Transfer robot system

A technology for handling robots and manipulators, applied in manipulators, manufacturing tools, etc., can solve problems such as work efficiency bottlenecks, easy swinging of workpieces, and difficulty in adjusting the angle of workpieces, so as to reduce the cost of human resources, improve production efficiency, and reduce hidden dangers of safety accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

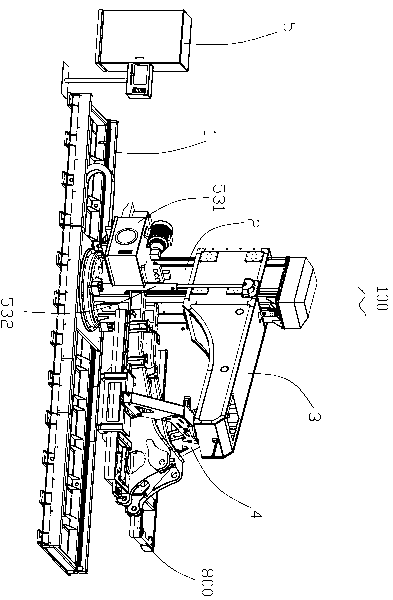

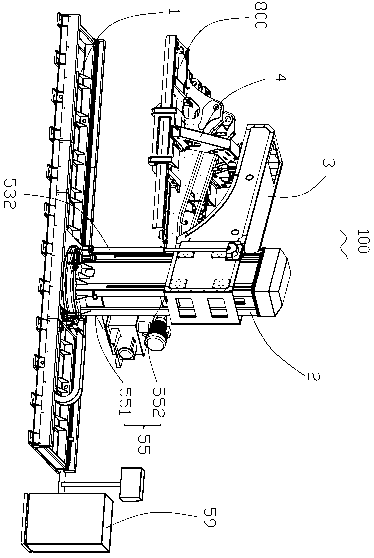

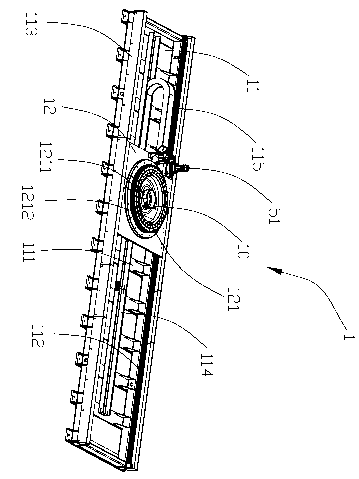

[0034] Please refer to figure 1 and figure 2 Shown is a first preferred embodiment of the handling robot system 100 of the present invention. The handling robot system 100 is used for handling large and heavy workpieces 800, and includes a base 1, a rotating column 2 that is movably positioned on the base 1 and vertically arranged with the base 1, and is installed vertically on the rotating column 2 and along the rotating column 2. The cantilever 3 moving up and down in the axial direction, the manipulator 4 movable and fixed at the end of the cantilever 3, and the control device 5 for controlling the rotation an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com