Idler wheel for conveying glass substrates

A technology of glass substrates and rollers, which is applied in the manufacture of conveyor objects, electrical components, semiconductors/solid-state devices, etc., can solve the problems of manpower, waste, and consumption, and achieve the effects of saving costs and reducing defective rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be practiced.

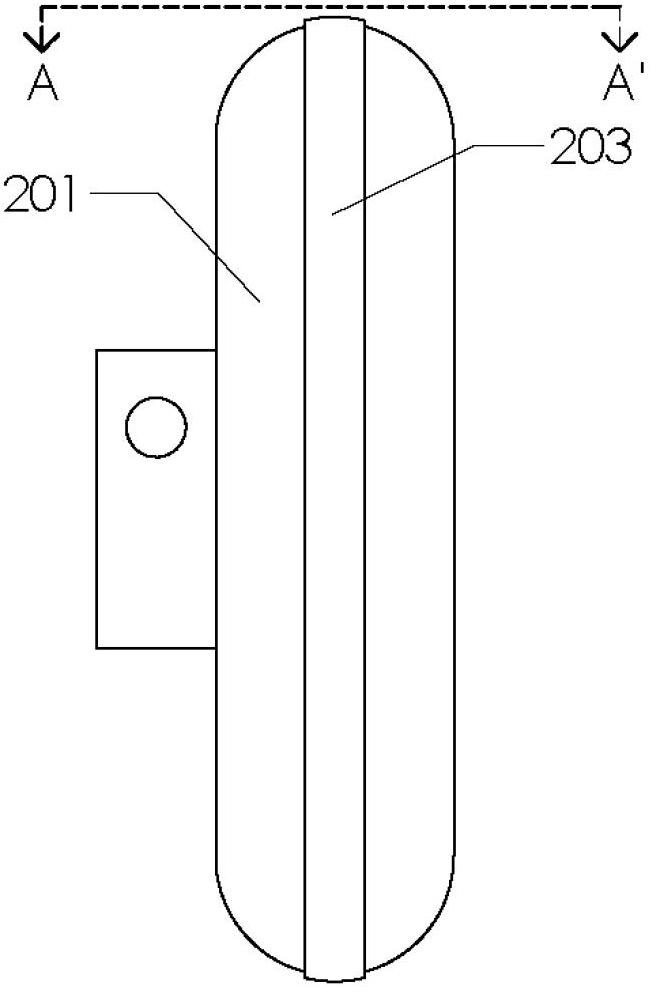

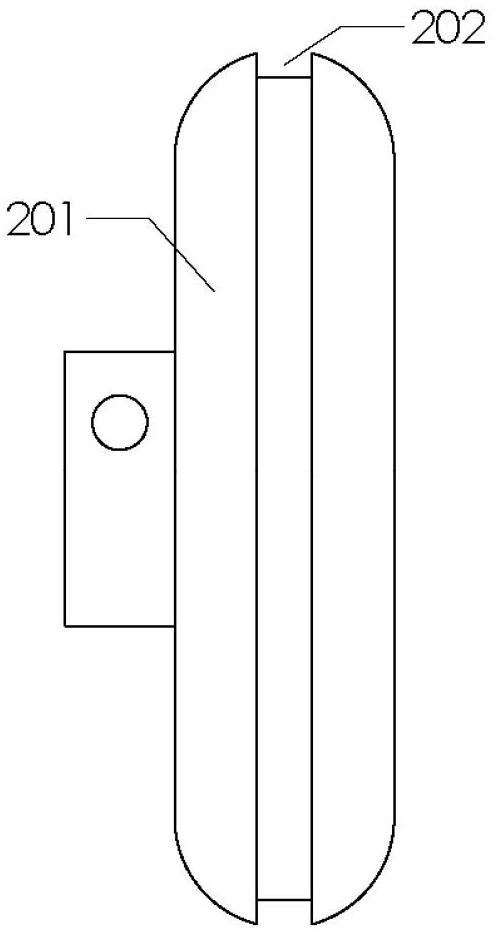

[0026] refer to figure 2 , figure 2 It is the front view of the first embodiment of the roller of the present invention. In this embodiment, the roller for conveying glass substrates of the present invention includes a roller body 201 and a peripheral member 203, the roller body 201 has a convex circumferential surface, and the peripheral member 203 is integrated with the roller body 201, specifically Specifically, the peripheral member 203 is nested at the outermost circumference of the convex circumferential surface of the roller main body 201 . The material of the peripheral member 203 is a material whose hardness value is lower than that of the glass substrate, such as rubber or plastic. In this embodiment, since the peripheral member 203 is provided at the outermost circumference on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com