Method for producing active carbon for gasoline vapor adsorption

A production method and activated carbon technology, applied in chemical instruments and methods, inorganic chemistry, other chemical processes, etc., can solve the problems of excessive dust on the carbon surface, increase airflow resistance, shorten service life, etc. Resistance, the effect of prolonging the period of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

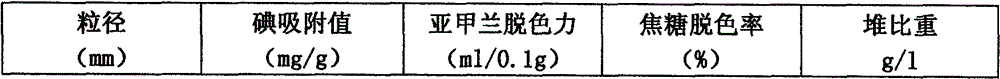

Embodiment 1

[0024] 1. Phosphoric acid is used as a chemical activator, and wood chips are used as raw materials. After the wood chips are dried, they are pulverized with a Raymond mill to a powder finer than 80 mesh. 500kg of dry wood flour is blended with 500kg of industrial phosphoric acid with a concentration of 85%. After the blend is uniform, it is soaked in a pool. After soaking for 10 hours, it is kneaded in a kneader with electric heating function. The kneading temperature is kept at 80-90 °C, kneading time 2.5 hours.

[0025] 2. The kneaded material is placed in the mold of the extruder, and the extruder is heated by electricity at a heating temperature of 120°C. The extruder extrudes strips of Φ2.5mm. It can increase the specific gravity and wear resistance of activated carbon.

[0026] 3. Put the strips into the drying furnace. The drying time of the strips in the furnace is about 6 hours, and the drying temperature is 90-140°C.

[0027] 4. Put the drying material into the ...

Embodiment 2

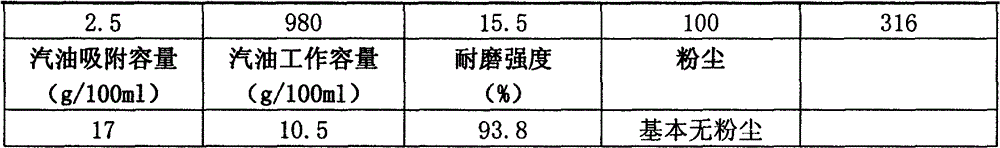

[0033] 1. Use undried wood chips with a moisture content of 10%. Use 675kg wood chips and soak them in 1000 kg of phosphoric acid with a concentration of 85%. After soaking for 8 hours, knead them in a kneader at a temperature of 95°C for 3 hours.

[0034] 2. Extrude the kneading material, the extruding temperature is 120°C, and the Φ2.5mm mold is still used.

[0035] 3. Dry the strips in the dryer for 8 hours at a drying temperature of 105°C.

[0036] 4. The drying material is activated in the rotary kiln, the activation temperature is 480°C, and the activation time is 5 hours.

[0037] 5. After soaking the activated carbon in water to recover phosphoric acid, the wet carbon is put into the calciner, the temperature rises to 1050°C, and the calcining time is 40 minutes. At this time, the charcoal surface is shiny.

[0038] The technical index of gained product detection is as follows:

[0039]

Embodiment 3

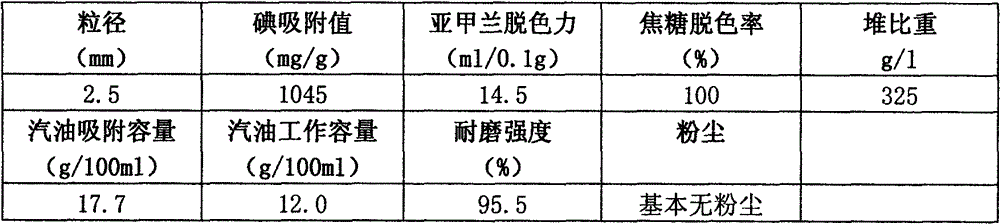

[0041] 1. Provide 1000kg of wood chips and 150kg of coal powder, soak them with 2300kg of zinc chloride with a concentration of 56%, soak for 10 hours, knead in a kneader at a temperature of 95°C, and knead for 2 hours.

[0042] 2. Extrude the kneading material, the extruding temperature is 120°C, and the Φ2.5mm mold is still used.

[0043] 3. The strips are dried in the dryer for 7.5 hours at a drying temperature of 110°C.

[0044] 4. The drying material is activated in the rotary kiln, the activation temperature is 480°C, and the activation time is 6 hours.

[0045] The technical index of gained product detection is as follows:

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com