A semiconductor diode forming system

A diode and semiconductor technology, applied in the field of semiconductor diode molding systems, can solve the problems of the sharpness of the molding knife edge not being improved, the diode cannot be pre-clamped, the diode cannot be pre-cut, etc., so as to improve the shearing effect and the clamping effect. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

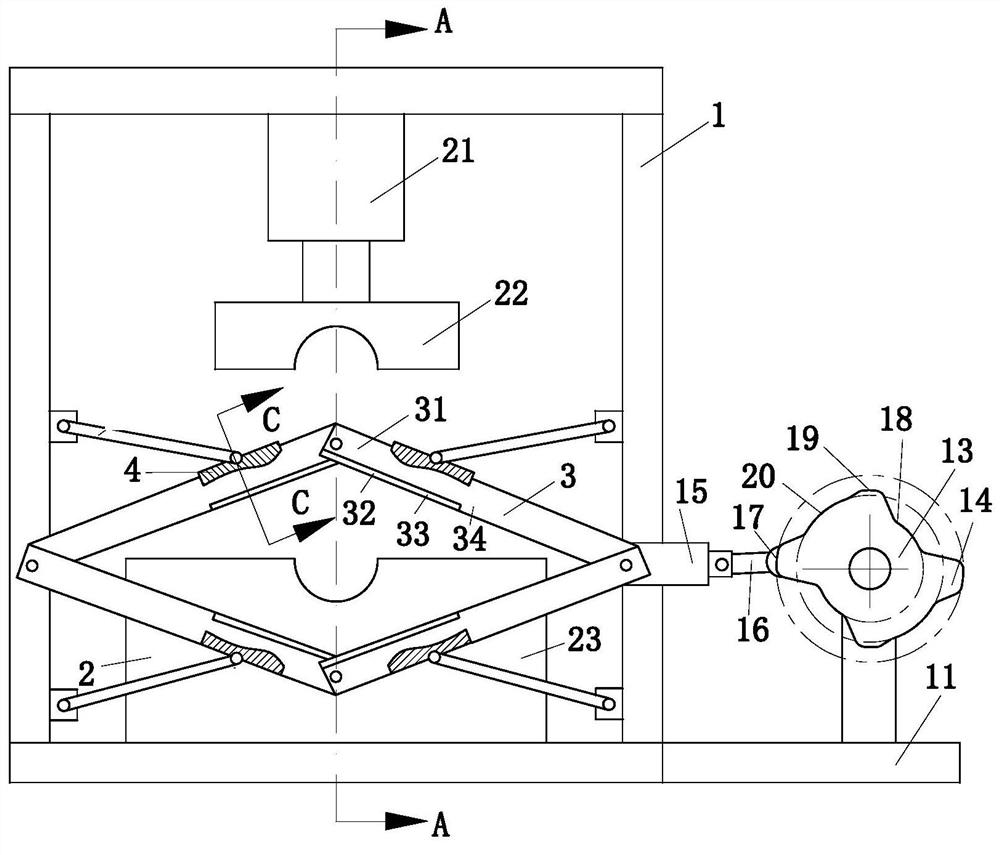

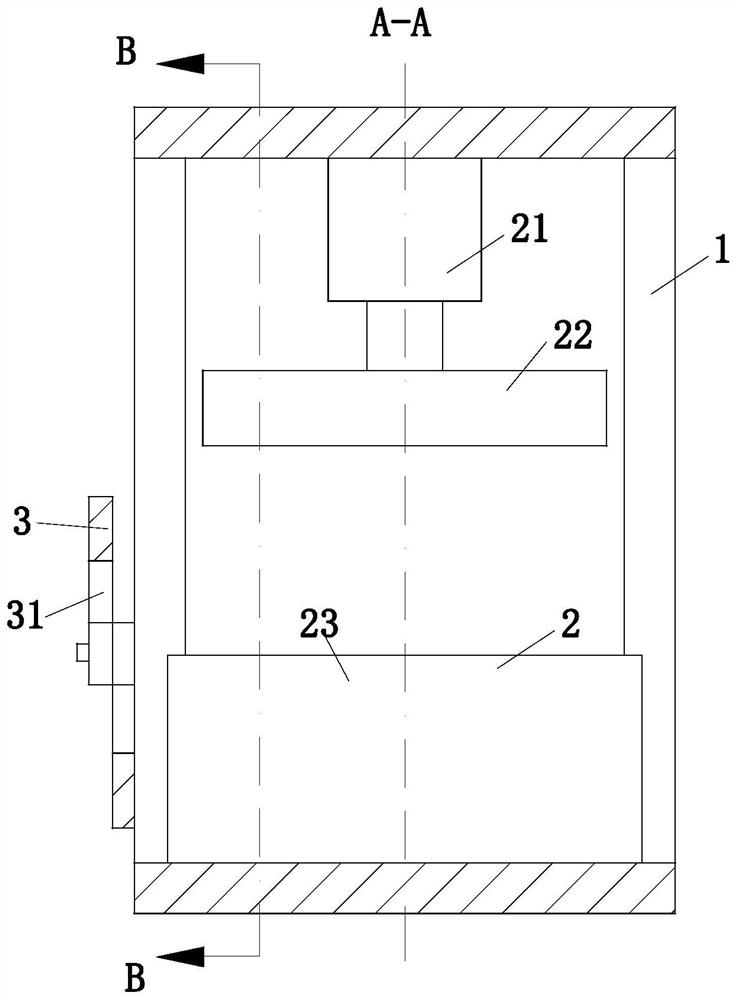

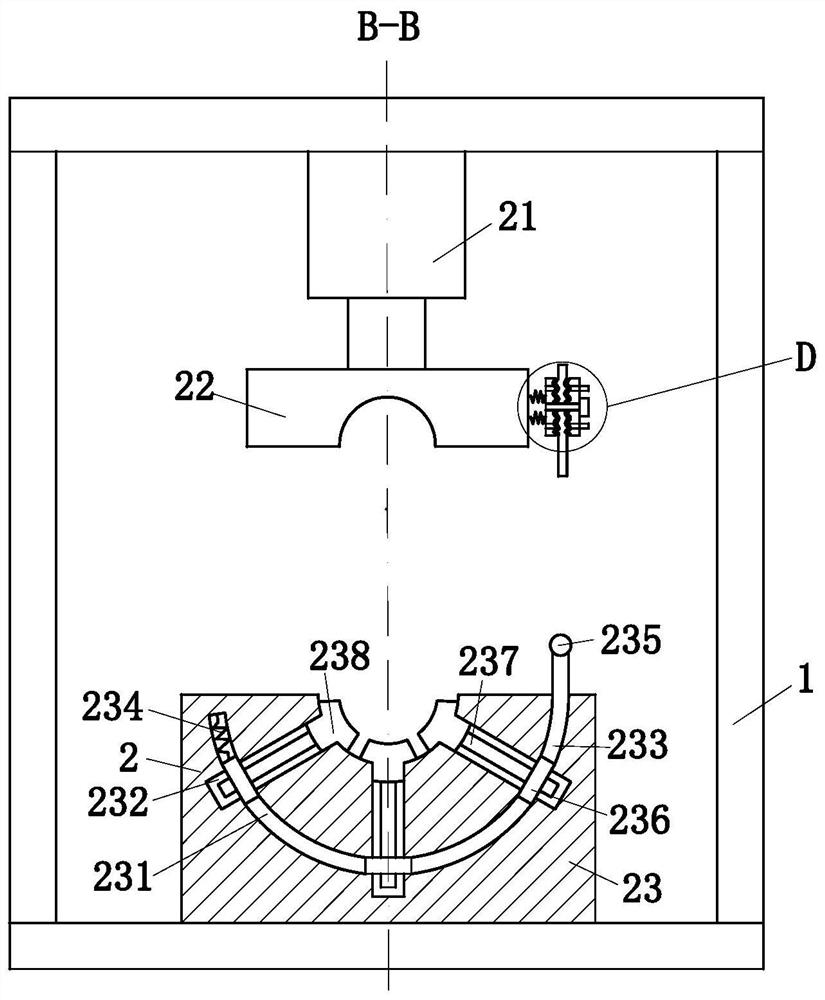

[0025] As an embodiment of the present invention, the outer ring of the No. 1 rotating wheel 13 is composed of two symmetrical No. 1 arcs 14, two symmetrical No. 2 arcs 18, two symmetrical No. 3 arcs 19 and two symmetrical The No. 4 arc 20 is formed; one side of the No. 3 arc 19 is adjacent to the No. 2 arc 18, and the other side of the No. 3 arc 19 is adjacent to the No. 4 arc 20; the No. 1 arc 14 is in the No. 2 arc Between the arc 18 and the fourth arc 20; the No. 1 rotating wheel 13 is provided with a No. 2 chute on the side, and the No. 2 slider 17 slides in the No. 2 chute; the No. 2 slider 17 is on the second The motion trajectory in the No. 2 chute produces different effects; first, when the No. 2 slider 17 is in the No. 1 arc position 14, the No. 2 plate 31 is fully opened at this time, and the forming knife 32 in the No. The diode does not have a shearing effect. When the No. 2 slider 17 moves to the position of the No. 2 arc 18, the No. 2 plate 31 is slowly closed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com