Outer rotor structure

An external rotor, integrated technology, applied in the direction of casing/housing/support, electrical components, electromechanical devices, etc., can solve the problem that the motor magnetic field cannot be greatly utilized, the stator core yoke is reduced, the stator core yoke is small, etc. problem, to achieve the effect of improving motor efficiency, simplifying the processing procedure, and increasing the width of the yoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

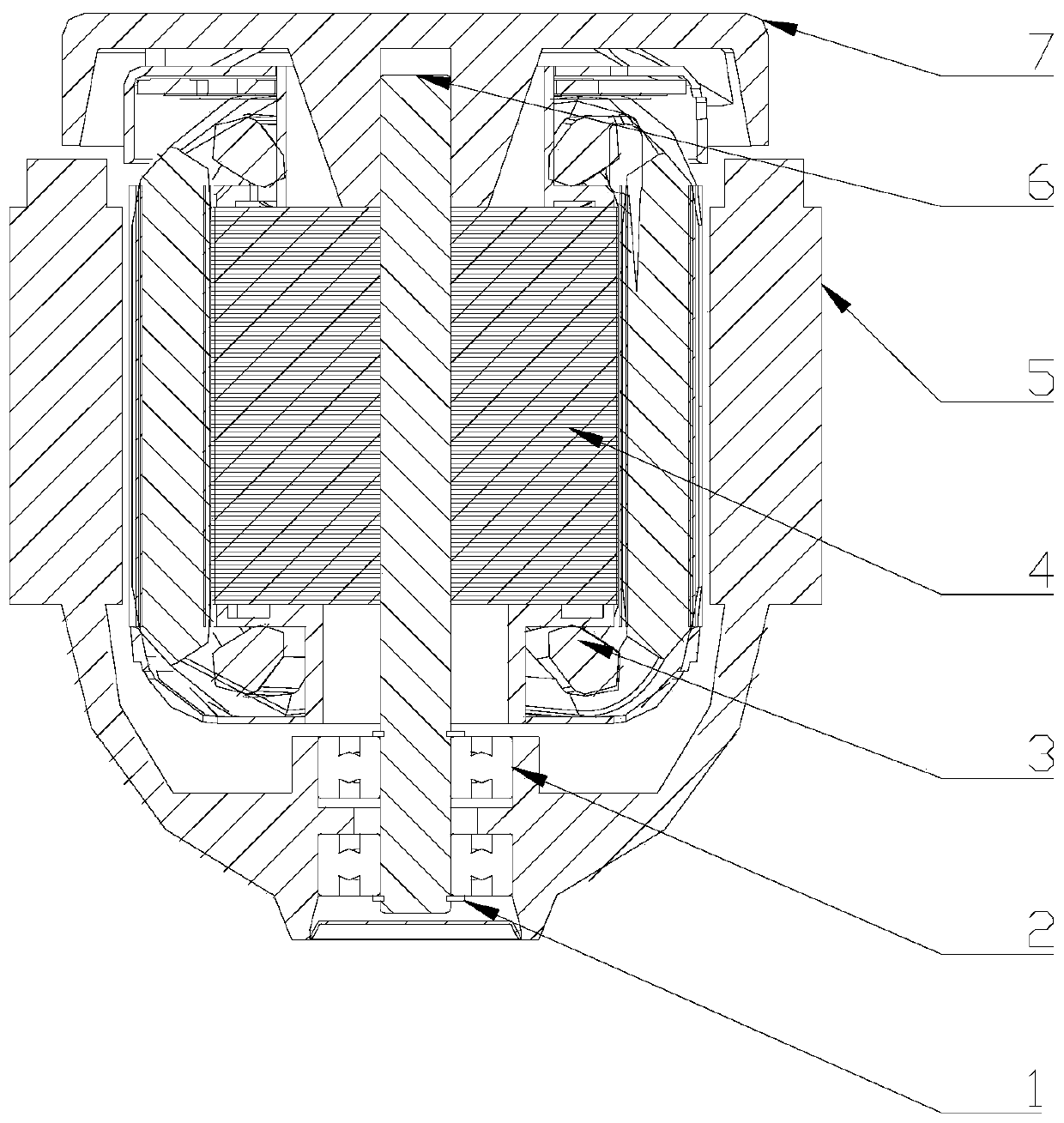

[0020] refer to Figure 1-2 , this embodiment discloses an outer rotor structure, including a first end cover 7, a shaft 6, an outer rotor 5, a stator core 4, a winding 3, two bearings 2 and two snap springs 1; the outer rotor 5 The integrally formed outer rotor 5 simplifies the assembly process of an end cover and the outer rotor. One axial end of the outer rotor 5 is provided with two concave cavities, that is, bearing chambers for installing the bearing 2. The one The concave cavity faces the inside of the outer rotor 5, and the other cavity faces the outside of the outer rotor 5. The two concave cavities are separated by a raised structure, and the other axial end of the outer rotor 5 is Fully open structure, the middle part of the outer rotor 5 is connected with the end with a concave cavity through an arc structure, and a cavity is formed inside the outer rotor 5 for installing other components. The outer walls of the outer rings of the two bearings 2 are interference f...

Embodiment 2

[0024] This embodiment discloses an outer rotor structure, including a first end cover 7, a second end cover, a shaft 6, an outer rotor 5, a stator core 4, a winding 3, two bearings 2 and two retaining springs 1; The outer rotor 5 of the embodiment is a split structure, that is, the second end cover and the outer rotor 5 are detachably assembled, and the second end cover is made of aluminum, which facilitates the second end cover and the outer rotor 5 The assembly of the outer rotor 5 is also convenient for the assembly of other components inside; the second end cover is provided with two cavities, that is, the bearing chamber for installing the bearing 2, and the one cavity faces the outer rotor 5 The other concave cavity faces the outside of the outer rotor 5, and the two concave cavities are separated by a raised structure. The axial ends of the outer rotor 5 are fully open structures, and the second The end cover is fixedly connected to one end of the outer rotor 5, the ou...

Embodiment 3

[0028]This embodiment discloses an outer rotor structure, including a first end cover 7, a second end cover, a shaft 6, an outer rotor 5, a stator core 4, a winding 3, two bearings 2 and two retaining springs 1; The outer rotor 5 of the embodiment is a split structure, that is, the second end cover and the outer rotor 5 are detachably assembled, the material of the second end cover is iron, and the axial ends of the outer rotor 5 are full Open structure, the second end cover is tightly fitted outside the outer rotor 5, that is, the outer rotor 5 is surrounded except for one end in the axial direction. Since the material of the second end cover is iron, Such setting can increase the magnetic conduction area. When increasing the width of the yoke of the stator core 4 to increase the magnetic field, the magnetic field can be further increased, thereby further improving the efficiency of the motor. Two recesses are arranged in the second end cover. cavity, that is, the bearing cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com