Method and apparatus for purifying phosphoric acid solutions

A technology of phosphoric acid solution and oxalic acid solution, applied in chemical instruments and methods, separation methods, radioactive purification, etc., can solve the problems of unrealizable, small revenue of mobile equipment, etc., and achieve the effect of reducing the working volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

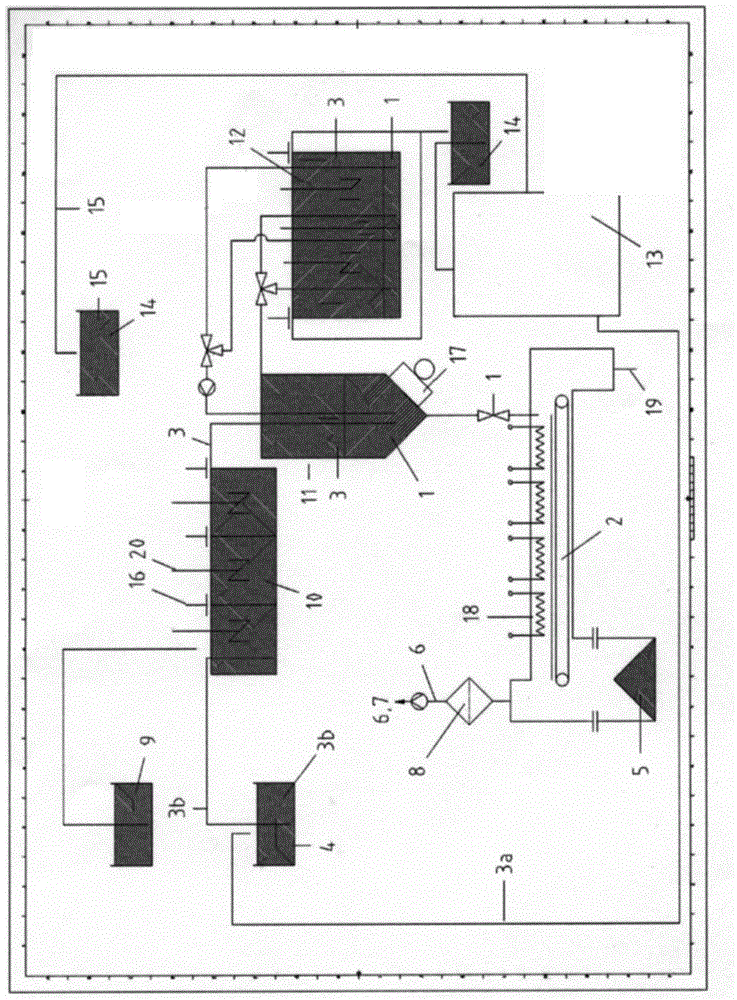

[0032] Shown in the drawing is a plant for purifying a phosphoric acid solution 3b comprising a purifying tank 4 in which phosphoric acid containing dissolved iron(II) and iron(III) is present. The phosphoric acid is fed via pipes and pumps to a multistage mixer 10 in which an agitator 20 is arranged. Oxalic acid 9 is pumped into a multistage mixer 10 from another container. An overflow opening 16 is provided between the container and the multistage mixer 10 . From the mixer 10 is pumped diluted phosphoric acid 3 which reaches a settling tank 11 in which diluted phosphoric acid 3 and iron oxalate deposits 1 are produced by a settling process. On the lower part of the settling tank 11 there is a vibration mechanism 17 . The vibrating mechanism ensures that the sediment does not solidify and can be drained completely downwards. Below the settling tank 11 there is provided a heater, which is a belt furnace 2 and in the present case a plurality of heating elements 18 above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com