Horizontal continuous casting graphite crystallizer by aid of nitrogen protection method

A graphite crystallizer and horizontal continuous casting technology, which is applied in the field of metallurgical equipment, can solve problems such as scratches on the inner wall of graphite, short service life of graphite crystallizers, and increased scratches on the inner wall of graphite crystallization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

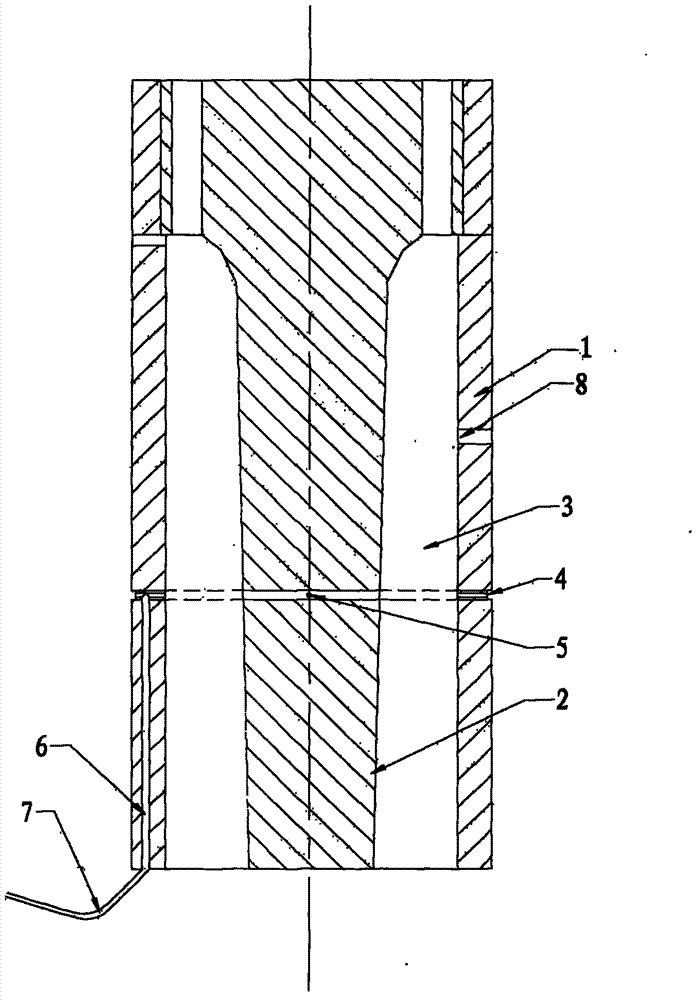

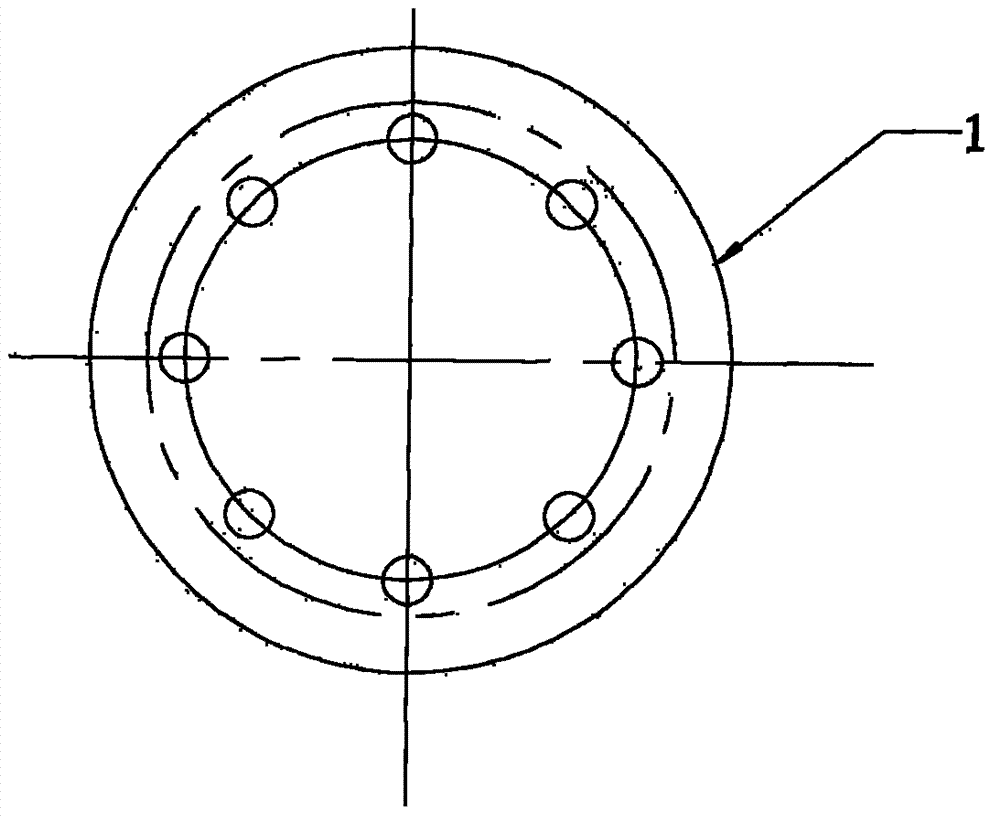

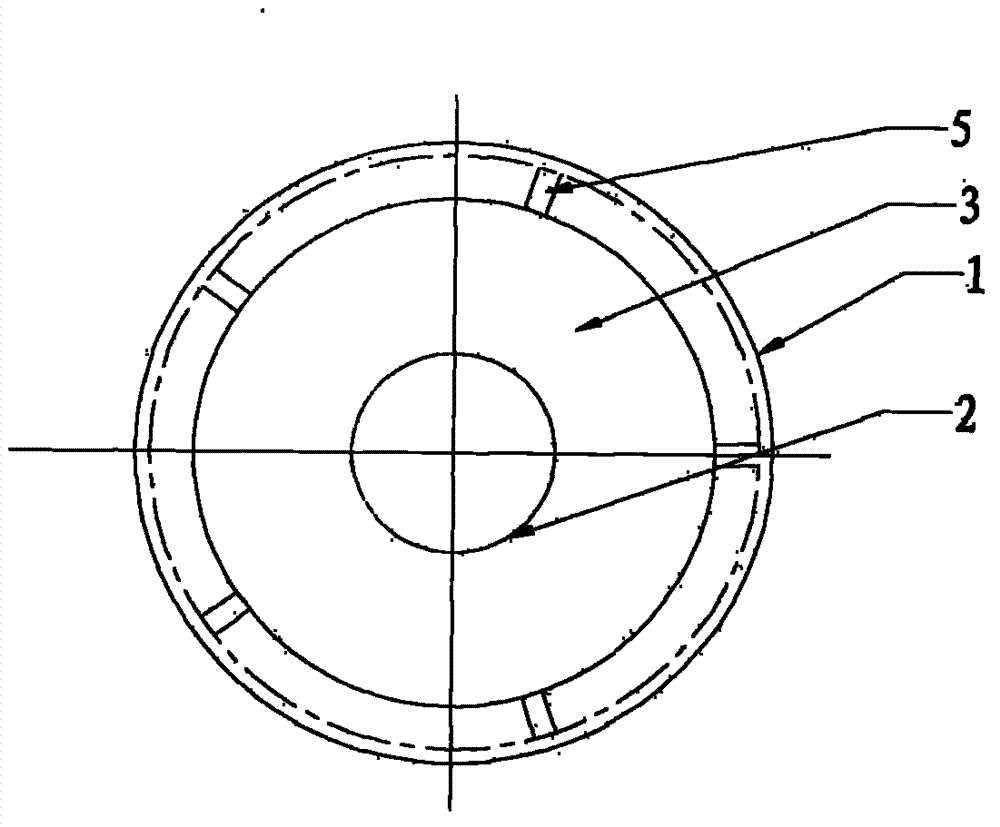

[0011] As shown in the figure, the nitrogen protection method horizontal continuous casting graphite crystallizer of the present invention comprises a tubular graphite sleeve 1, and a fixed diameter graphite rod 2 is arranged in the graphite sleeve 1, and a graphite rod 2 is formed between the graphite sleeve 1 and the graphite rod 2. The crystal cavity 3, the periphery of the lower end of the graphite sleeve 1 is milled with an annular groove 4, and the annular groove 4 is drilled with a through hole 5 communicating with the crystal cavity 3; the bottom end of the graphite sleeve 1 is drilled with a communication hole 6, and the communication hole 6 is connected to the The through holes 5 communicate with each other, and a capillary tube is arranged in the communication hole 6 , and the capillary tube is connected to a nitrogen gas pipe 7 . The number of said through holes 5 is more than 5 and they are uniformly arranged on the annular groove 4 .

[0012] On the basis of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com