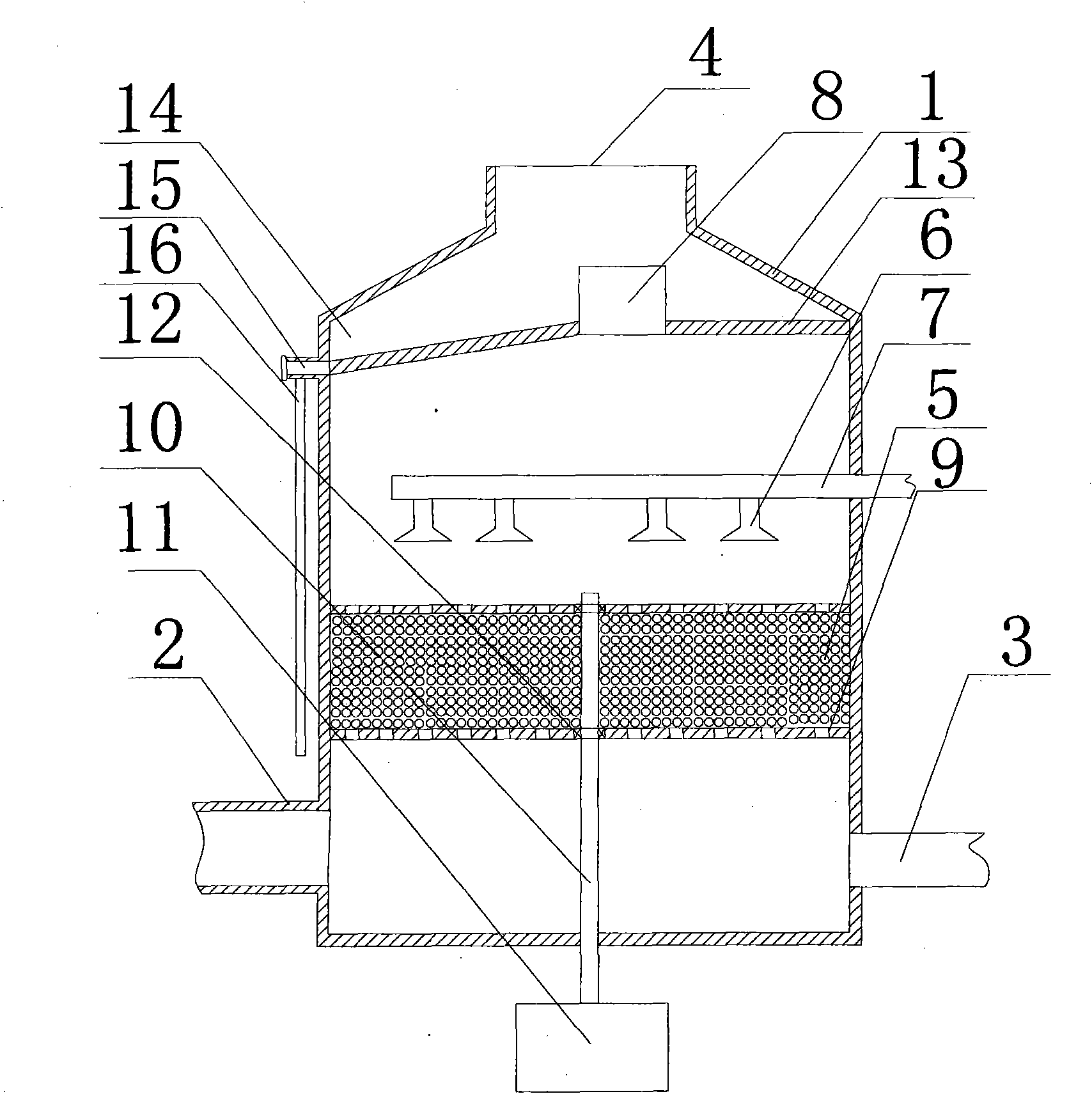

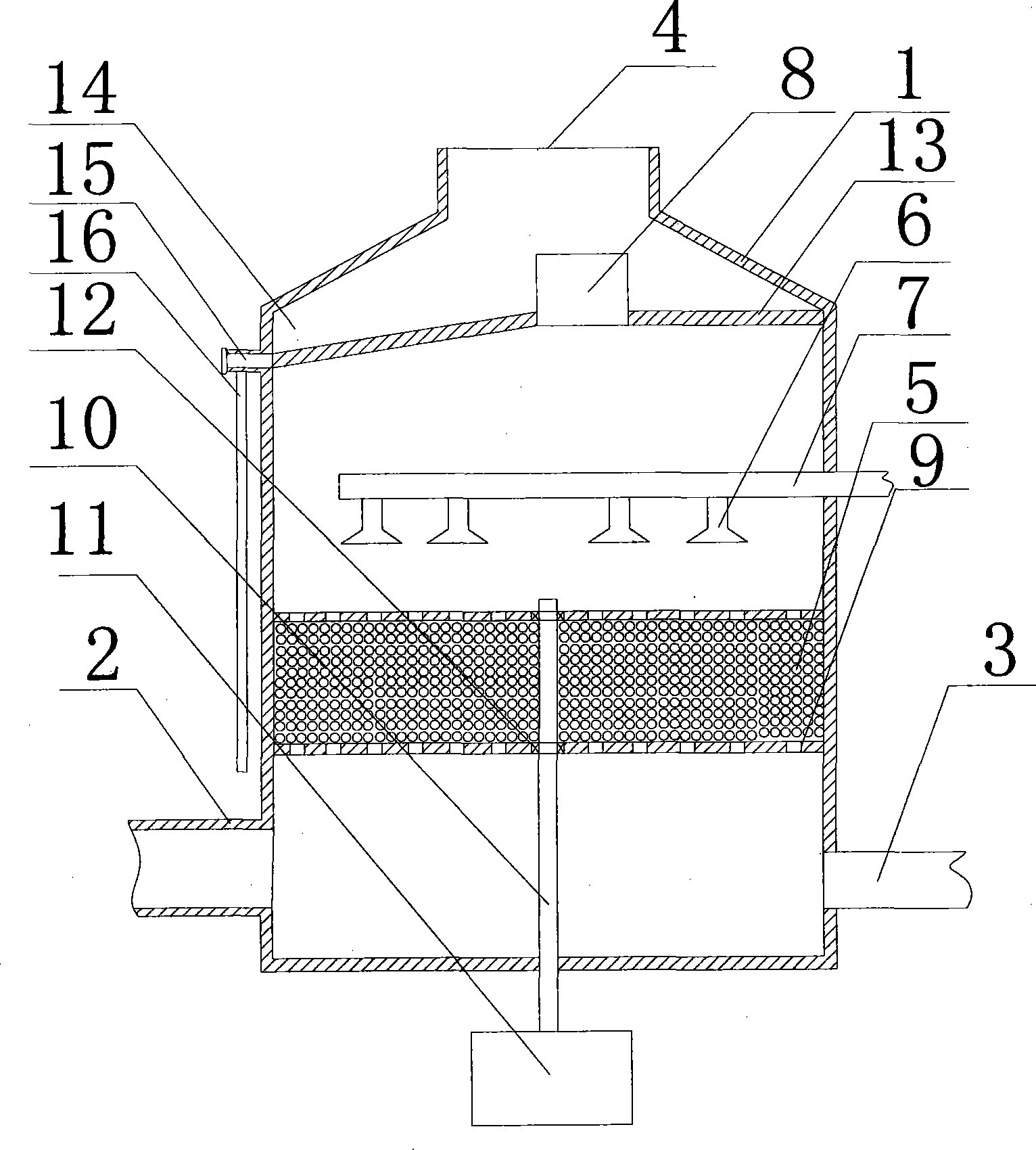

[0010] Such as figure 1 Shown: an improved desulfurizer, including a cylindrical shell 1, an air inlet pipe 2 arranged on the side wall of the lower part of the shell 1, a sewage pipe 3 and an air outlet 4 arranged on the upper part of the shell 1, in the shell 1 The inner middle part is provided with a filter material layer 5, and a certain number of water spray devices 6 are arranged on the upper part of the filter material layer 5. The water spray devices 6 pass through the side wall of the housing 1 through the pipeline 7 and are connected to the outside of the housing 1. The filter material layer The two ends of 5 are provided with a mesh support plate 9 matching the cross section of the housing 1, and a rotating shaft 10 is arranged inside the housing 1, and one end of the rotating shaft 10 is fixedly connected with the central parts of the upper and lower mesh support plates 9, The other end of the rotating shaft 10 passes through the bottom of the housing 1 and is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com