Greenhouse fruit and vegetable receiving and conveying robot

A technology for robots and fruits and vegetables, applied in the field of agricultural robots, can solve the problems of automatic production obstacles of fruits and vegetables, limited carrying space and carrying capacity, affecting the efficiency of picking operations, etc., to reduce difficulty, increase carrying capacity, and achieve the effect of collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

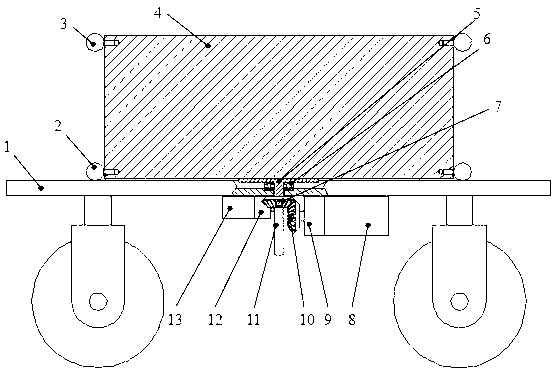

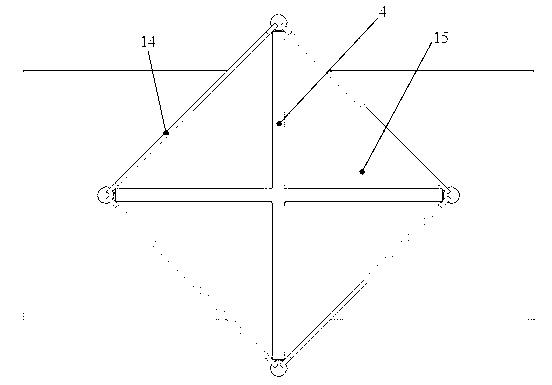

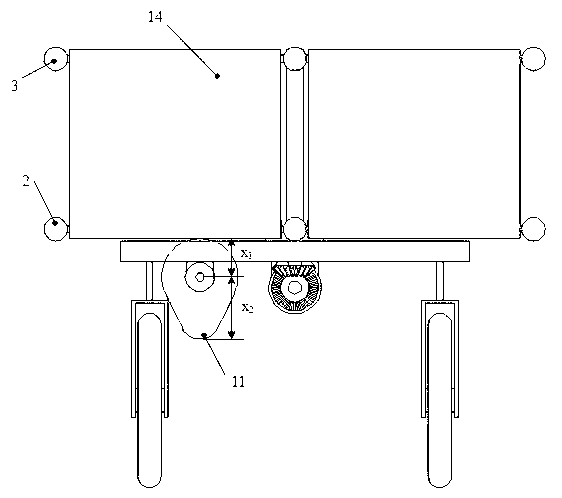

[0014] like Figure 1 to Figure 4 As shown, the greenhouse fruit and vegetable pick-up robot is composed of an autonomous mobile trolley 1, a turntable fruit receiving mechanism and a dumping and unloading mechanism.

[0015] Wherein the rotary table fruit receiving mechanism includes a spacer 4, a rotary table 5, a thrust ball bearing 6, a vertical direction bevel gear 7, a horizontal direction bevel gear 10, a rotary table motor 8, and a rotary table motor reducer 9. The spacer 4 is fixed on the turntable 5, and a thrust ball bearing 6 is installed between the turntable 5 and the body of the self-moving trolley 1. The vertical direction bevel gear 7 is installed on the extension shaft of the turntable 5, the horizontal direction bevel gear 10 is installed on the extension shaft of the turntable motor reducer 9, and the turntable motor reducer 9 is installed on the extension shaft of the turntable motor 8, Turntable motor 8 is fixed under the car body of autonomous mobile do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com