Glass fiber reinforced styrene-acrylonitrile-N-phenylmaleimide-cyclic olefin copolymer compound

A technology of maleimide and glass fiber, which is applied in the field of polymer modification, can solve the problems of high heat distortion temperature of glass fiber reinforced heat-resistant SAN, and achieve excellent mechanical properties, good transparency, and high heat distortion temperature. Effect

Active Publication Date: 2012-10-03

ZHEJIANG OCEANKING DEVELOPMENT CO LTD

View PDF4 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The glass fiber reinforced heat-resistant SAN obtained in the present invention has relatively high thermal de

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

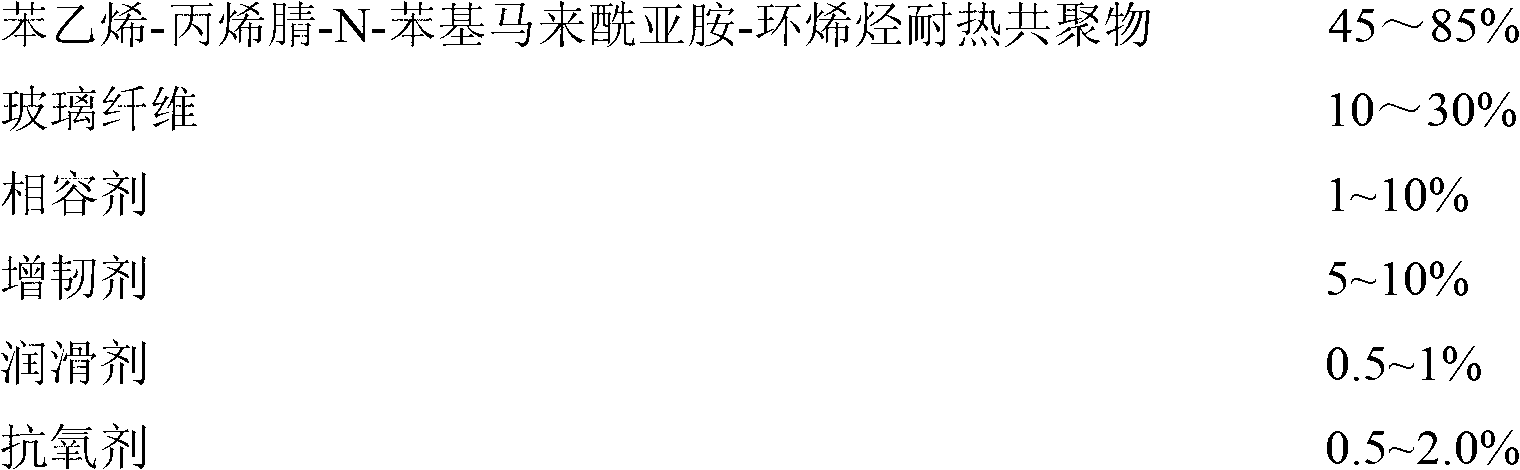

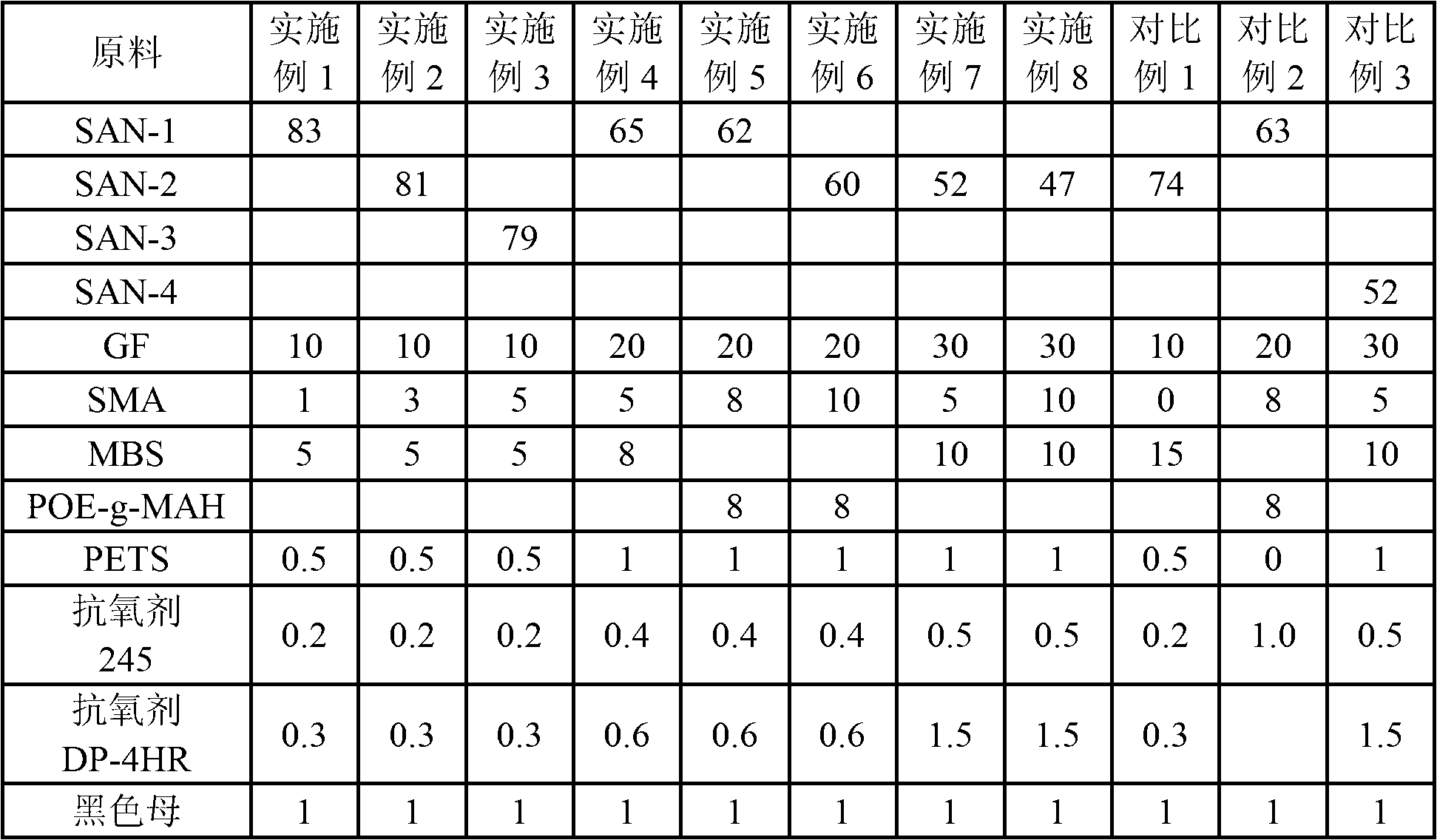

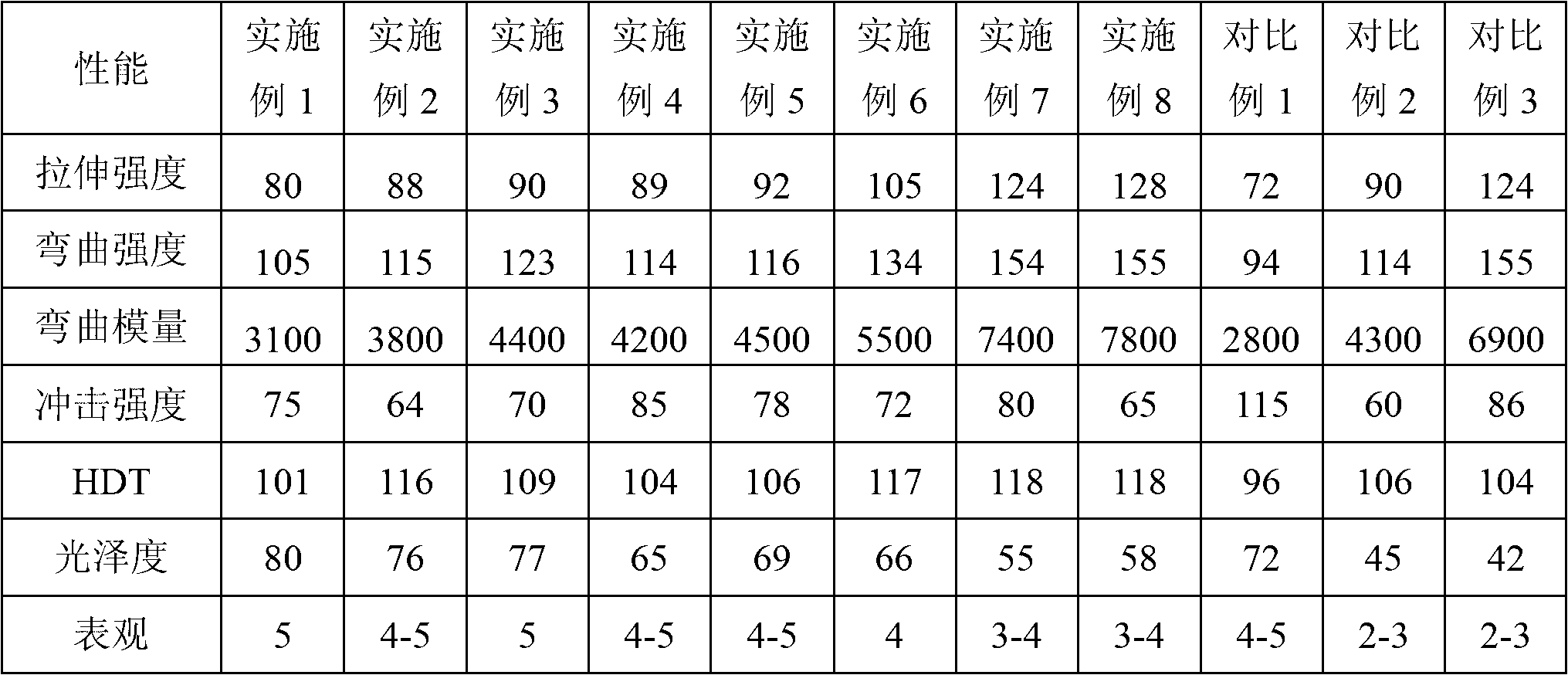

The invention relates to a glass fiber reinforced styrene-acrylonitrile-N-phenylmaleimide-cyclic olefin copolymer compound, which is characterized by comprising the following components in weight ratio: 45-85 percent of styrene-acrylonitrile-N-phenylmaleimide-cyclic olefin heat resistant copolymer, 10-30 percent of glass fiber, 1-10 percent of compatilizer, 5-10 percent of toughening agent, 0.5-1 percent of lubricant and 0.5-2.0 percent of antioxidant. Compared with the prior art, the problems of the existing reinforced SAN resin surface floating fiber with high glass fiber content and the like are basically solved by the glass fiber reinforced styrene-acrylonitrile-N-phenylmaleimide-cyclic olefin heat resistant copolymer provided by the invention. The glass fiber reinforced styrene-acrylonitrile-N-phenylmaleimide-cyclic olefin copolymer compound has the advantages of higher thermal deformation temperature, excellent mechanical property and transparency and proper cost, and can be widely used in the fields of electronics, electrical appliances, instruments, illumination, automobile parts and the like.

Description

technical field [0001] The invention relates to the field of polymer modification, in particular to a glass fiber reinforced styrene-acrylonitrile-N-phenylmaleimide-cycloolefin copolymer composition. Background technique [0002] With the development of the automobile industry and technological progress in the fields of electronics and home appliances, the demand for heat-resistant high-strength plastics has gradually increased. Glass fiber reinforced styrene-acrylonitrile copolymer (GF-SAN) is very good in the field of household appliances because of its high heat distortion temperature, good processability, dimensional stability and tensile strength, and low production cost. Its application value, such as the production of axial flow, cross flow and centrifugal fan blades in air conditioners, or the production of instrument panels, instrument lenses, lighters, battery boxes and other products. Filling glass fiber can enhance the performance of the material, but it will ha...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L25/12C08K13/06C08K9/06C08K7/14C08K5/524B29C47/92B29C48/92

CPCB29C48/40B29C48/92B29C2948/9259B29C2948/92704B29C2948/92723B29C2948/92885B29C2948/92895

Inventor 沈曙光杜旭华周文斌邱琪浩方义红王振

Owner ZHEJIANG OCEANKING DEVELOPMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com