Safe monitoring device of winding engine

A technology for safety monitoring and hoisting, which is applied in hoisting devices and clockwork mechanisms, etc. It can solve problems such as difficult maintenance, affecting production efficiency, and wire rope disorder, and achieves the effects of timely alarming and easy maintenance of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

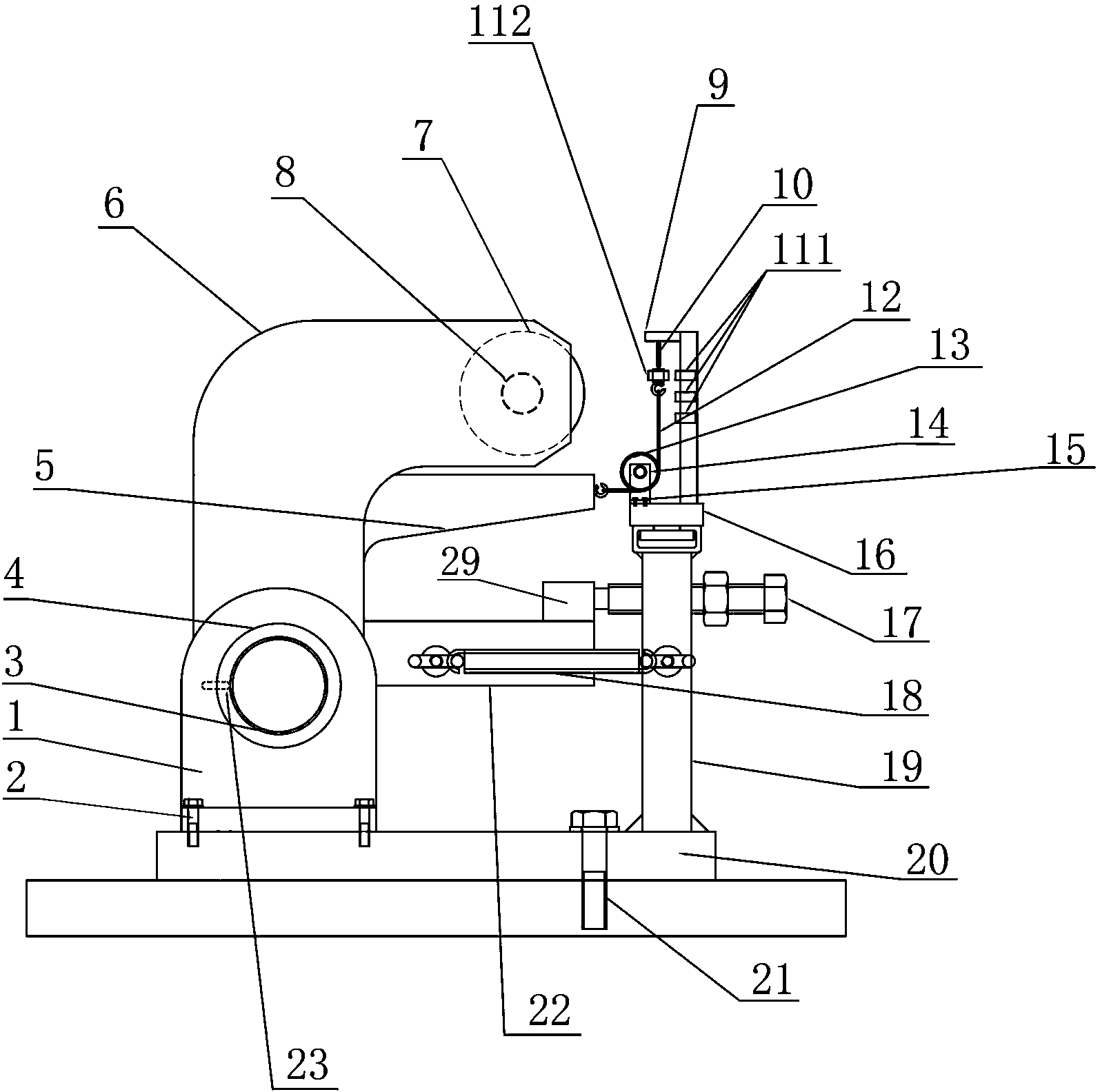

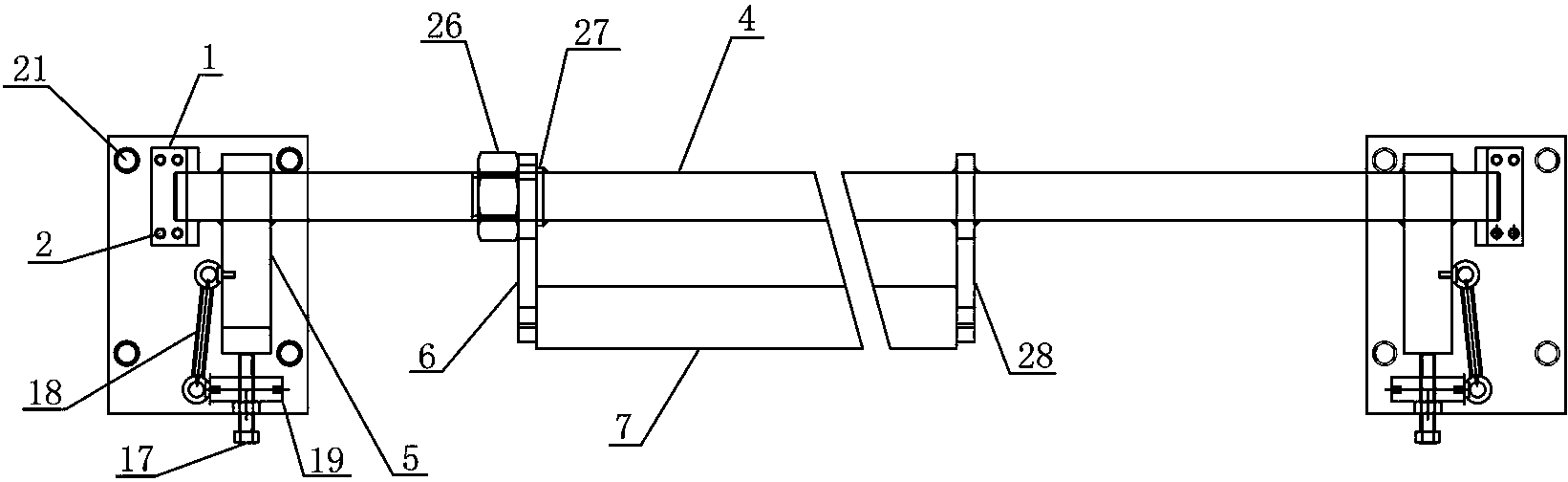

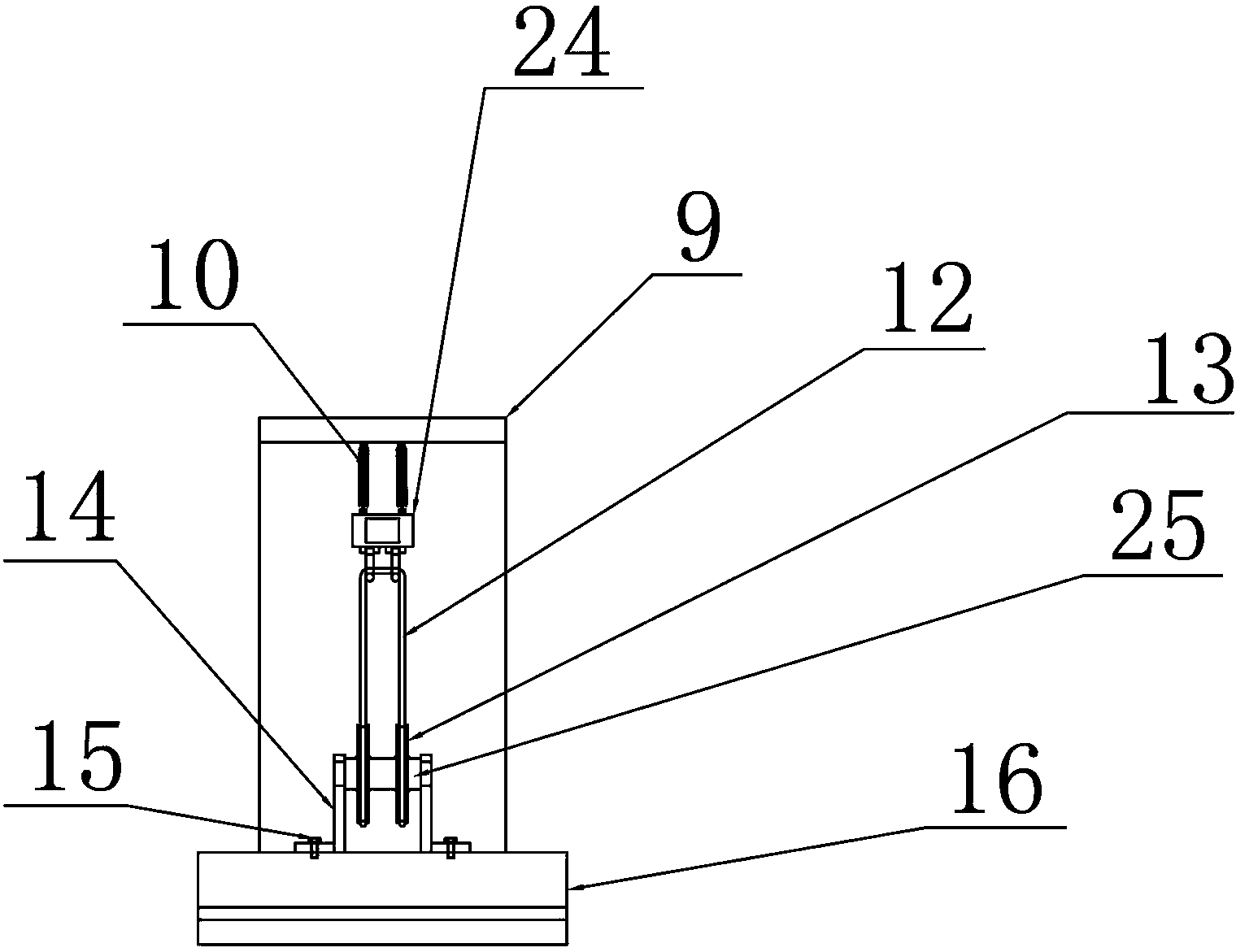

[0019] See attached figure 1 , attached figure 2 And attached image 3 , the present invention includes a base 20, the base 20 is provided with a rotating support 1, the rotating support 1 is provided with a rotating shaft journal 3 and a rotating shaft 4, and one end of the position sensing device 6 is installed on the rotating shaft 4 through a fixed key 23, The rotating support 1 is installed on the base 20 through the fixing screw 2. The position sensing device 6 is in an inverted "L" shape as a whole, and the other end is bent inward. The end is provided with a position sensing rod 8, and a guide Roller 7 and guide roller 7 lean against the steel wire of the hoist. When the wire rope of the hoist is out of position, the wire rope protruding from the rope groove exerts an outward thrust on the guide roller 7. At this time, the guide roller 7 is stressed and drives the position sensing device 6 rotates around the rotating shaft 4 to realize the induction of the misalignm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com