Amplitude-variable bagged loading machine

A technology for loading machines and lifting blocks, which is applied in the field of mechanical equipment and can solve problems such as the limitation of the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

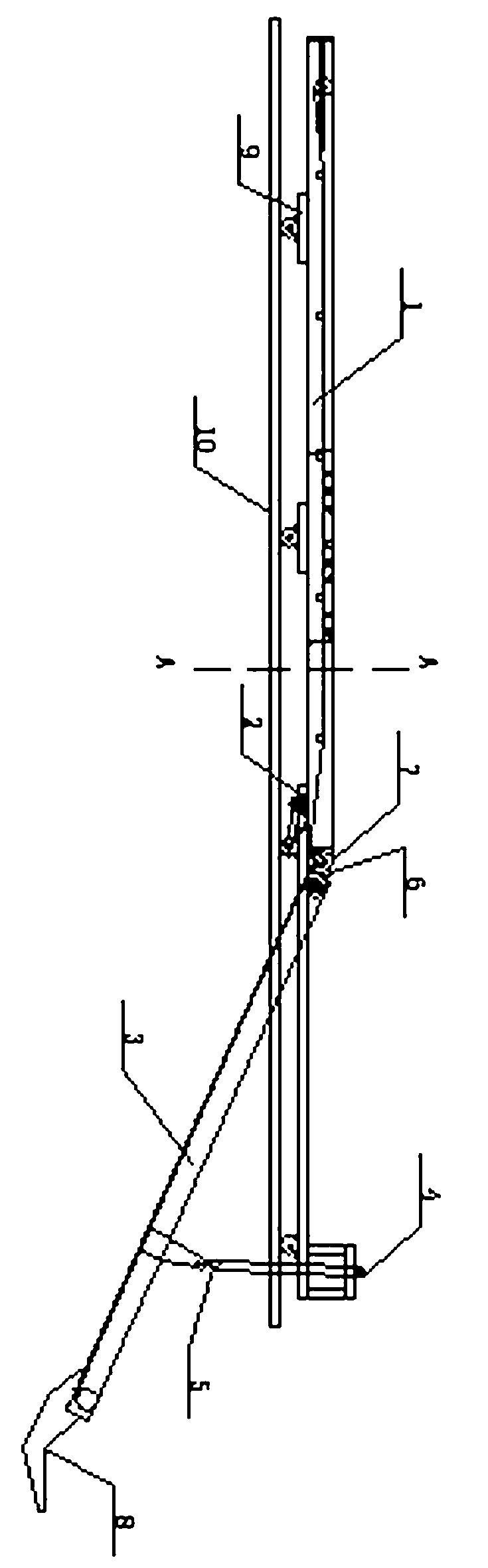

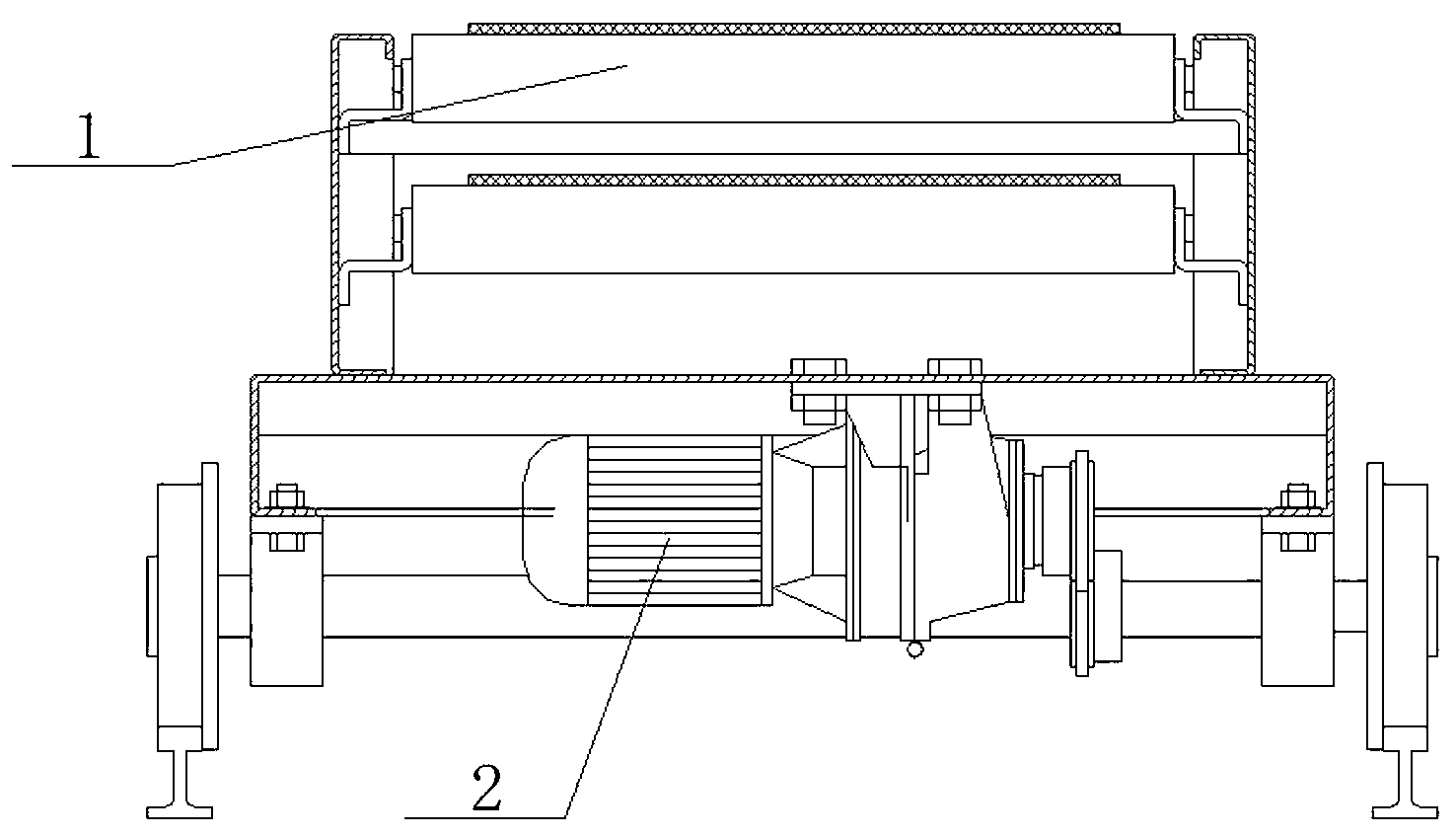

[0011] refer to figure 1 , figure 2 , the specific embodiment adopts the following technical solutions: a luffing type bag loading machine, which includes a horizontal conveying tape device 1, at least two groups of walking wheels 9 are provided at the bottom of the horizontal conveying tape device 1, and the walking The wheel 9 is connected with the traveling drive device 2 through the chain 7, and the end of the horizontal conveying belt device 1 is connected with the luffing belt device 3 through the transition support roller 6, and the luffing belt device 3 is connected with the lifting block 5, so The lifting block 5 is connected to the hoist 4 , and the end of the luffing tape device 3 is provided with a discharge port 8 .

[0012] The walking driving device 2 is a motor reducer, which is convenient to drive the traveling wheels to move.

[0013] The transition support roller 6 is injection molded by reinforced nylon, which has the characteristics of strong wear resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com