Crushing, grinding and grading integrated machine

A crushing machine and integrated machine technology, which is applied in the fields of grading integrated machine, grinding, and crushing. It can solve the problems of difficult sampling of grinding equipment, increased equipment loss and power consumption, and low service life of bearings. types, reduce the crushing process, and ensure the effect of grinding particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

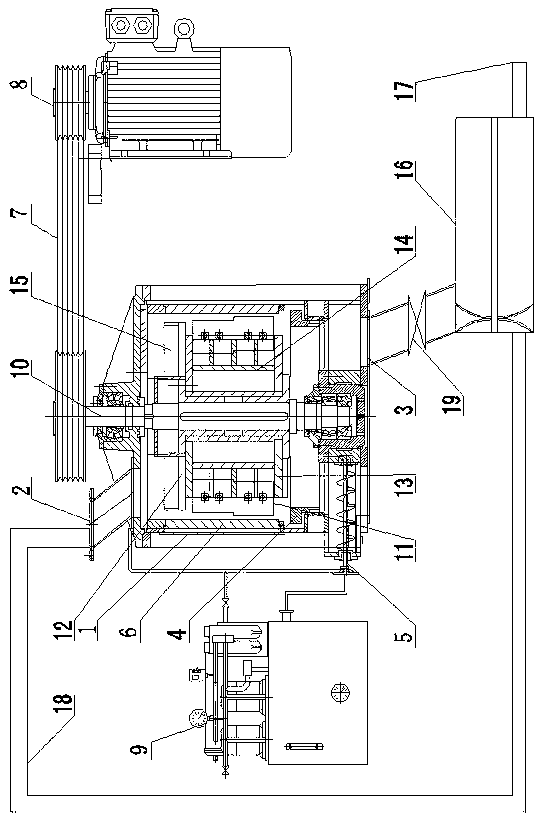

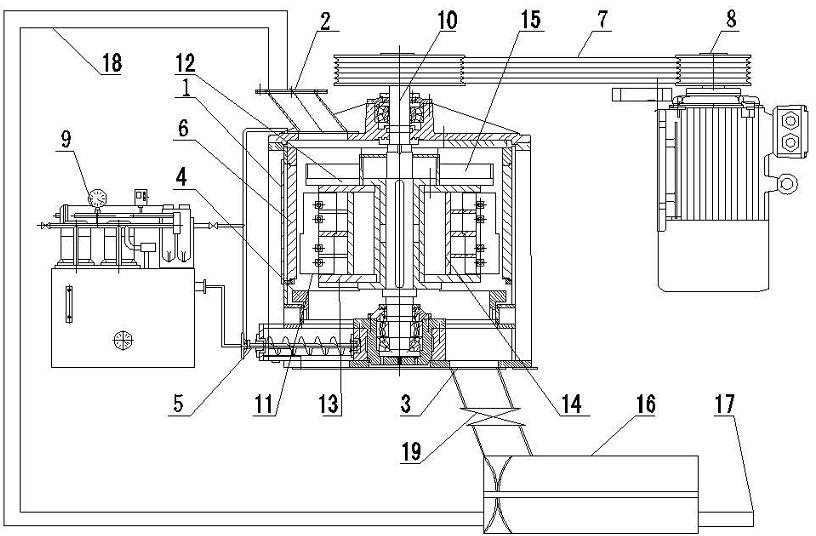

[0017] as attached figure 1 Shown: the integrated crushing, grinding and grading machine of the present invention includes a crushing mill, the discharge port 3 of the crushing mill is connected to the classifier 16 through the discharge pipeline, and the described classifier is connected to the overflow pipe 17 , the classifier is connected to the pulverizer through a return pipeline 18, a sampler 5 is installed at the outlet of the pulverizer, and a flow control valve 19 is installed on the discharge pipeline.

Embodiment 2

[0019] The crushing, grinding, and grading integrated machine, the crushing machine includes a shell 1, the upper part of the shell has a feed port 2, and the lower part of the shell has the above-mentioned discharge port 3, There is a closed ring 4 under the casing at the discharge port, a counterattack plate 6 is installed on the inner wall of the casing, and a rotor assembly is installed inside the casing, and the rotor assembly is connected by a belt 7 Its drive mechanism 8 and the rotor assembly are connected to a thin oil lubrication system 9 .

Embodiment 3

[0021] In the crushing, grinding and grading integrated machine, the rotor assembly includes a mandrel 10, the mandrel is installed with a rotor frame 14, and the grinding hammer head 11 is installed in the middle of the rotor frame. The guard plate 12 and the crushing hammer head 15 are connected above the rotor frame, and the rotor sealing blade 13 is connected below the rotor frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com