Indoor-GPS-based (indoor global positioning system-based) stress-free assembly system for large-size airplane parts, and application thereof

A technology of assembly system and large parts, applied in the field of aircraft assembly and aviation manufacturing engineering, it can solve the problems of inability to adapt to the development of new generation aircraft technology, and achieve the effect of stress-free assembly, automation, small footprint, and improved measurement efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

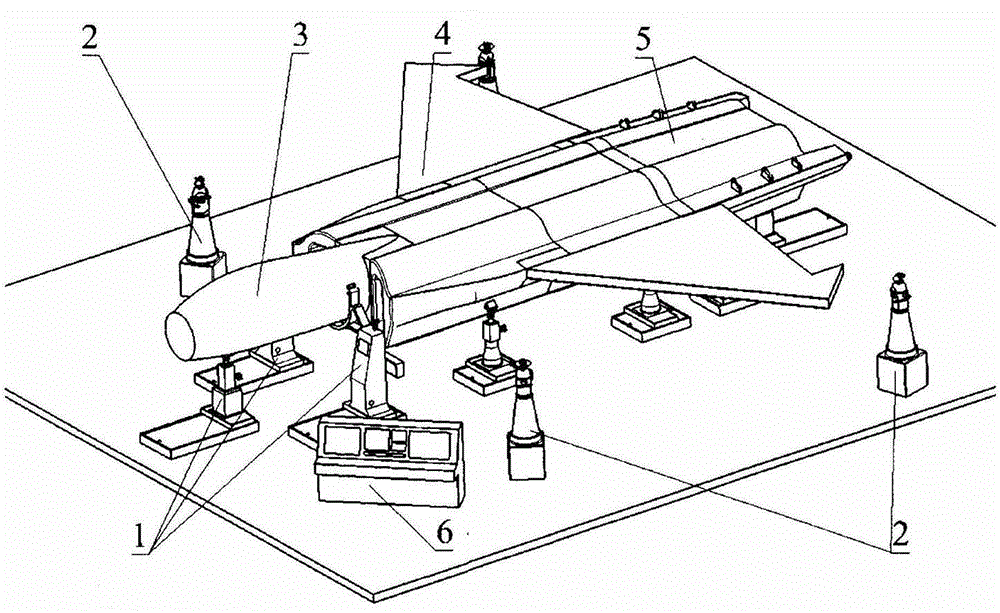

[0019] Such as figure 1 As shown, the stress-free assembly system for large aircraft parts based on indoor GPS includes automatic control system 6, digital measurement and inspection system 2, numerical control execution system 1 and three-dimensional stress detection system, digital measurement inspection system 2, numerical control execution system 1 and three-dimensional stress detection system The detection system transmits data information with the automatic control system 6 respectively.

[0020] The digital measurement and inspection system 2 includes an indoor GPS and a laser tracker, and the indoor GPS receiver and the target ball of the laser tracker are placed on each fuselage of the aircraft. Digital measurement and inspection system 2 builds a global precision control measurement platform based on indoor GPS based on the requirements of aircraft assembly process, and takes advantage of the advantages of indoor GPS measurement speed, wide measurement range, simulta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com