Telescopic seam connecting method for transverse paving single-layer metal wall surface plate

A connection method and metal wall technology, applied in the direction of walls, building components, building thermal insulation materials, etc., can solve the problems of insufficient facade effect, poor deformation resistance, inability to expand and contract, etc., to improve on-site construction efficiency and unique advantages. , the effect of saving installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

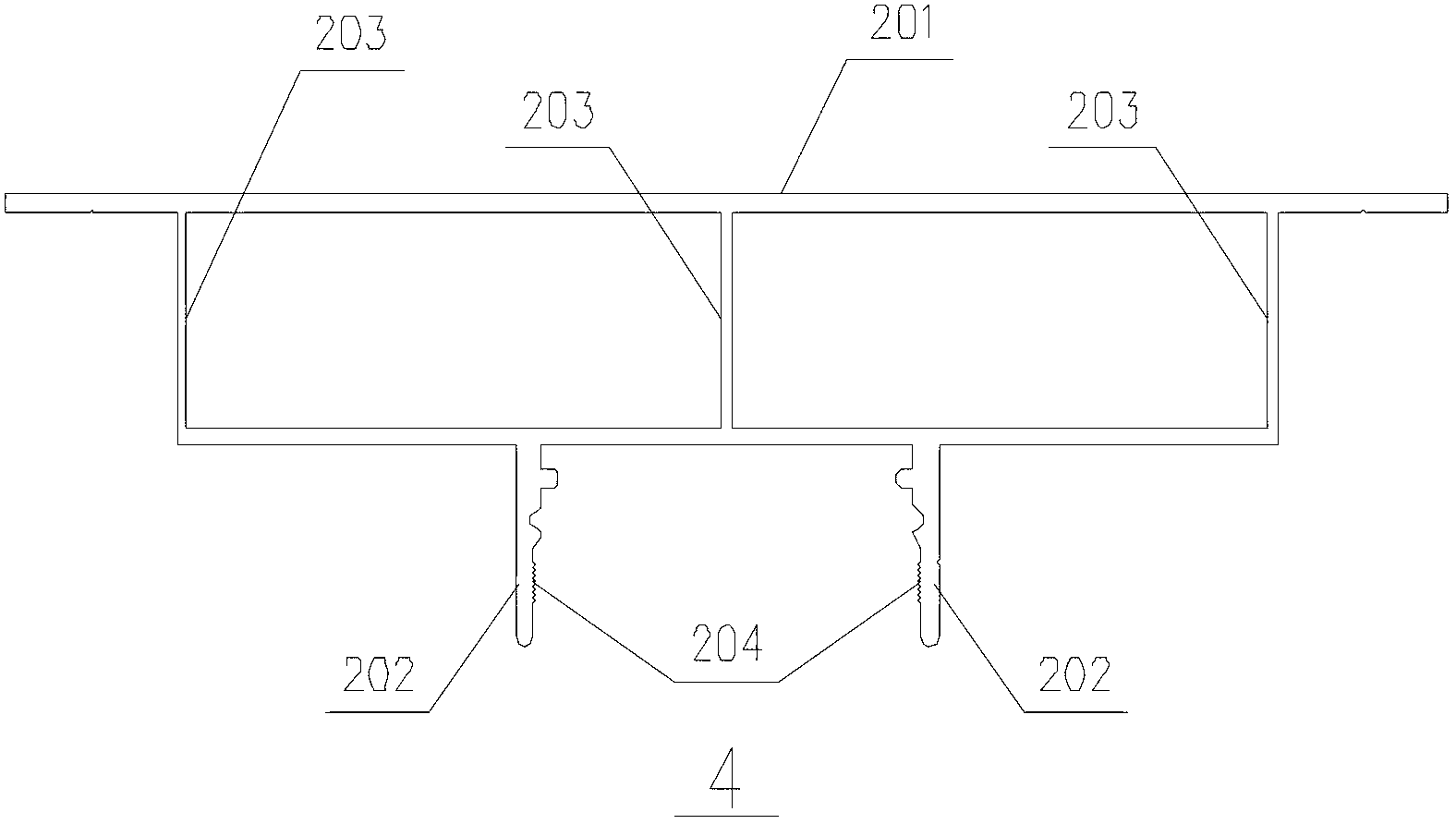

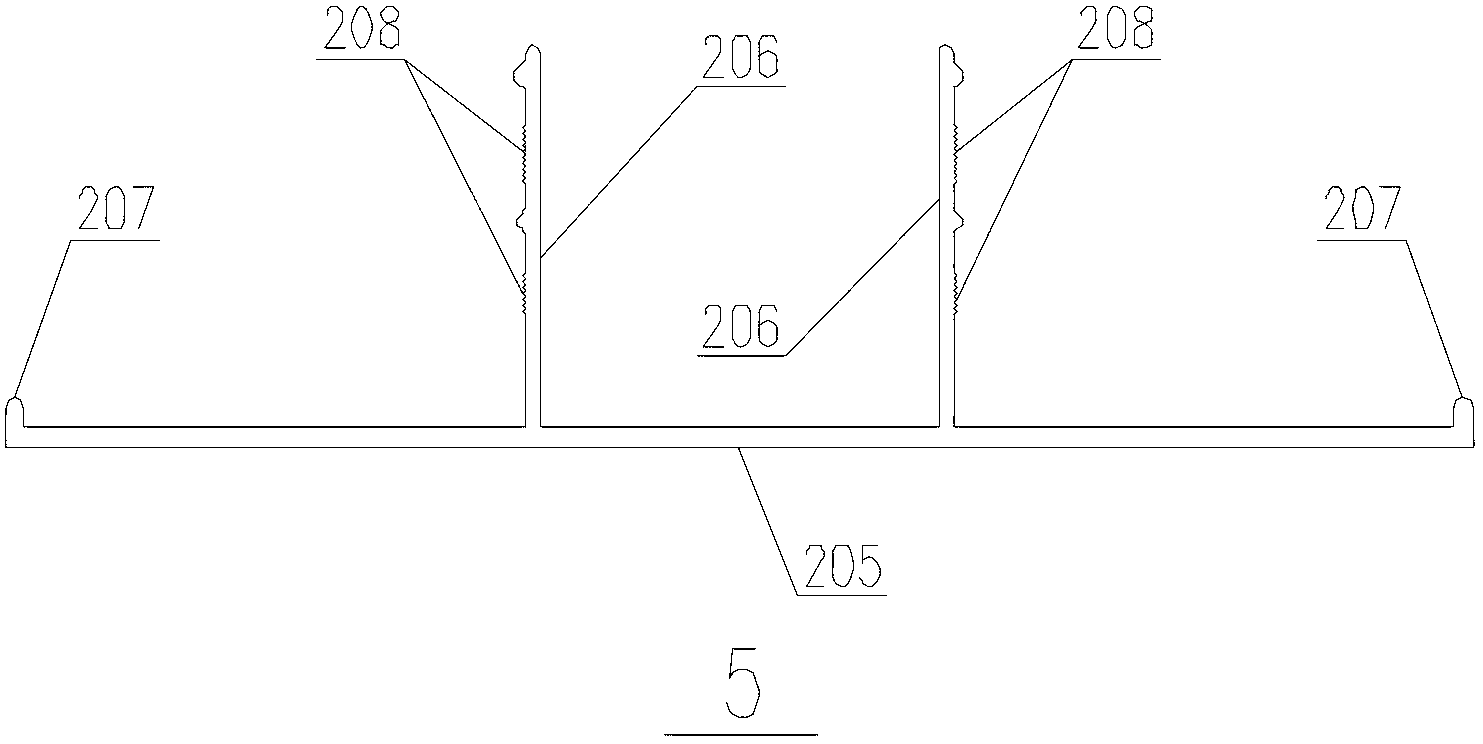

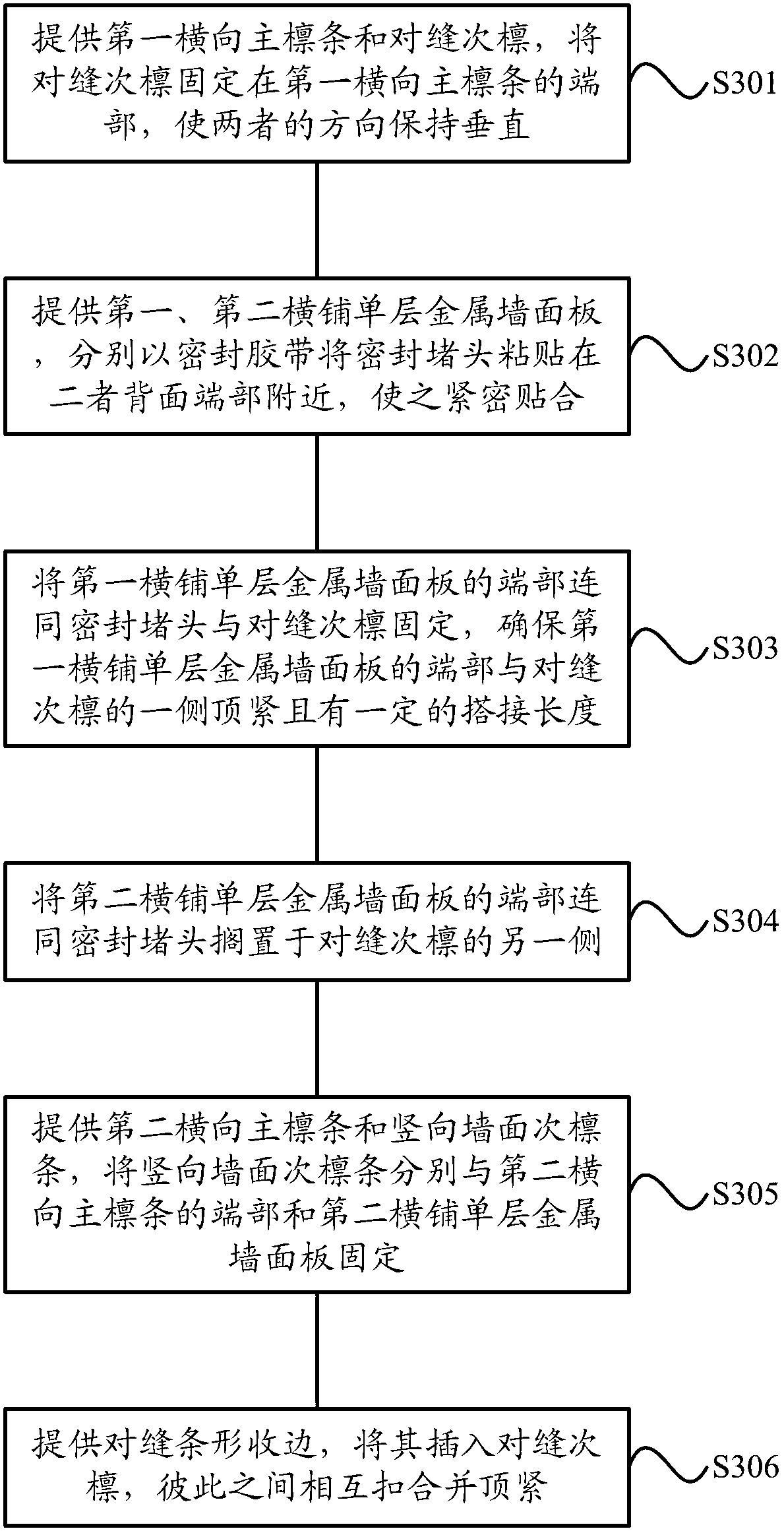

[0030] The connection method of the present invention effectively adapts to the deformation of the wall surface caused by the main structure of the building due to thermal expansion and contraction, settlement, etc., and makes the connection of the horizontal metal wall panels more firm; at the same time, the connection method can hide the burrs at the cutting part of the wall panels On the inner side of the aluminum alloy seam strip shape, making the connection more beautiful.

[0031] The present invention will be further described below in conjunction with specific embodiment and accompanying drawing, set forth more details in the following description so as to fully understand the present invention, but the present invention can obviously be implemented in many other ways different from this description, Those skilled in the art can make similar promotions and deductions based on actual application situations without violating the connotation of the present invention, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com