Non-silicon release paper

A non-silicon release and non-silicon technology, which is applied in papermaking, paper coating, textiles and papermaking, etc., can solve the problems of variable delivery time and high cost, and achieve the effects of easy identification, uniform coating, and low water and moisture absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The non-silicon release paper of the present invention is mainly applied to flexible circuit board cover films. In a preferred embodiment of the present invention, it is applied to polyimide (PI) cover films as an example.

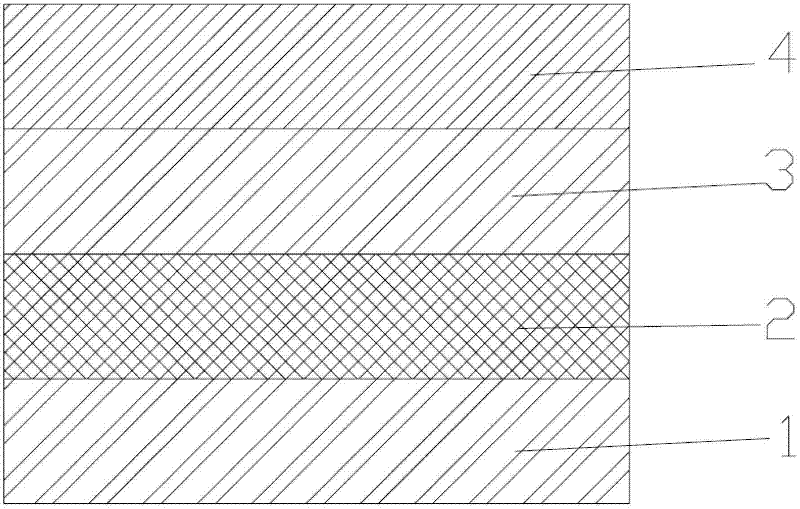

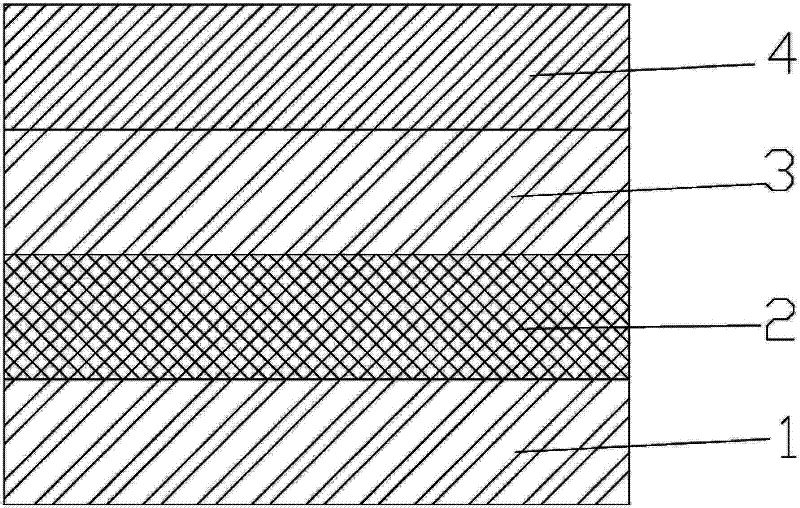

[0022] Such as figure 1 As shown, the non-silicon release paper in the preferred embodiment of the present invention includes plastic coating layer 1, base paper 2, plastic coating layer 3, and non-silicon release layer 4 from bottom to top.

[0023] The above-mentioned base paper can be selected from a base paper made from long-fiber base pulp with high density, and its weight is preferably 70 g, 80 g or 90 g. The coating plastic is preferably a mixture of low-density polyethylene (LDPE) and high-density polyethylene (HDPE), and more preferably low-density polyethylene (LDPE) and high-density polyethylene (LDPE) with a weight percentage of 2:8 or 3:7 or 4:6 A mixture of ethylene (HDPE). The non-silicon release agent is preferably a urethane release co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com