Acid preparation system for storage battery

A storage battery and acid dispensing technology, which is applied in the manufacture of secondary batteries, mixer accessories, mixers, etc., can solve the problems of harsh acid dispensing environment, difficulty in controlling liquid flow, and large acid dispensing accuracy, so as to reduce chemical burn accidents and reduce flow rate Stable and improve the effect of acid mixing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

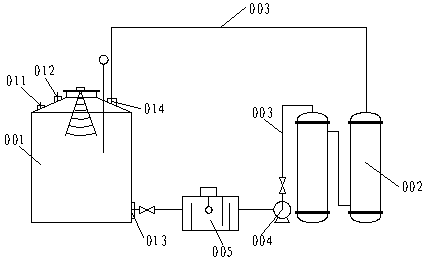

[0018] Embodiment 1: A battery acid distribution system, including an acid distribution storage tank 001 and a cooling device 002, the upper end of the acid distribution storage tank 001 is provided with a water inlet 011 and an acid inlet 012, and the lower end of the acid distribution storage tank 001 is provided with a liquid outlet 013, the liquid outlet 013 is connected to the acid distribution pump 004 through the delivery pipeline 003, the acid distribution pump 004 is connected to the cooling device 002 through the delivery pipeline 003, and the cooling device 002 is connected to the liquid inlet 014 at the upper end of the acid storage tank 001 through the delivery pipeline 003, forming Circulating delivery pipeline, the delivery pipeline 003 between the acid distribution storage tank 001 and the cooling device 002 is additionally equipped with a density detection device 005, preferably the density detection device 005 is set at the liquid outlet 013 at the lower end of...

Embodiment 2

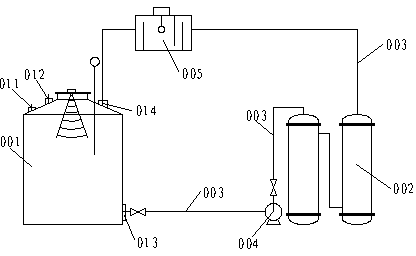

[0019] Embodiment 2: Referring to Embodiment 1, a storage battery acid dispensing system, the density detection device 005 is arranged on the delivery pipe 003 between the cooling device 002 and the liquid inlet 014 at the upper end of the acid dispensing storage tank 001 .

Embodiment 3

[0020] Embodiment 3: Referring to Embodiment 1, a battery acid distribution system, a bypass delivery pipeline 006 is added between the cooling device 002 and the liquid inlet 014 at the upper end of the acid distribution storage tank 001, and the density detection device 005 is installed in the bypass On the delivery pipeline 006.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com