Novel humectant for tobacco and preparation method of humectant

A humectant for cigarettes, a new technology, applied in the field of new moisturizers for cigarettes and its preparation, to achieve good physical moisturizing effect, significant industrial application value and popularization and application, and improve the effect of roundness and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

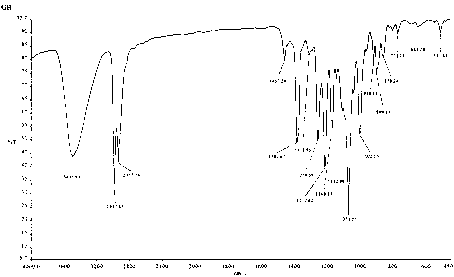

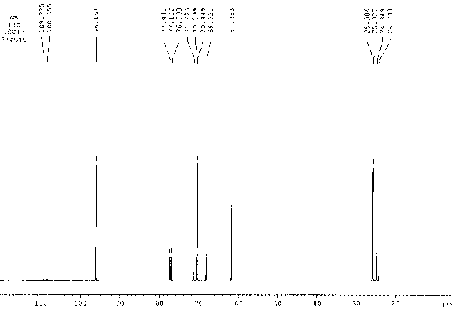

Image

Examples

Embodiment 1

[0043] A preparation method of a novel humectant for cigarettes, comprising the steps of:

[0044] (1) Preparation of 1,2:3,4-di-O-isopropylidene-α-D-galactopyranose (Ⅱ)

[0045]In a 1000mL three-neck flask, add 18g of dried D-galactose (I) and 360mL of anhydrous acetone, stir and mix evenly, and cool in an ice-water bath to lower the temperature of the mixture to 10°C. Then slowly add 9mL of concentrated sulfuric acid dropwise, control the rate of addition to prevent the reaction system from heating up too fast and cause side reactions, and keep the temperature below 10°C during the dropwise addition. After the concentrated sulfuric acid was added dropwise, the ice-water bath was removed, and the temperature was raised to about 15°C and stirred for 4 hours. After cooling in an ice-water bath to lower the reaction solution below 5 °C, 33.3% aqueous sodium hydroxide solution was added dropwise to adjust the pH of the reaction solution to 7. Subsequently, the reaction solution...

Embodiment 2

[0053] A preparation method of a novel humectant for cigarettes, comprising the steps of:

[0054] (1) Preparation of 1,2:3,4-di-O-isopropylidene-α-D-galactopyranose (Ⅱ)

[0055] In a 1000mL three-necked flask, add 18g of dried D-galactose (I) and 540mL of anhydrous acetone, stir and mix evenly, and cool in an ice-water bath to lower the temperature of the mixture to 5°C. Then slowly add 18mL of concentrated sulfuric acid dropwise, control the drop rate to prevent the reaction system from heating up too fast and cause side reactions, and keep the temperature below 10°C during the dropwise addition. After the concentrated sulfuric acid was added dropwise, the ice-water bath was removed, and the temperature was raised to about 35°C and stirred for 8 hours. After cooling in an ice-water bath to lower the reaction solution below 5°C, 33.3% aqueous sodium hydroxide solution was added dropwise to adjust the pH of the reaction solution to 8. Subsequently, the reaction solution was ...

Embodiment 3

[0063] A preparation method of a novel humectant for cigarettes, comprising the steps of:

[0064] (1) Preparation of 1,2:3,4-di-O-isopropylidene-α-D-galactopyranose (Ⅱ)

[0065] In a 1000mL three-necked flask, add 18g of dried D-galactose (I) and 400mL of anhydrous acetone, stir and mix evenly, and cool in an ice-water bath to lower the temperature of the mixture to 5°C. Then slowly add 12 mL of concentrated sulfuric acid dropwise, control the rate of addition to prevent the reaction system from heating up too fast and cause side reactions, and keep the temperature below 10°C during the dropwise addition. After the concentrated sulfuric acid was added dropwise, the ice-water bath was removed, and the temperature was raised to about 25°C and stirred for 6 hours. After cooling in an ice-water bath to lower the reaction solution below 5 °C, 33.3% aqueous sodium hydroxide solution was added dropwise to adjust the pH of the reaction solution to 7.5. Subsequently, the reaction so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com