3D contour online measuring instrument

A measuring instrument and profile technology, applied in the field of measuring instruments, can solve the problems of small vertical measurement range, high measurement efficiency, unfavorable installation, etc., achieve excellent angle characteristics, high-precision online 3D profile measurement, and reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

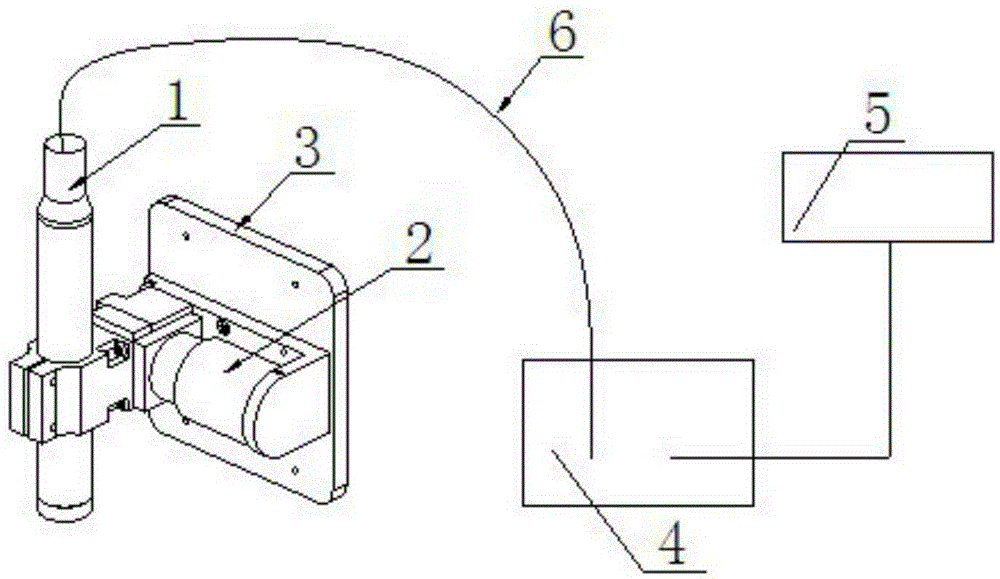

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0030] At first relevant technical terms in the present invention are explained:

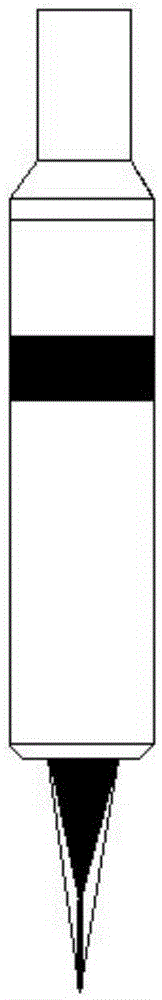

[0031] Confocal displacement meter: Confocal displacement meter is a new type of ultra-high precision and ultra-high stability non-contact optical displacement measuring instrument. Dispersion, forming a series of monochromatic light with different wavelengths on one axis, each wavelength corresponds to a distance value to the measured object. The surface of the object reflects the irradiated light back and filters it through the confocal aperture. Only the monochromatic light that meets the confocal condition can be sensed by the spectrometer through the aperture. By calculating the sensed wavelength, the distance value is converted.

[0032] Piezoelectric linear actuator: it uses piezoelectric ceramic substrates or thin films, electrostrictive materials and other func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com