Movable discharging rack

An unloading rack, movable technology, applied in thin material handling, strip winding, transportation and packaging, etc., can solve the problems of inconvenient handling and movement, inability to flexibly combine, and inability to simultaneously discharge materials from multiple racks, etc. To achieve the effect of stable fixation, compact device structure and uniform spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

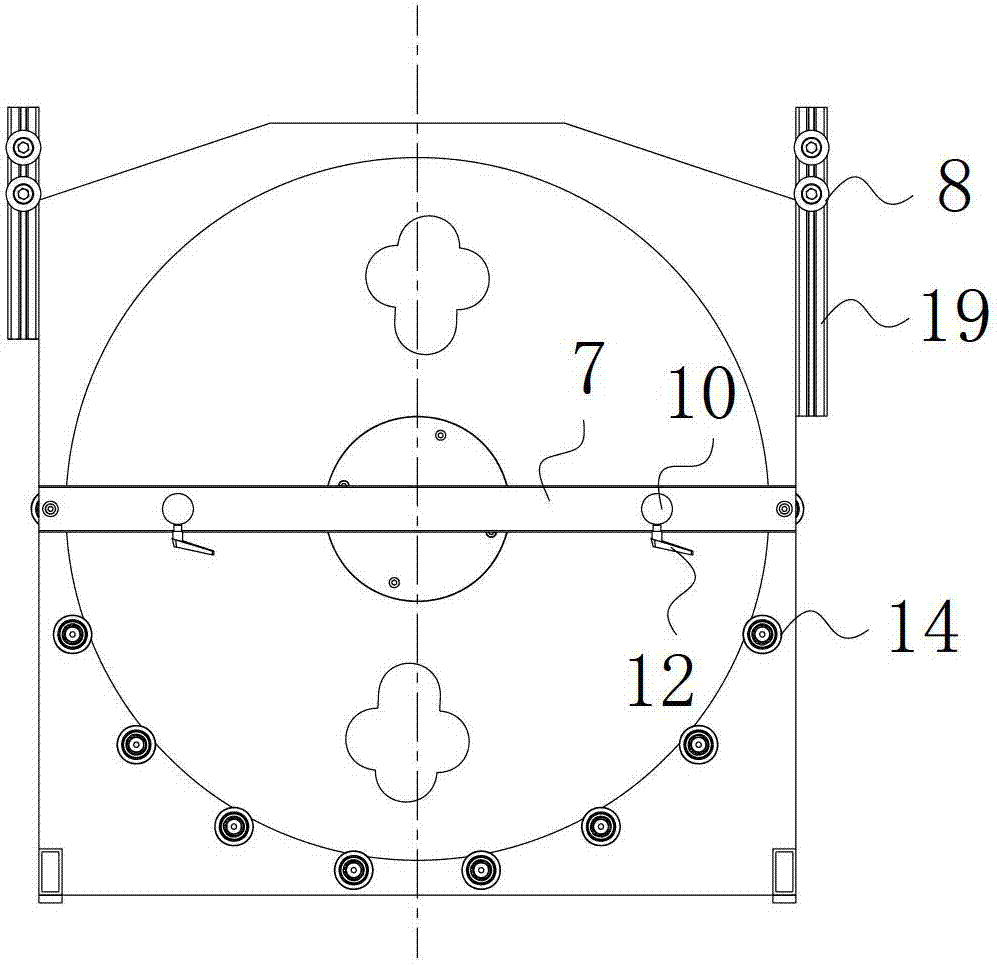

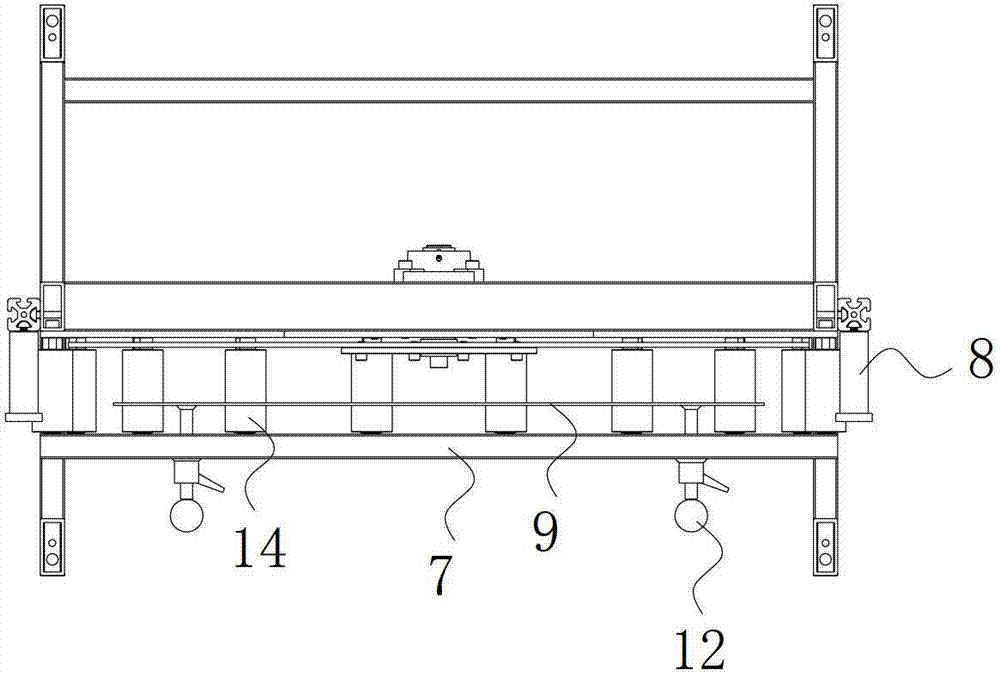

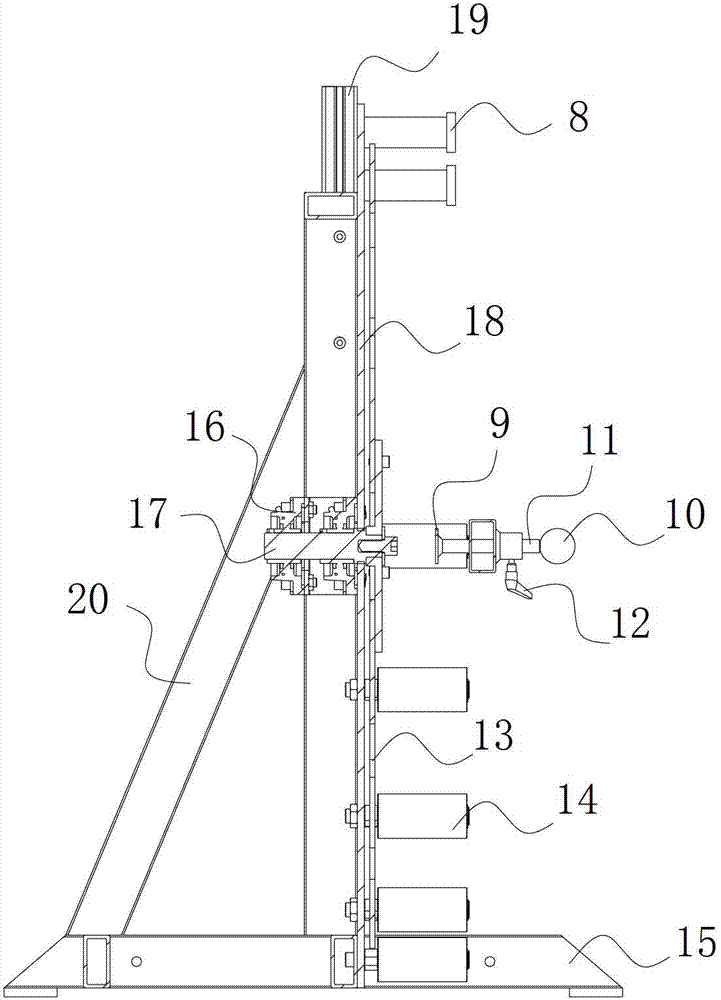

[0037] Such as figure 1 , figure 2 , image 3 As shown, the movable discharge rack of the present invention includes a support frame 15 , a material tray 13 rotatably connected to the support frame 15 , a material blocking device installed on the support frame 15 and a raw material support wheel 14 pivotally connected to the support frame 15 .

[0038] The support frame 15 includes a base and a wallboard 18 standing on the base. The vertical wallboard 18 is fixed with a bearing 16. The bearing 16 is passed through a feeder shaft 17 that rotates with it, and the feeder 13 is fixed on the feeder shaft 17. At one end, the material tray 13 can rotate freely relative to the wallboard 18. The raw material is placed between the material tray 13 and the material blocking device, and the raw material is coiled into a disk shape. When discharging, the freely rotatable material tray 13 can reduce its contact with The friction between raw materials is beneficial to the discharge.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com