Novel tobacco humectant 6-o-hydroxyethyl-d-galactopyranose and its preparation method

A technology of galactopyranose and humectant for tobacco, which is applied in the preparation of sugar derivatives, chemical instruments and methods, tobacco, etc., can solve the problem of unsatisfactory improvement of the moisture content of finished cigarettes, affecting the taste, low temperature and easy solidification And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method for humectant 6-O-hydroxyethyl-D-galactopyranose for cigarettes, comprising the steps of:

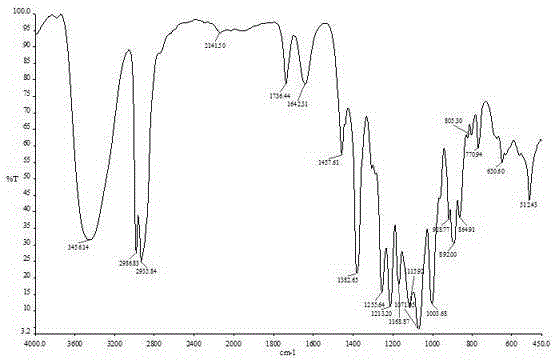

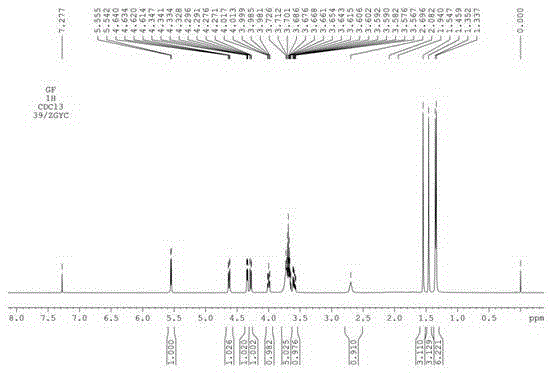

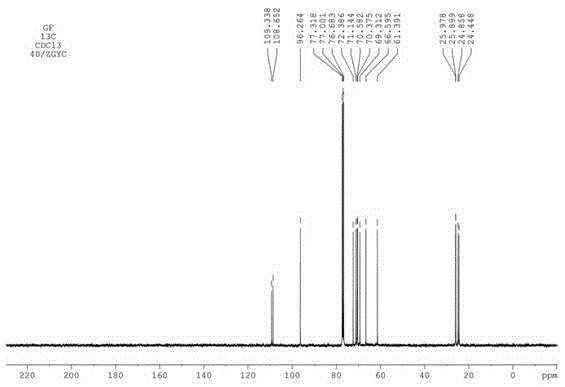

[0031] (1) Preparation of 6-O-hydroxyethyl-1,2:3,4-di-O-isopropylidene-α-D-galactopyranose (Ⅱ)

[0032] Weigh 6.0 g of 6-O-carboxymethyl-1,2:3,4-di-O-isopropylidene-α-D-galactopyranose tert-butyl ester (Ⅰ) into a 250 mL three-necked flask, add 60mL of tetrahydrofuran (THF), magnetic stirring to dissolve, then nitrogen protection, ice-water bath cooling to below 10 ℃ (preferably between 0-10 ℃), and then slowly add LiAlH 4 0.03mol, raise the temperature and react at 10°C for 7h, TLC monitors the entire reaction process (V 石油醚 :V 乙酸乙酯 =3:2), then slowly drop 18mL of 70% ethyl acetate aqueous solution to end the reaction, filter the precipitate, and concentrate under reduced pressure to obtain 3.54g of a colorless transparent viscous liquid intermediate (Ⅱ), with a yield of 72.53% .

[0033] (2) Preparation of 6-O-hydroxyethyl-D-galactopyranose (Ⅲ)

[0034]...

Embodiment 2

[0036] A preparation method for humectant 6-O-hydroxyethyl-D-galactopyranose for cigarettes, comprising the steps of:

[0037] (1) Preparation of 6-O-hydroxyethyl-1,2:3,4-di-O-isopropylidene-α-D-galactopyranose (Ⅱ)

[0038] Weigh 6.0 g of 6-O-carboxymethyl-1,2:3,4-di-O-isopropylidene-α-D-galactopyranose tert-butyl ester (Ⅰ) into a 250 mL three-necked flask, add Dissolve 90mL of tetrahydrofuran (THF) with magnetic stirring, then pass nitrogen protection, cool in an ice-water bath to below 10°C (preferably between 0-10°C), and then slowly add LiAlH 4 0.033mol, raise the temperature and react at 20°C for 8h, TLC monitors the entire reaction process (V 石油醚 :V 乙酸乙酯 =3:2), then slowly drop 20mL of 50% by volume ethyl acetate aqueous solution (V 乙酸乙酯 :V 水 =1:1) to complete the reaction, filter the precipitate, and concentrate under reduced pressure to obtain 4.49 g of a colorless transparent viscous liquid intermediate (II), with a yield of 92.07%.

[0039] (2) Preparation of 6-...

Embodiment 3

[0042] A preparation method for humectant 6-O-hydroxyethyl-D-galactopyranose for cigarettes, comprising the steps of:

[0043] (1) Preparation of 6-O-hydroxyethyl-1,2:3,4-di-O-isopropylidene-α-D-galactopyranose (Ⅱ)

[0044] Weigh 6.0 g of 6-O-carboxymethyl-1,2:3,4-di-O-isopropylidene-α-D-galactopyranose tert-butyl ester (Ⅰ) into a 250 mL three-necked flask, add Dissolve 120mL of THF with magnetic stirring, then pass nitrogen protection, cool in an ice-water bath to below 10°C (preferably between 0-10°C), then slowly add LiAlH 4 0.036mol, raise the temperature and react 9h at room temperature, TLC monitors the whole reaction process (V 石油醚 :V 乙酸乙酯 =3:2), then slowly drop 24mL of 30% by volume ethyl acetate aqueous solution (V 乙酸乙酯 :V 水 =1:1) to complete the reaction, filter the precipitate, and concentrate under reduced pressure to obtain 4.35 g of a colorless transparent viscous liquid intermediate (II), with a yield of 89.12%.

[0045] (2) Preparation of 6-O-hydroxyethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com